Functional soil conditioner and preparation method thereof

A soil conditioner and a functional technology, applied in the field of functional soil conditioner and its preparation, can solve the problems of safety restricting the development of agricultural product quality, imbalance of beneficial microbial flora, unreasonable farming, crop rotation, etc., and achieve a good removal effect , the effect of improving physical properties and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

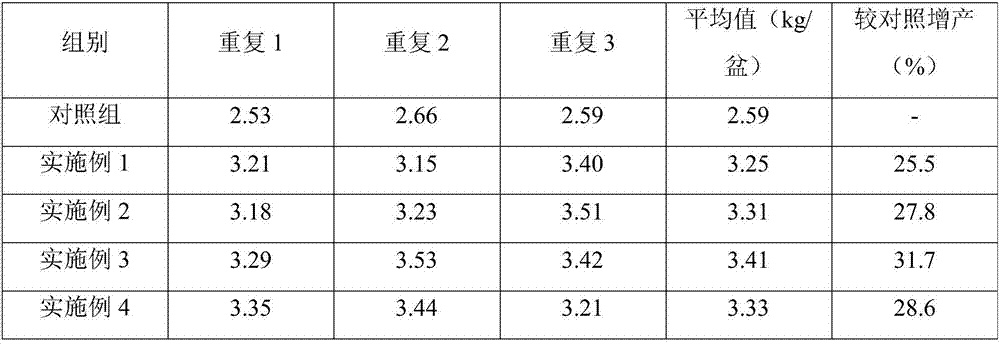

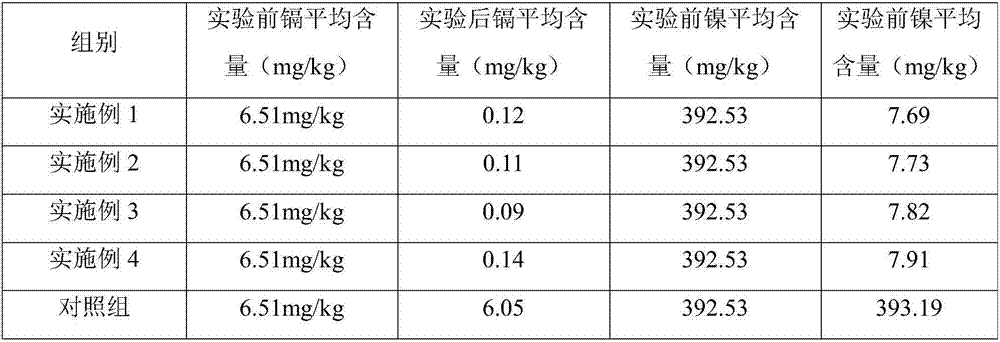

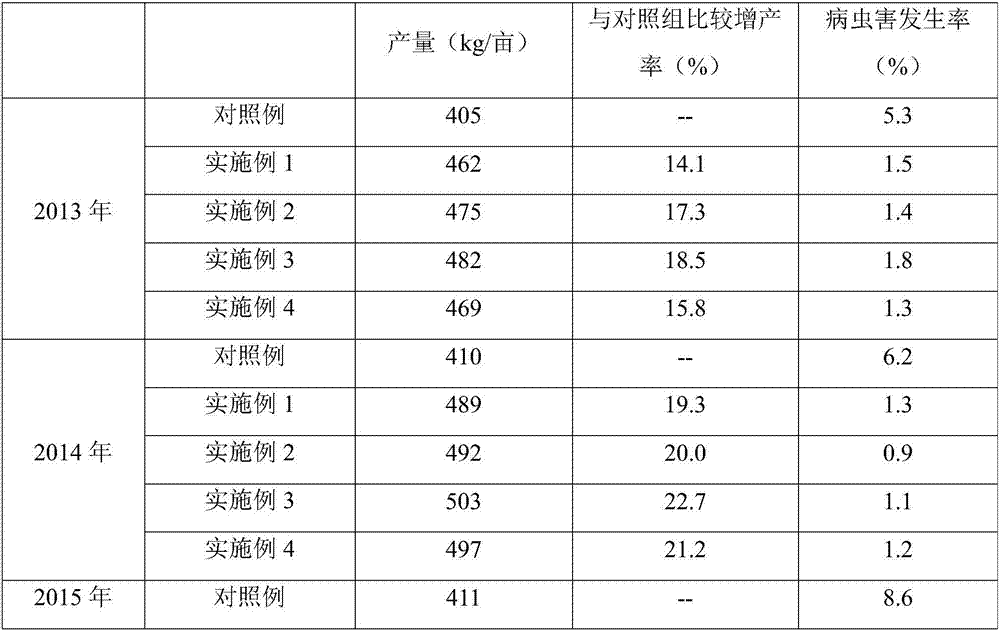

Examples

Embodiment 1

[0025] A functional soil conditioner, the raw material composition is: 20 parts of hazelnut meal, 1 part of γ-polyglutamic acid, 3 parts of compound microbial bacterial agent, 10 parts of traditional Chinese medicine residue, 60 parts of fly ash, 0.5 part of silanized modified zeolite , 1 part of zinc sulfate. The fly ash is finely ground fly ash with a specific surface area ≥ 400m 2 / kg, loss on ignition ≤7%.

[0026] The hazelnut meal is prepared by the following method: add 3-8% by weight nutrient solution and 2-3% by weight to the hazelnut meal whose oil content after extracting the oil from the hazelnut kernel is 3-5% After fermenting at 55-65°C for 12-18 hours in a fermentation room, dry it at 35°C until the water content is ≤5%, and then crush it through a 150-mesh sieve. The weight percent composition is: 15% of soybean milk, 3% of vitamin C, 3% of humic acid, 5% of magnesium sulfate, 10% of glucose, the rest of water, and the pH is 5.5.

[0027] The composite micro...

Embodiment 2

