Soil heavy mental eluant, preparation method, application method and waste liquid treatment method

A technology of heavy metals and leaching agents, applied in the field of soil treatment, can solve the problems of mutual consumption, complex use process, easy to cause pollution, and limit practical application, so as to achieve no secondary pollution, good washing effect, and increased practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A detergent for soil polluted by heavy metals, the active ingredient of which is mainly alkaline soluble humic acid, the specific preparation steps are as follows:

[0030] Step (1), take Xinjiang weathered coal and Shanxi lignite rich in humus, remove sundries, air-dry and grind, pass through a 2-mm sieve for subsequent use;

[0031] In step (2), the material obtained in step (1) is added to 0.1M KOH solution according to the mass volume ratio of 1:20, and the mixed coal slurry is kept under the condition of intermittent vibration for 6 hours to activate and extract humic acid .

[0032] In step (3), the mixture obtained in step (2) is allowed to stand for 2 hours, the extracted humic acid is separated from the solid residue by natural sedimentation, and then the upper humic acid liquid is extracted.

[0033] In step (4), the solid residue of step (3) is mixed with potassium hydroxide solution, and steps (2) and (3) are repeated 5 times in total. Mix the extracts eac...

Embodiment 2

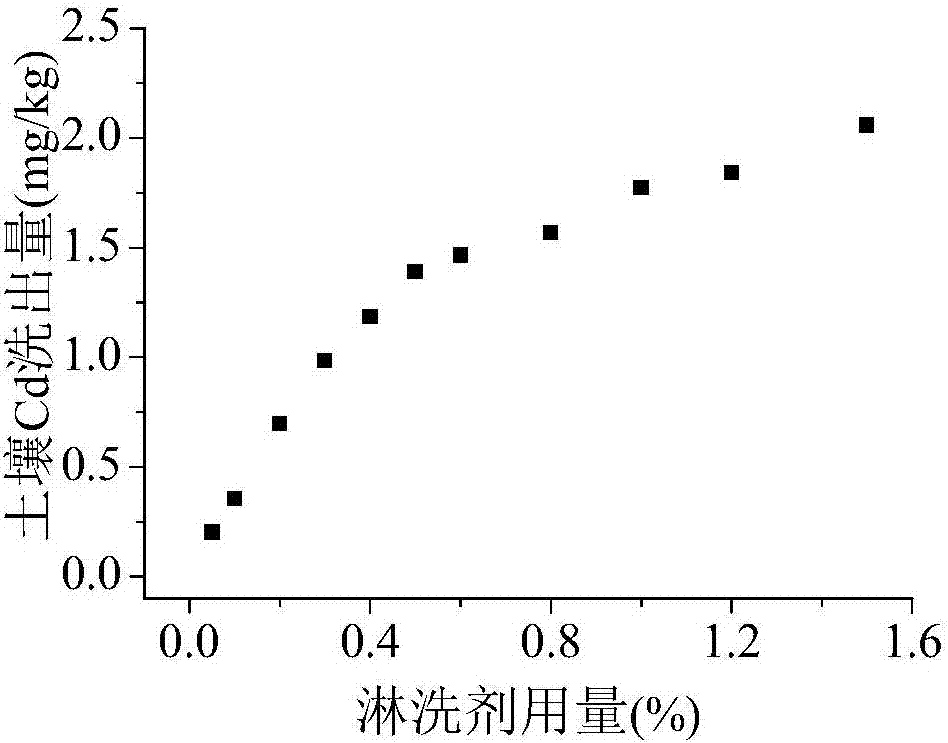

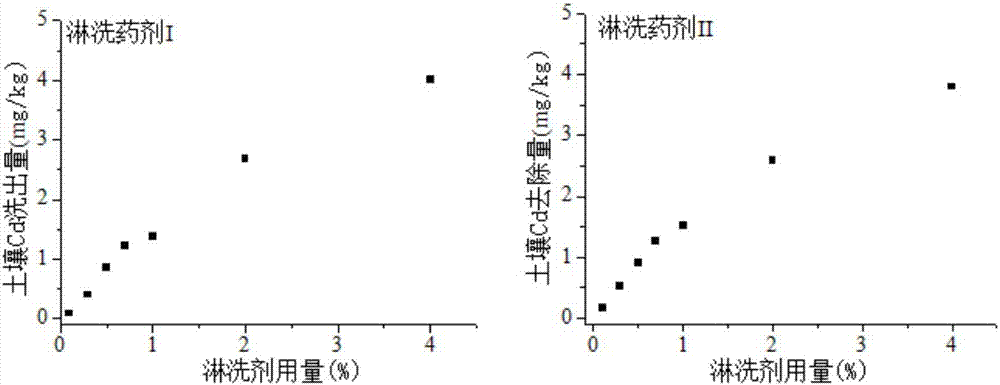

[0040] Washing effect of different leaching agents on heavy metal polluted soil

