Bismuth ferrite-based dielectric film for high-density energy storage and preparation method and application thereof

A technology based on bismuth ferrite and bismuth ferrite, applied in the direction of fixed capacitor dielectric, circuit, capacitor, etc., can solve the problems of human health and environmental hazards, difficult to handle, etc., achieve high breakdown field strength, strong high voltage resistance, The effect of strong ferroelectricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

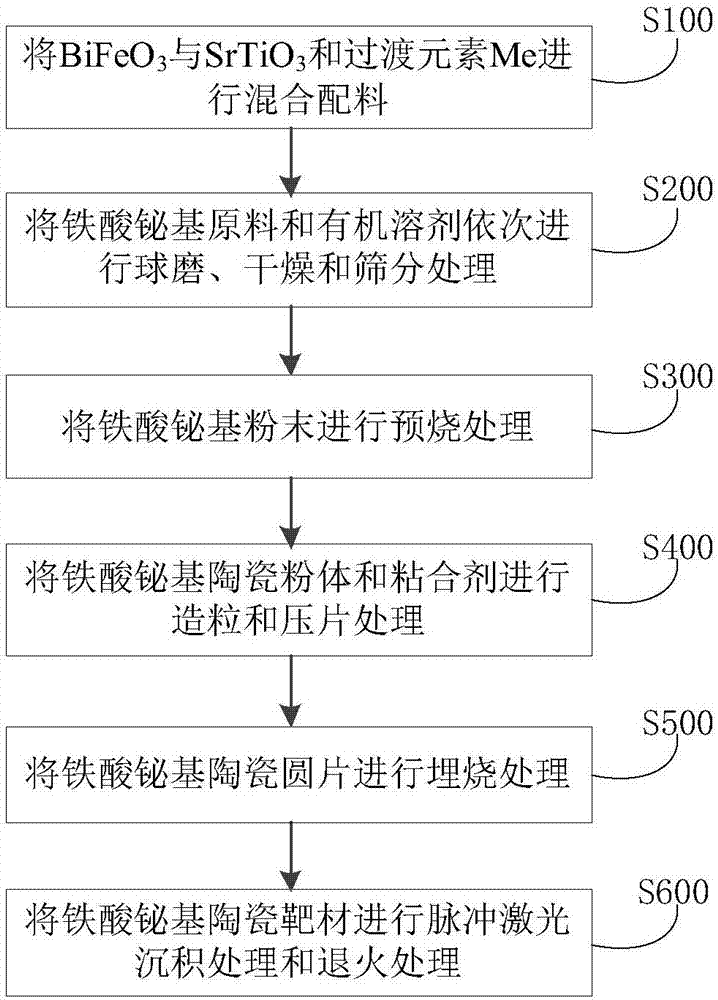

[0073] The method for preparing a bismuth ferrite-based dielectric thin film for high-density energy storage according to an embodiment of the present invention is performed by mixing BiFeO 3 with SrTiO 3 The bismuth ferrite-based raw material is prepared by mixing with the transition element Me. The doping of the transition element can reduce the leakage conductance of the bismuth ferrite-based dielectric film; by pre-sintering the bismuth ferrite-based powder, a series of physical and chemical reactions will occur. , can improve the composition and structure of bismuth ferrite-based powder, and improve the performance of bismuth ferrite-based powder; the bismuth ferrite-based dielectric film obtained by this method for high-density energy storage is characterized by lead-free environmental protection, high voltage resistance Strong ability and excellent energy storage performance. Bismuth ferrite has strong ferroelectricity and its spontaneous polarization can reach 100 μC / ...