[0036]A functional soil conditioner, the raw material composition is: 25 parts of hazelnut meal, 1.5 parts of γ-polyglutamic acid, 4 parts of compound microbial bacterial agent, 15 parts of traditional Chinese medicine residue, 70 parts of fly ash, 0.6 parts of silanized modified zeolite parts, 1.1 parts of zinc sulfate. The fly ash is finely ground fly ash with a specific surface area ≥ 400m 2 / kg, loss on ignition ≤7%.

[0037] The hazelnut meal is prepared by the following method: add 3-8% by weight nutrient solution and 2-3% by weight to the hazelnut meal whose oil content after extracting the oil from the hazelnut kernel is 3-5% After fermenting at 55-65°C for 12-18 hours in a fermentation room, dry it at 35°C until the water content is ≤5%, and then crush it through a 150-mesh sieve. The weight percent composition is: 15% of soybean milk, 3% of vitamin C, 3% of humic acid, 5% of magnesium sulfate, 10% of glucose, the rest of water, and the pH is 5.5.

[0038] The comp...

Embodiment 3

[0047] A functional soil conditioner, the raw material composition is: 30 parts of hazelnut meal, 1.6 parts of γ-polyglutamic acid, 4 parts of compound microbial bacterial agent, 20 parts of traditional Chinese medicine residue, 75 parts of fly ash, 0.7 parts of silanized modified zeolite Parts, 1.3 parts of zinc sulfate. The fly ash is finely ground fly ash with a specific surface area ≥ 400m 2 / kg, loss on ignition ≤7%.

[0048] The hazelnut meal is prepared by the following method: add 3-8% by weight nutrient solution and 2-3% by weight to the hazelnut meal whose oil content after extracting the oil from the hazelnut kernel is 3-5% After fermenting at 55-65°C for 12-18 hours in a fermentation room, dry it at 35°C until the water content is ≤5%, and then crush it through a 150-mesh sieve. The weight percent composition is: 15% of soybean milk, 3% of vitamin C, 3% of humic acid, 5% of magnesium sulfate, 10% of glucose, the rest of water, and the pH is 5.5.

[0049] The com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com