Yttrium-stabilized zirconia slurry, preparation method thereof and preparation method of yttrium-stabilized zirconia green body

A technology of yttrium-stabilized zirconia and slurry, applied in the direction of pressing rollers, etc., can solve the problems of low solid content, high organic content, and increasing the complexity of the molding process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

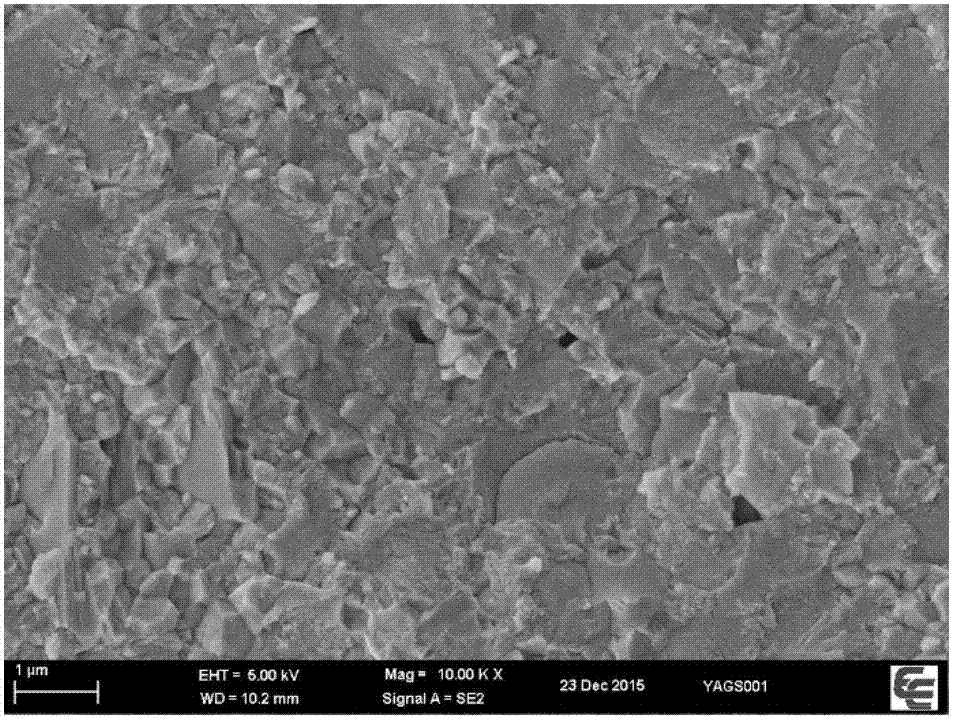

Image

Examples

preparation example Construction

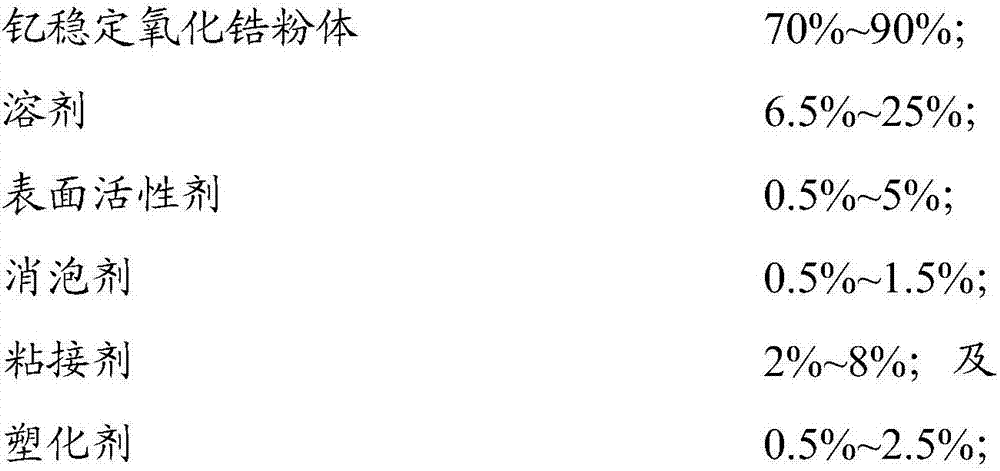

[0033] The preparation method of above-mentioned yttrium stabilized zirconia slurry comprises the following steps:

[0034] Step S110 , mixing the yttrium-stabilized zirconia powder, solvent, surfactant and defoamer, and ball milling for 6 hours to 24 hours to obtain a premix.

[0035] In one of the embodiments, zirconium balls are added for ball milling. Further, the mass ratio of zirconium balls to yttrium-stabilized zirconia powder is 2:1-5:1.

[0036] Step S120 , adding plasticizer and binder to the premix and continuing ball milling for 8 hours to 24 hours to obtain yttrium stabilized zirconia slurry.

[0037] In one embodiment, the pellets are separated after ball milling.

[0038] Step S130, degassing the yttrium-stabilized zirconia slurry for 30 minutes to 60 minutes in vacuum.

[0039] In one of the embodiments, vacuum defoaming is carried out under the condition of -0.06MPa~-0.09MPa.

[0040] The above-mentioned preparation method of the yttrium-stabilized zircon...

Embodiment 1

[0049](1) Slurry preparation: After mixing 70 parts of yttrium-stabilized zirconia powder, 18 parts of solvent, 1 part of castor oil, and 1 part of polydimethylsiloxane, add 140 parts of zirconium balls, and ball mill for 12 After one hour, add 8 parts of ethyl cellulose and 2 parts of polyethylene glycol 550, continue ball milling for 12 hours, obtain yttrium-stabilized zirconia slurry after ball separation, and place the yttrium-stabilized zirconia slurry at -0.06MPa Vacuum defoaming for 30 minutes, wherein the solvent includes 30 parts of absolute ethanol and 70 parts of water, and the molar ratio of zirconia to yttrium oxide in the yttrium-stabilized zirconia powder is 97:3.

[0050] (2) The distance between the control rollers is 0.25mm, the rotating speed is 140rpm, the drying temperature is 120°C, and the drying time is 60min, and the yttrium-stabilized zirconia slurry is rolled and dried to obtain a 0.2mm thick and pressed Solid body, and cut according to the size of 1...

Embodiment 2

[0052] (1) Slurry preparation: After mixing 75 parts of yttrium-stabilized zirconia powder, 13.5 parts of solvent, 0.75 parts of triethanolamine, and 0.75 parts of polyoxypropylene glyceryl ether, add 225 parts of zirconium balls and ball mill for 8 hours , add 8 parts of polyvinyl alcohol and 2 parts of DOP, continue ball milling for 16 hours, obtain yttrium-stabilized zirconia slurry after ball separation, and vacuum degas the yttrium-stabilized zirconia slurry for 30 minutes at -0.07MPa, wherein The solvent includes 15 parts of n-propyl acetate and 85 parts of water, and the molar ratio of zirconia to yttrium oxide in the yttrium-stabilized zirconia powder is 95:5.

[0053] (2) Control the distance between the roller shafts to be 0.35mm, the rotating speed to be 130rpm, the drying temperature to be 130°C, and the drying time to be 70min. Roll and dry the yttrium-stabilized zirconia slurry to obtain a 0.3mm thick and pressed Solid body, and cut according to the size of 140mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com