[0041] The contaminated soil samples came from farmland near a non-ferrous metal smelter in Hunan Province. The heavy metal Cd (6.57mg / kg) in the soil exceeded the standard, while other heavy metals did not exceed the standard, pH=6.16, organic carbon 1.88%. Take an appropriate amount of the soil, air-dry it, grind it finely, and pass it through a 2-mm sieve for later use. Using deionized water as a solvent, dissolve the rinsing agent of the present invention to prepare a rinsing solution, the concentrations are respectively 0.1, 0.3, 0.5, 0.7, 1.0, 2, 4% (mass concentration g / 100mL), and the pH of the solution is adjusted to 6.0 . Mix the heavy metal-contaminated soil and eluent thoroughly in a 15mL centrifuge tube at a solid-to-liquid ratio of 1:5 (g:mL), shake the sample at 3000r min for 12 hours -1 Centrifuge for 25 minutes, take the supernatant and filter it with a 0.45 μm aqueous polyeth...

Embodiment 3

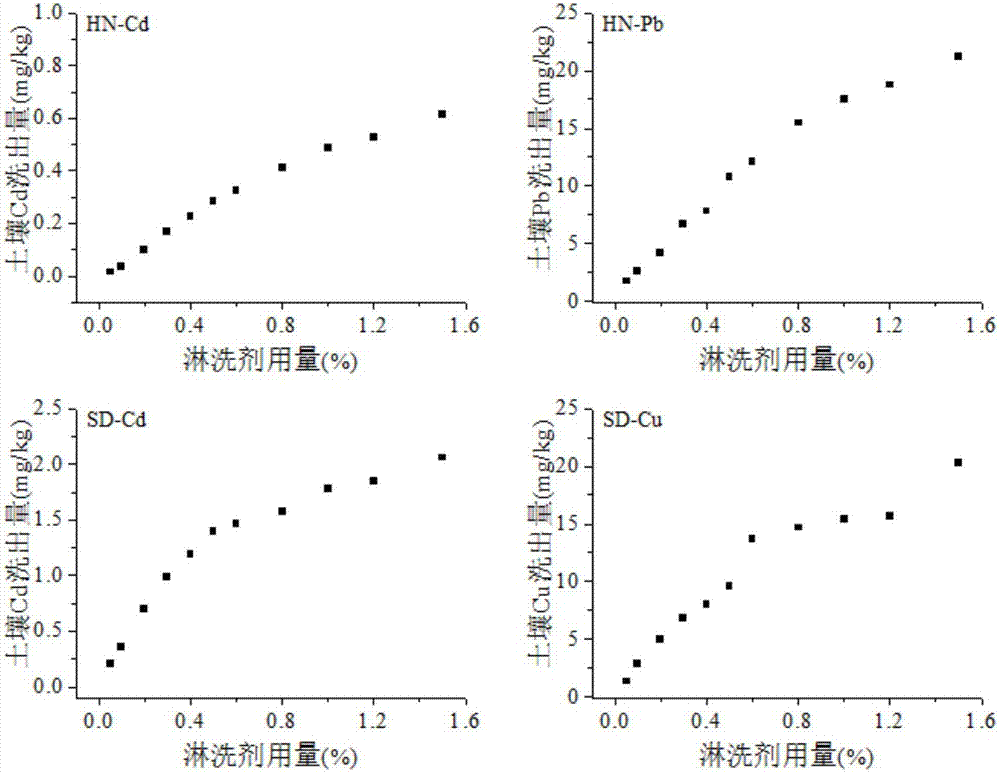

[0044] Determination of washing ability of leaching agent to heavy metals in different soils by batch balance method

[0045] Two contaminated soil samples were obtained from a farmland near a nonferrous metal smelter in Hunan Province and an orchard in Yantai City, Shandong Province, denoted as HN and SD, respectively. The soil properties and heavy metal concentrations of HN and SD are shown in Table 1.

[0046] Table 1

[0047]

[0048] Take an appropriate amount of soil, air-dry it, grind it finely, and pass it through a 2-mm sieve for later use. With deionized water as solvent, rinse agent I of the present invention is dissolved and formulated into 0.05, 0.1, 0.15, 0.2, 0.3, 0.4, 0.5, 0.6, 0.8, 1.0, 1.2, 1.5% (mass concentration g / 100mL) Wash solution, adjust its pH to 6.0. Mix the heavy metal-contaminated soil and washing liquid in a 1:5 (g:mL) well in a 15mL centrifuge tube, shake the sample at 3000r·min after shaking for 12 hours -1 Centrifuge for 15 minutes, tak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com