Embodiment 1

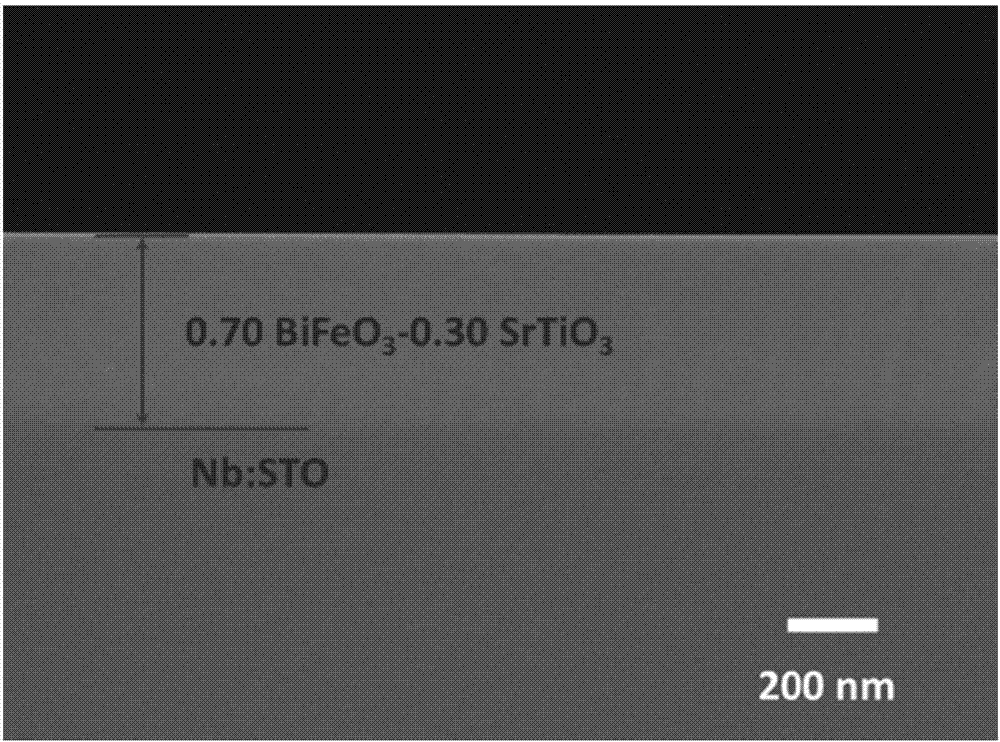

[0078] The raw material Fe 2 O 3 , SrCO 3 , Bi 2 O 3 , TiO 2 and MnO 2 Press (1-x)Bi 1.1 Fe 0.995 Mn 0.005 O 3 -xSrTiO 3(x=0.30) chemical formula for ingredients, ball milling with absolute ethanol for 12 hours, drying and sieving, and pre-sintering the obtained powder at 760 degrees Celsius for 4 hours to obtain bismuth ferrite-based ceramic powder. PVA solution with a concentration of 5% (mass percentage) was added to the bismuth ferrite-based ceramic powder for granulation, and pressed into a bismuth ferrite-based ceramic disc with a diameter of about 1 inch and a thickness of about 5mm under a 12MPa tablet press. After heat preservation and removal of PVA, the bismuth ferrite-based ceramic disc was sealed and buried for 40 minutes at 1100 degrees Celsius to obtain a bismuth ferrite-based ceramic target.

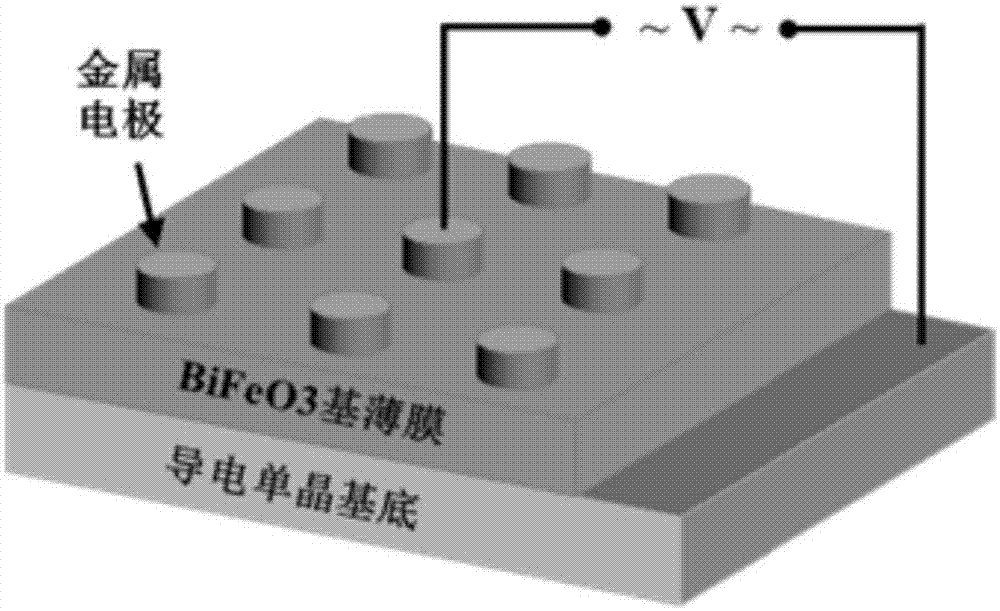

[0079] Using pulsed laser deposition technology, a bismuth ferrite-based ceramic target is bombarded with a laser, so that its components diffuse into a niobiu...

Embodiment 2

[0082] The raw material Fe 2 O 3 , SrCO 3 , Bi 2 O 3 , TiO 2 and MnO 2 Press (1-x)Bi 1.1 Fe 0.995 Mn 0.005 O 3 -xSrTiO 3 (x=0.45) chemical formula for ingredients, ball-milling with absolute ethanol for 12 hours, drying and sieving, and pre-sintering the obtained powder at 760 degrees Celsius for 4 hours to obtain bismuth ferrite-based ceramic powder. PVA solution with a concentration of 5% (mass percentage) was added to the bismuth ferrite-based ceramic powder for granulation, and pressed into a bismuth ferrite-based ceramic disc with a diameter of about 1 inch and a thickness of about 5mm under a 12MPa tablet press. After heat preservation and removal of PVA, the bismuth ferrite-based ceramic disc was sealed and buried for 40 minutes at 1100 degrees Celsius to obtain a bismuth ferrite-based ceramic target.

[0083] Using pulsed laser deposition technology, a bismuth ferrite-based ceramic target is bombarded with a laser, so that its components diffuse into a niobi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Breakdown field strength | aaaaa | aaaaa |

| Energy storage density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com