Preparation method of two-dimensional tungsten sulfide thin film material

A thin film material, tungsten sulfide technology, applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problem of high preparation temperature and achieve the effect of reducing the reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

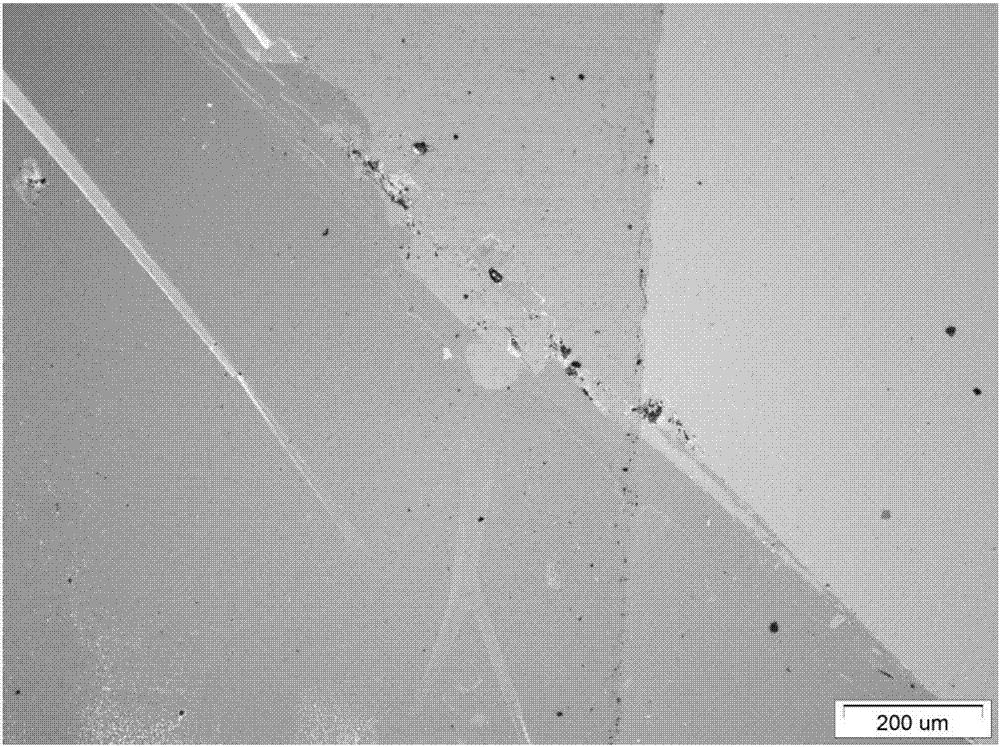

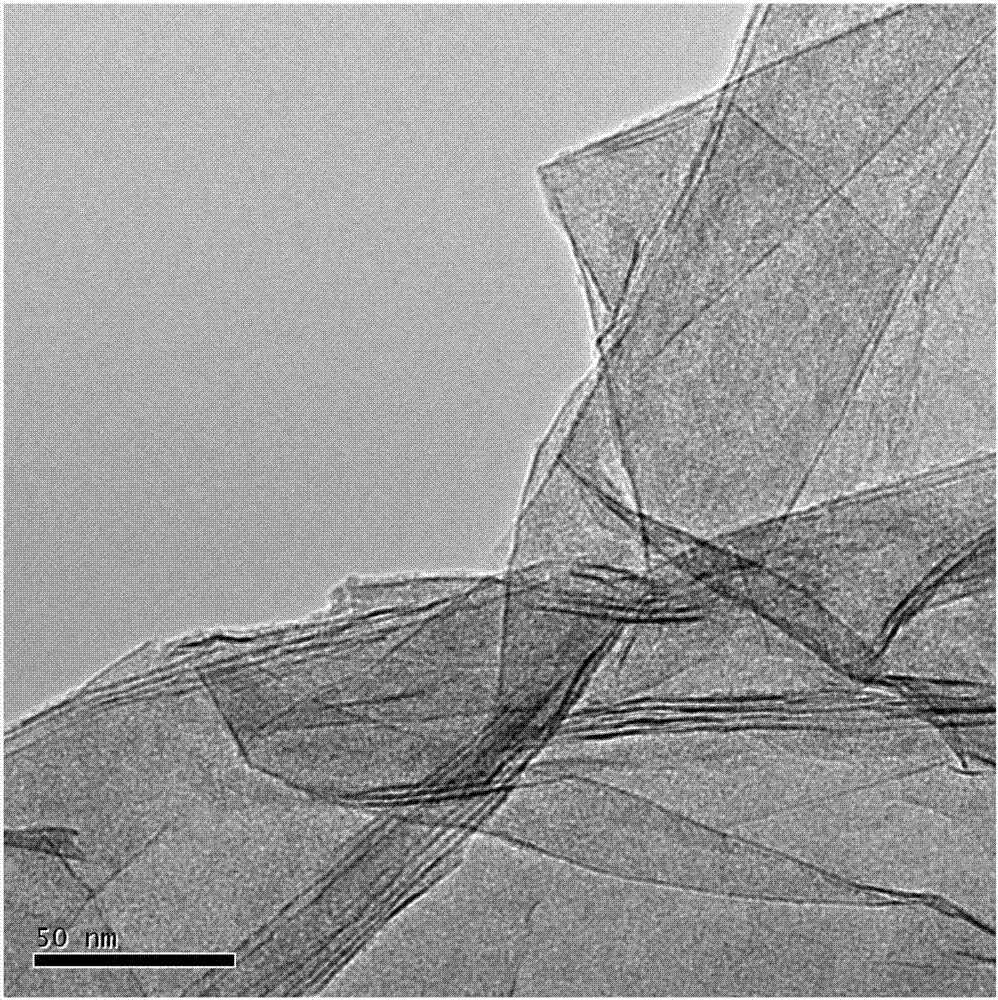

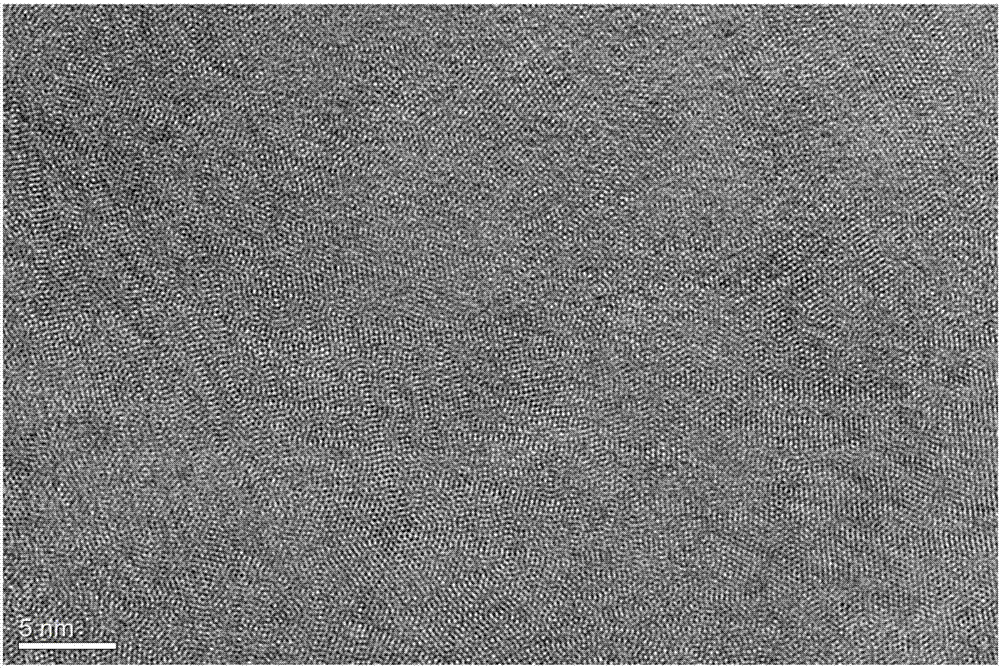

[0025] A kind of preparation method of two-dimensional tungsten sulfide film material of the present invention comprises the following process:

[0026] (1) Using a dual temperature field slide rail plasma PECVD system, a certain amount of argon gas is introduced into the quartz tube to remove the air; finally, a certain size of processed SiO 2 The / Si substrate is placed directly above the ship-shaped container with a certain mass of tungsten hexacarbonyl powder, and the container with a certain mass of sulfur powder is placed in the previous temperature zone of the tube furnace, and then the porcelain with tungsten hexacarbonyl powder is placed The boat is placed in the last temperature zone of the tube furnace (the amount of sulfur powder is 500mg, the mass ratio of tungsten hexacarbonyl to sulfur powder is 1-3:100. The mass ratio of 1:100 can get double-layer tungsten disulfide, 3: 100 mass ratio can get three layers of tungsten disulfide). Continue to pass through 10min,...

Embodiment 1

[0029] (1) Vacuumize the tube furnace to 133.29Pa, pass in argon, and remove the air; 2 / Si substrate is placed above the boat-shaped container with tungsten hexacarbonyl powder, put the container with 500mg of sulfur powder in the first heating zone of the tube furnace, and then put the porcelain boat with 5mg of tungsten hexacarbonyl on the tube The second heating zone of the furnace. Continue to pass through 10min, 10 ~ 20sccm of argon.

