Device for preparing fertilizer by using excess sludge and agricultural and forestry waste

A technology for preparing agricultural and forestry wastes and fertilizers, which is applied in the field of solid waste resource utilization devices, can solve the problems of slow growth and reproduction of microorganisms, insufficient nutrients, limited humus, etc., and achieve shortened composting cycle, comprehensive nutrients, and low bacteria and virus content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

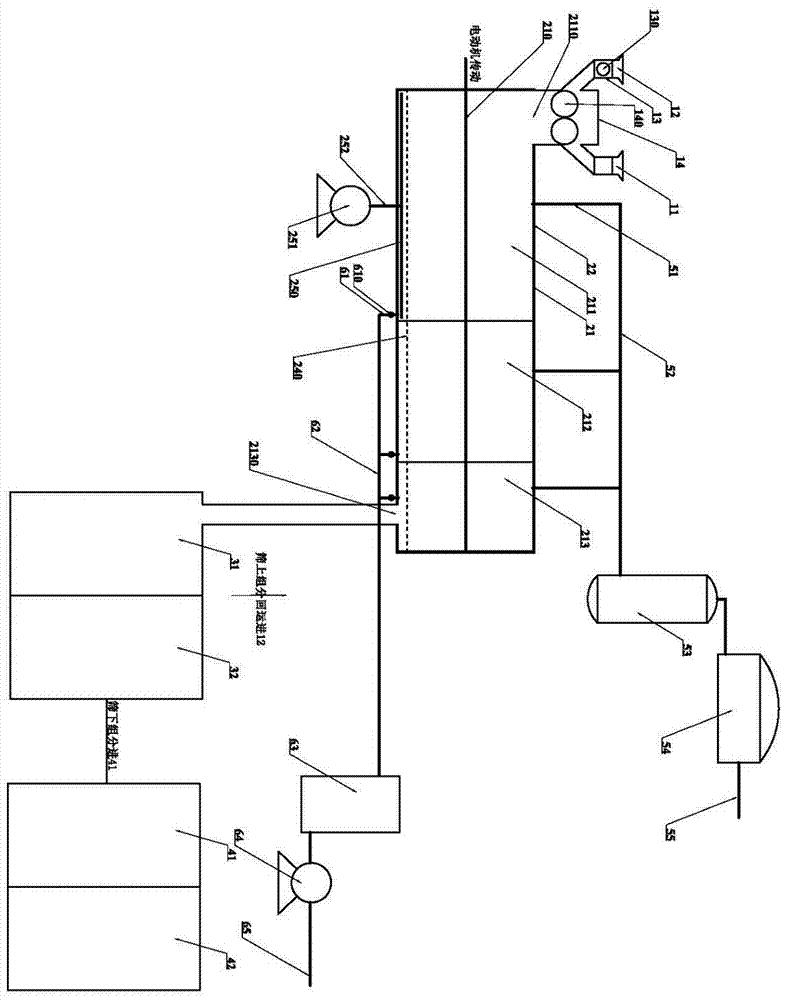

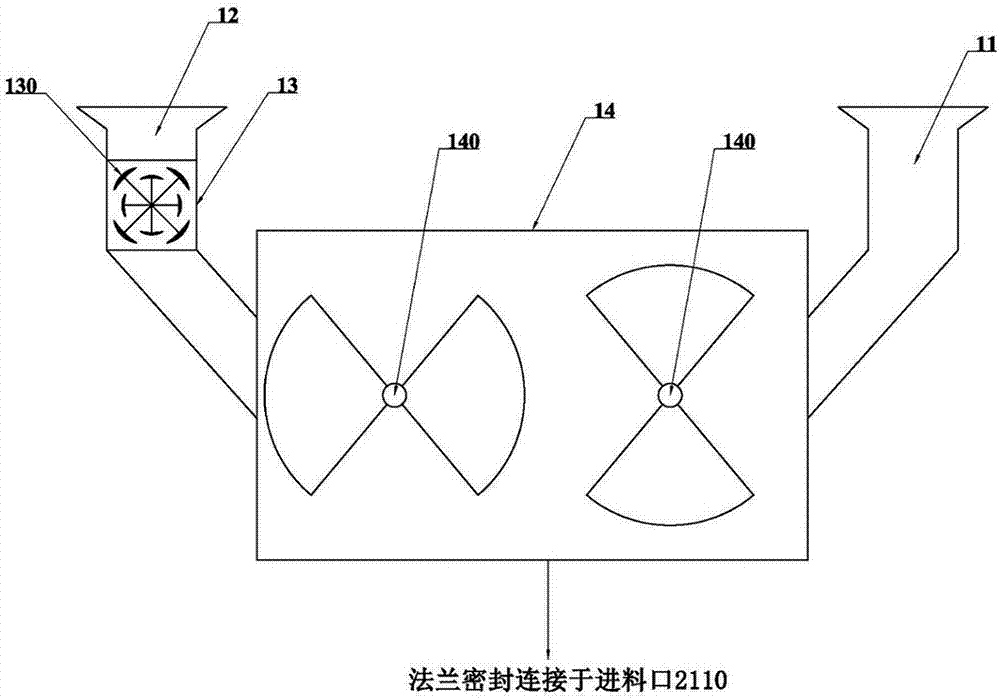

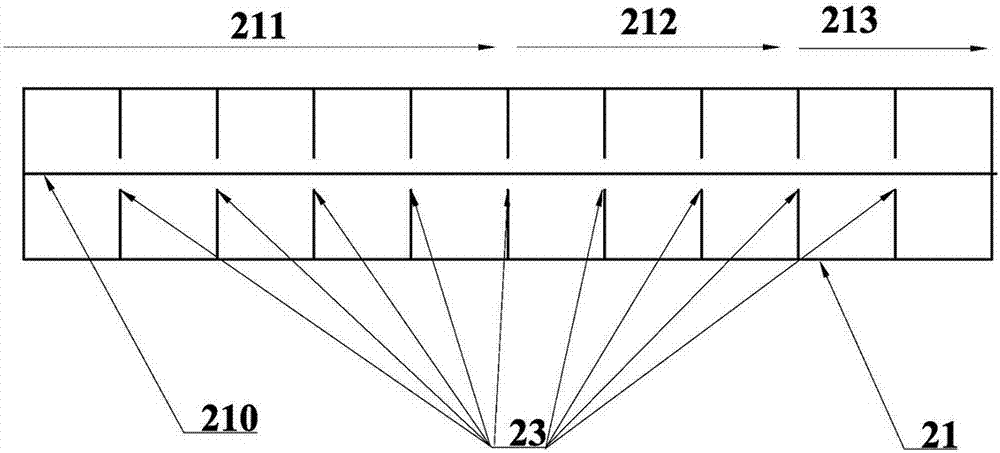

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Using the remaining workshop sludge of the urban sewage treatment plant in Hanzhong City and sawdust from a wood processing plant in Hanzhong City as raw materials, the moisture content of the remaining sludge was measured to be 85.32%, the pH value was 6.8, and the organic matter content was 72.52% (anhydrous sludge mass percentage), TN content is 10.28% (anhydrous sludge mass percentage), TP content is 0.54% (anhydrous sludge); the measured wood chip cellulose content is 68.18%, of which hemicellulose content is 7.46% . During the experiment, the organic fertilizer was prepared by adding the mass ratio of wood chips and residual sludge at 1:1. The experiment found that under the condition of air blast volume of 1.8L / (Kg·min), the aerobic fermentation time was 10 days, and the facultative fermentation time was 8d, the anaerobic fermentation time is 6d, the measured humus content of compost product is 63.44% (mass percentage of product dried at 105°C), TN con...

Embodiment 2

