Isobaric ammonia preparation technology taking gaseous hydrocarbon after autothermal reforming as raw material

A technology for autothermal reforming and gaseous hydrocarbons, which is applied in the field of synthetic ammonia, can solve the problems of low ammonia concentration at the outlet, large equipment investment, complicated operation, etc., and achieves the effects of high yield, reduced investment and operating cost, and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

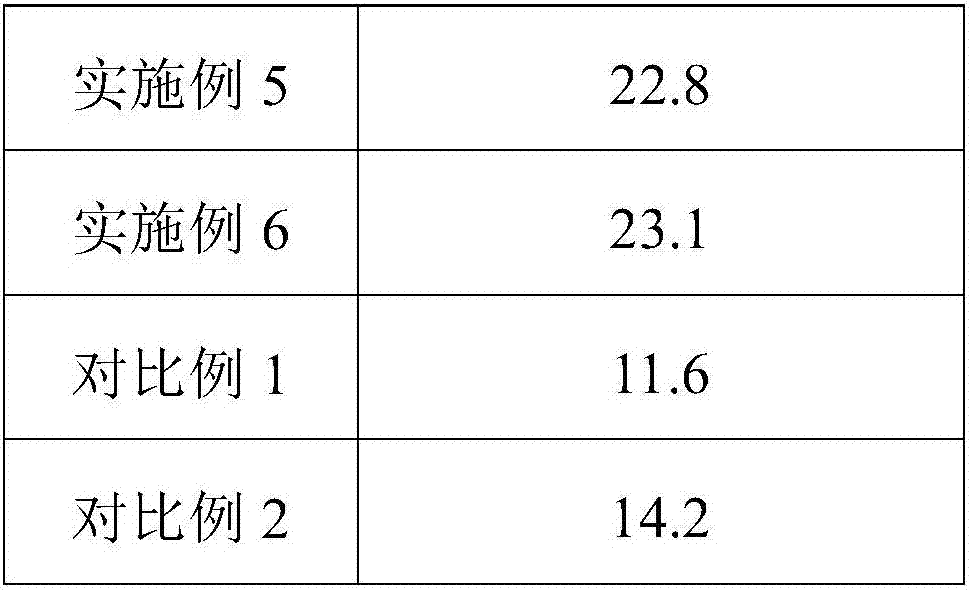

Examples

Embodiment 1

[0043] This embodiment provides a method for preparing the second ruthenium-based catalyst, comprising the steps of:

[0044] (1) Dissolve 20g of urea in 100g of water to form a nitrogen-containing solution, load the nitrogen-containing solution on magnesium-aluminum hydrotalcite with a magnesium-aluminum molar ratio of 0.6, heat and dry at 100°C, and Roasting in a nitrogen atmosphere at 190°C for 2 hours to obtain nitrogen-doped magnesium aluminum hydrotalcite, the doping amount of nitrogen element by mass is 5.5% of the mass of magnesium aluminum hydrotalcite;

[0045] (2) The above-mentioned nitrogen-doped magnesium aluminum hydrotalcite was heated to 630°C at a rate of 15°C / min and kept roasted for 1h, and then heated to 700°C at a rate of 3°C / min and kept roasted for 0.75h, and the roasted product It is the catalyst carrier, which contains 30v% spinel phase;

[0046] (3) Heating potassium fluorotantalate and sulfuric acid to above 400°C, and then diluting with water to u...

Embodiment 2

[0050] This embodiment provides a method for preparing the second ruthenium-based catalyst, comprising the steps of:

[0051] (1) Dissolve 15ml of ammonia water in 90ml of water to form a nitrogen-containing solution, and load the nitrogen-containing solution on magnesium-aluminum hydrotalcite with a magnesium-aluminum molar ratio of 1.7 by an equal-volume impregnation method, heat and dry at 80°C, and Roasting in an ammonia atmosphere at 200°C for 0.5h to obtain nitrogen-doped magnesium aluminum hydrotalcite, the doping amount of nitrogen element by mass is 8% of the mass of magnesium aluminum hydrotalcite;

[0052] (2) The above-mentioned nitrogen-doped magnesium aluminum hydrotalcite was heated to 600°C at a rate of 10°C / min and kept roasted for 3h, and then heated to 710°C at a rate of 5°C / min and kept roasted for 0.5h, and the roasted product It is the catalyst carrier, which contains 45v% spinel phase, and the pore radius distribution is in the range of 5-21nm;

[0053]...

Embodiment 3

[0057] This embodiment provides a method for preparing the second ruthenium-based catalyst, comprising the steps of:

[0058] (1) 12ml of hydrazine hydrate was dissolved in 100ml of water to form a nitrogenous solution, and the nitrogenous solution was loaded on magnesium-aluminum hydrotalcite with a magnesium-aluminum molar ratio of 2.5 by an equal-volume impregnation method, heated and dried at 90°C, and Roasting in an ammonia atmosphere at 200° C. for 1 h to obtain nitrogen-doped magnesium aluminum hydrotalcite, the doping amount of nitrogen element by mass is 10% of the mass of magnesium aluminum hydrotalcite;

[0059] (2) The above-mentioned nitrogen-doped magnesium aluminum hydrotalcite was heated to 650°C at a rate of 5°C / min and kept roasted for 2h, and then heated to 720°C at a rate of 1°C / min and kept roasted for 0.5h, and the roasted product It is the catalyst carrier, which contains 37v% spinel phase;

[0060] (3) Heating potassium fluorotantalate and sulfuric aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com