[0030] (2) The tube furnace was evacuated to 133.29Pa, the power of the plasma generator was set to 100W, and 10 sccm of hydrogen gas was introduced to remove the oxygen in the system. Raise the temperature of the first heating zone to 160°C, and the temperature of the second heating zone to 200°C; keep the two heating zones at the same time during the heating process, and raise the temperature to the corresponding temperature, and the heating time is 20 minutes; complete the heating in both heating zones Finally, change to 10sccm argon,...

Embodiment 2

[0033] (1) Vacuumize the tube furnace to 133.29Pa, pass in argon, and remove the air. After processing SiO 2 / Si substrate is placed above the boat-shaped container with tungsten hexacarbonyl powder, put the container with 500mg of sulfur powder in the first heating zone of the tube furnace, and then put the porcelain boat with 10mg of tungsten hexacarbonyl on the tube The second heating zone of the furnace. Continue to pass through 10min, 10 ~ 20sccm of argon.

[0034] (2) Vacuumize the tube furnace to 133.29Pa, set the power of the plasma generator to 250W, and feed 10 sccm of hydrogen to remove the oxygen in the system. Raise the temperature of the first heating zone to 160°C, and the temperature of the second heating zone to 200°C (keep the two heating zones at the same time during the heating process, and raise the temperature to the corresponding temperature, and the heating time is 20 minutes). After both heating zones have been heated up, switch to 10 sccm argon and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com