Preparation method for multi-layer core-shell structural carbon@nickel cobaltate@ferroferric oxide composite material

A technology of multi-layer core-shell structure and composite material is applied in the field of preparation of multi-layer core-shell structure carbon@nickel cobaltate@iron tetroxide composite material, achieving the effects of wide source, excellent performance and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

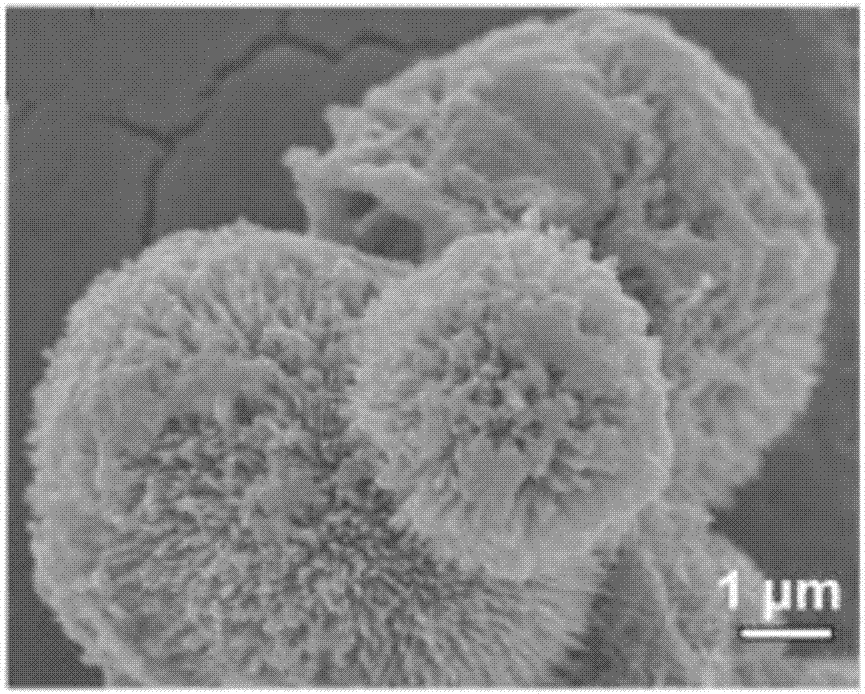

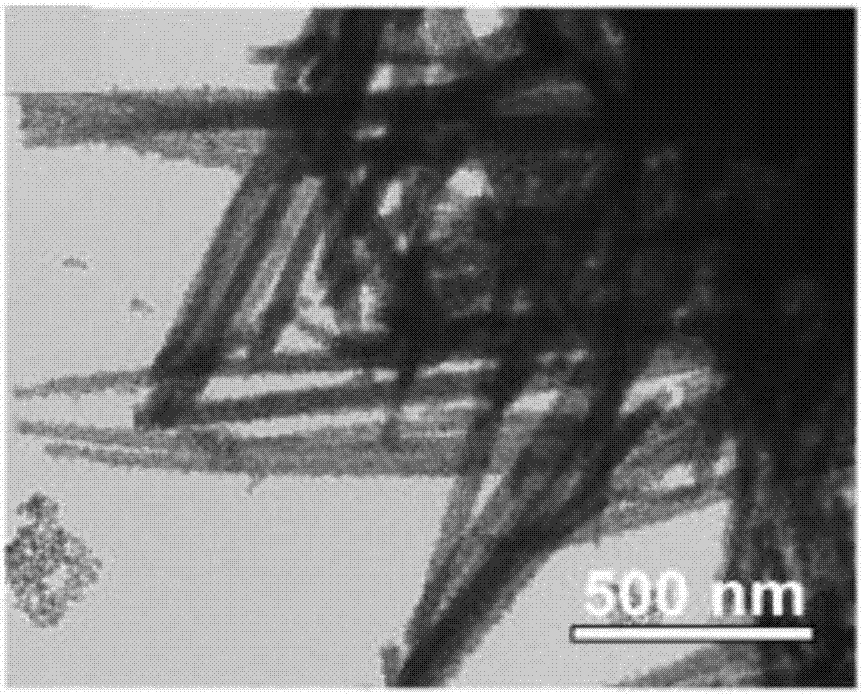

[0022] In this embodiment, nickel cobaltate, ferric oxide and carbon spheres are combined, and the specific preparation process is as follows:

[0023] (1) First weigh 0.0100g of glucose, 0.1164g of nickel nitrate, 0.2320g of cobalt nitrate and 0.2882g of urea with an electronic balance, then measure 50ml of deionized water with a graduated cylinder, put it in a 100ml beaker and mix , stirred magnetically at room temperature for 30 minutes to obtain a mixed solution, then transferred the mixed solution to a 100ml reactor, and reacted for 4.5 hours at 180°C. After the reaction, the obtained lavender product was slowly cooled to room temperature, and then the lavender product was Wash with deionized water for 5 to 8 times and freeze-dry to obtain the precursor of carbon@nickel cobaltate; then sinter the precursor of carbon@nickel cobaltate in a nitrogen atmosphere at 350°C for 5h, and wait until the temperature drops to about 80°C Take the sample out, cool it to room temperature...

Embodiment 2

[0028] In this example, manganese oxide is used instead of carbon spheres to prepare manganese oxide@nickel cobaltate@ferric oxide. The specific preparation process is as follows:

[0029] (1) Preparation of manganese oxide@nickel cobaltate: first weigh 0.1-0.2g of manganese dioxide nanorods, 0.30-0.70g of nickel nitrate, 1.00-1.30g of cobalt nitrate and 1.10-1.60g with an electronic balance urea, then measure 50-70ml of deionized water with a graduated cylinder, mix manganese oxide, nickel nitrate, cobalt nitrate, urea and deionized water in a 100ml beaker, and stir magnetically at room temperature for 30-60min to obtain a mixed solution. Then transfer the mixed solution to a 100ml reaction kettle, react at 150-200°C for 3-6 hours to obtain the product, and slowly cool it to room temperature, then wash the lavender product with deionized water for 5-8 times and freeze-dry to obtain Precursor of manganese oxide@nickel cobaltate; then sinter the obtained precursor of manganese ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com