Composite electrode material and application thereof

A composite positive electrode material and composite electrode technology, applied in the field of energy materials, can solve the problems of inability to carry out large-scale industrial production, low active material loading capacity, high preparation cost, etc., and achieve suitable for large-scale industrial production and output energy density High, promote the conduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

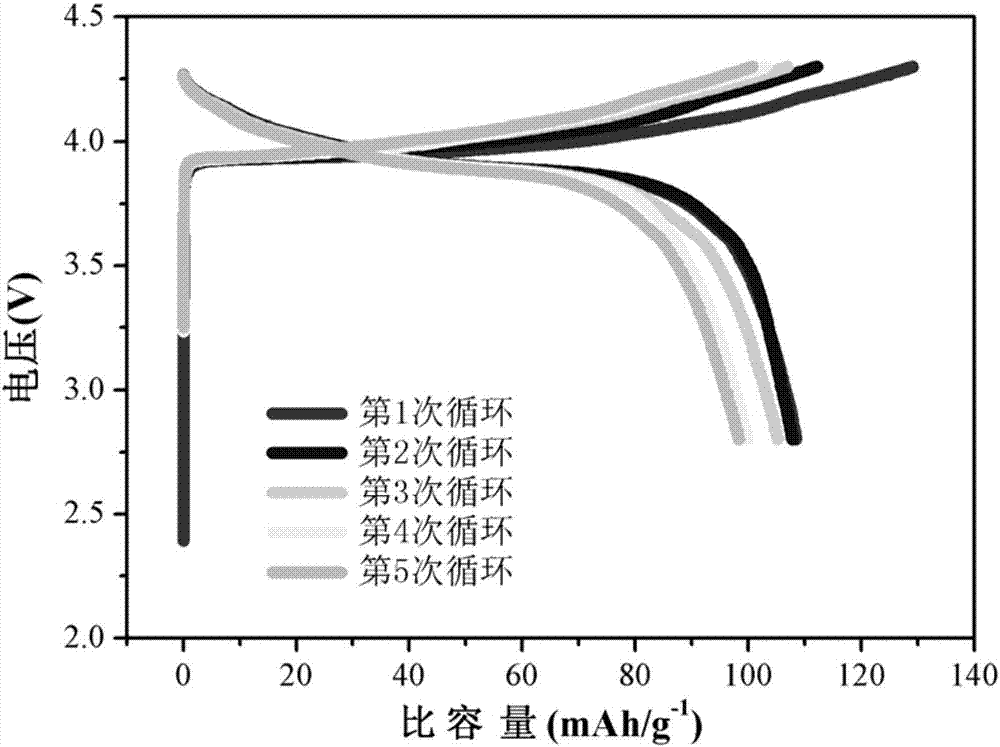

Embodiment 1

[0062] Using the method of the embodiment of the present invention, lithium cobaltate coated with barium titanate is used as the positive electrode active material, the coating amount is 5wt.%, tantalum-doped lithium lanthanum zirconate is used as the solid electrolyte, and metal lithium is used as the negative electrode material. Solid lithium-ion battery, the specific steps are as follows:

[0063] (1) surface-treating tantalum-doped lithium lanthanum zirconate to obtain a solid electrolyte with a clean surface;

[0064] (2) Lithium cobaltate, lithium borate, and indium tin oxide conductive additive (mass ratio 6:3:1) coated with barium titanate were respectively dissolved in a solvent to prepare a positive electrode layer slurry, in which ethyl cellulose was used as a binder agent, the solvent is butyl carbitol, and the solid phase content ratio is 48wt.%.

[0065] (3) Coating and printing the positive electrode layer slurry on the surface of the solid electrolyte, and the...

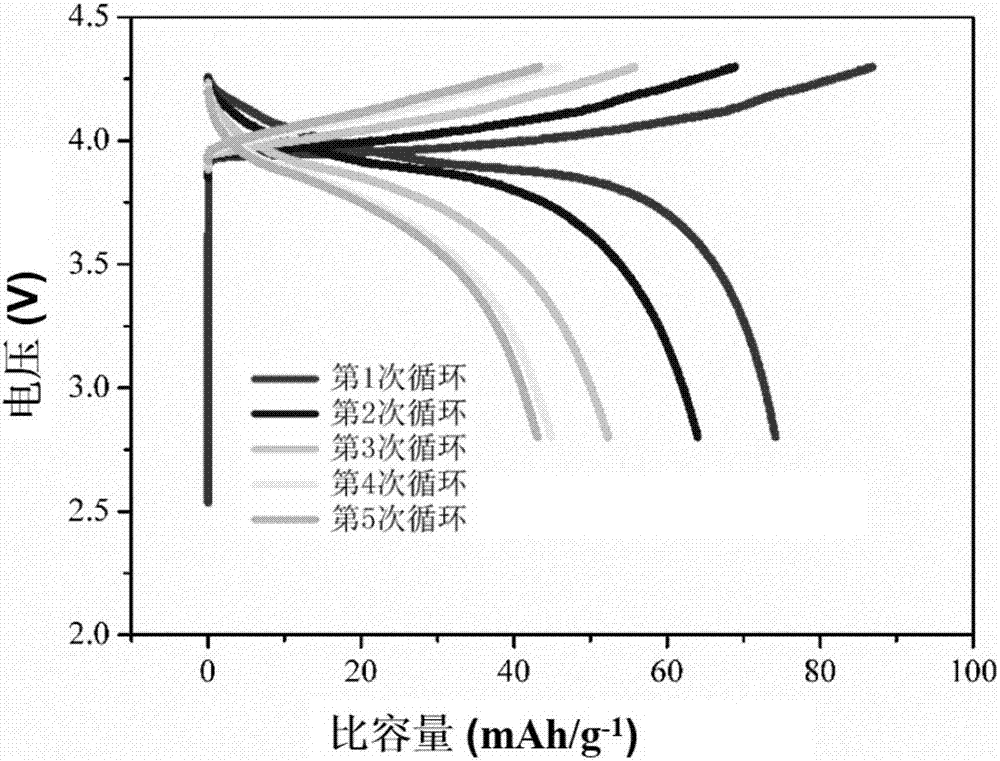

Embodiment 2

[0070] Using the method of the embodiment of the present invention, pure lithium cobaltate is used as the positive electrode active material, tantalum-doped lithium lanthanum zirconate is used as the solid electrolyte, and metal lithium is used as the negative electrode material to assemble a solid lithium ion battery. The specific steps are as follows:

[0071] (1) surface-treating tantalum-doped lithium lanthanum zirconate to obtain a solid electrolyte with a clean surface;

[0072] (2) Lithium cobaltate positive electrode active material, lithium borate, indium tin oxide conductive additive, and lithium fluoride (mass ratio 5:3:1:1) were respectively dissolved in a solvent to prepare positive electrode layer slurry, wherein ethyl cellulose As a binder, the solvent is butyl carbitol, and the solid phase content ratio is 48wt.%.

[0073] (3) Coating and printing the positive electrode layer slurry on the surface of the solid electrolyte, and then heat-treating at 700 degrees;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com