Gas hydrate accelerant and application thereof in saline-water desalting and carbon dioxide capturing

A gas hydrate and carbon dioxide technology, which is applied in specific gas purification/separation, gas treatment, carbon compounds, etc., can solve the problems of insufficient gas storage and low kinetics, and achieve improved stability, wide sources, and convenient industrial operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In this embodiment, an aqueous solution with a mass fraction of 0.5% methionine and 2% THF is used as a hydration accelerator, and the salt content is 2.0%.

[0030] The application of hydrate accelerator in brine desalination and carbon dioxide capture specifically includes the following steps:

[0031] 1) Uniformly mix 0.5g methionine, 2g THF and 97.5g brine (2g NaCl, 95.5g water) to obtain a mixed solution;

[0032] 2) Add 100g of the above mixed solution to the autoclave (effective volume: 500mL);

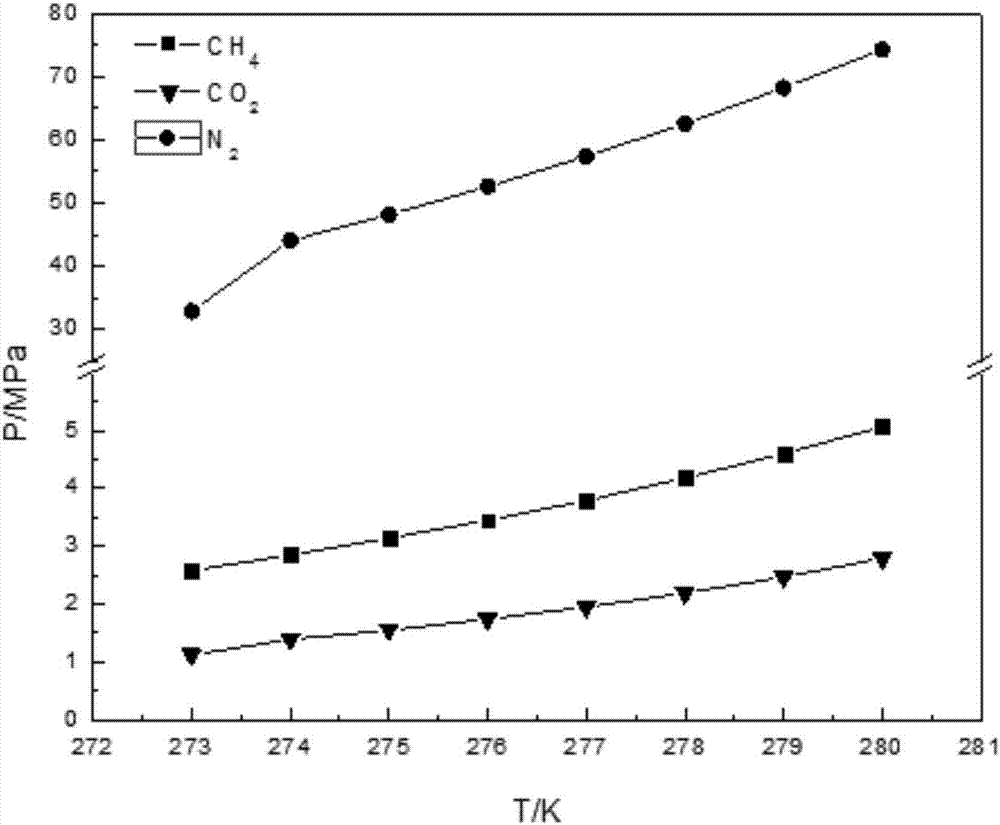

[0033] 3) at a temperature of 273K, filling the autoclave with a pressure of 5 MPa mixed gas (35% CH 4 , 65% CO 2 ), calculate the CO in the mixed gas at a certain time interval by the change of the pressure in the reactor 2 The content changes, the results are shown in Table 1; take out the gas hydrate;

[0034] 4) Under normal temperature and pressure, the gas hydrate naturally decomposes to obtain high-purity CO 2 Gas, collect the decomposed aqueous solution, mea...

Embodiment 2

[0037] In this embodiment, an aqueous solution with a mass fraction of 0.2% methionine and 2% THF is used as a hydration accelerator, and the salt content is 2.0%.

[0038] The application of hydrate accelerator in brine desalination and carbon dioxide capture specifically includes the following steps:

[0039] 1) Uniformly mix 0.2g methionine, 2g THF and 97.8g brine (2g NaCl, 95.8g water) to obtain a mixed solution;

[0040] 2) Add 100g of the above mixed solution to the autoclave (effective volume: 500mL);

[0041] 3) at a temperature of 273K, filling the autoclave with a pressure of 5 MPa mixed gas (35% CH 4 , 65% CO 2 ), calculate the CO in the mixed gas at a certain time interval by the change of the pressure in the reactor 2 The content changes, the results are shown in Table 1;

[0042] 4) Under normal temperature and pressure, the gas hydrate naturally decomposes to obtain high-purity CO 2 Gas, collect the decomposed aqueous solution, measure the salt content, the...

Embodiment 3

[0045] In this embodiment, an aqueous solution with a mass fraction of 0.01% methionine and 2% THF is used as a hydration accelerator, and the salt content is 2.0%.

[0046] The application of hydrate accelerator in brine desalination and carbon dioxide capture specifically includes the following steps:

[0047]1) Uniformly mix 0.01g methionine, 2g THF and 97.99g brine (2g NaCl, 95.99g water) to obtain a mixed solution;

[0048] 2) Add 100g of the above solution to the autoclave (500mL effective volume);

[0049] 3) at a temperature of 273K, filling the autoclave with a pressure of 5 MPa mixed gas (35% CH 4 , 65% CO 2 ), calculate the CO in the mixed gas at a certain time interval by the change of the pressure in the reactor 2 The content changes, the results are shown in Table 1;

[0050] 4) Under normal temperature and pressure, the gas hydrate naturally decomposes to obtain high-purity CO 2 Gas, collect the decomposed aqueous solution, measure the salt content, the res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com