[0025] Example 2: Using the remaining workshop sludge of the urban sewage treatment plant in Hanzhong City and sawdust from a wood processing plant in Hanzhong City as raw materials, the moisture content of the remaining sludge was measured to be 87.55%, the pH value was 6.6, and the organic matter content was 75.10% (anhydrous sludge mass percentage), TN content is 11.32% (anhydrous sludge mass percentage), TP content is 0.69% (anhydrous sludge); the measured wood chip cellulose content is 71.53%, of which hemicellulose content is 8.56% . During the experiment, the organic fertilizer was prepared by adding the mass ratio of wood chips and residual sludge at 1:1. The experiment found that under the condition of air blast volume of 1.8L / (Kg·min), the aerobic fermentation time was 10 days, and the facultative fermentation time was 8d, the anaerobic fermentation time was 6d, and the measured humus content of compost products was 62.26% (mass percentage of products dried at 105°C)...

Embodiment 3

[0026] Example 3: Using the remaining workshop sludge of the urban sewage treatment plant in Hanzhong City and sawdust from a wood processing plant in Hanzhong City as raw materials, the moisture content of the remaining sludge was measured to be 87.55%, the pH value was 6.6, and the organic matter content was 75.10% (anhydrous sludge mass percentage), TN content is 11.32% (anhydrous sludge mass percentage), TP content is 0.69% (anhydrous sludge); the measured wood chip cellulose content is 71.53%, of which hemicellulose content is 8.56% . During the experiment, the organic fertilizer was prepared by adding the mass ratio of sawdust and residual sludge at 1:1. The experiment found that under the condition of air blast volume of 1.8L / (Kg min), the aerobic fermentation time was 8 days, and the facultative fermentation time was 8d, the anaerobic fermentation time is 8d, the measured humus content of the compost product is 68.25% (mass percentage of product dried at 105°C), TN con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com