Method of preparing gate dielectric film of SiC-based MOS device

A technology of MOS devices and gate dielectrics, applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problem of low carrier mobility, reduce the interface state density, and improve the channel carrier mobility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

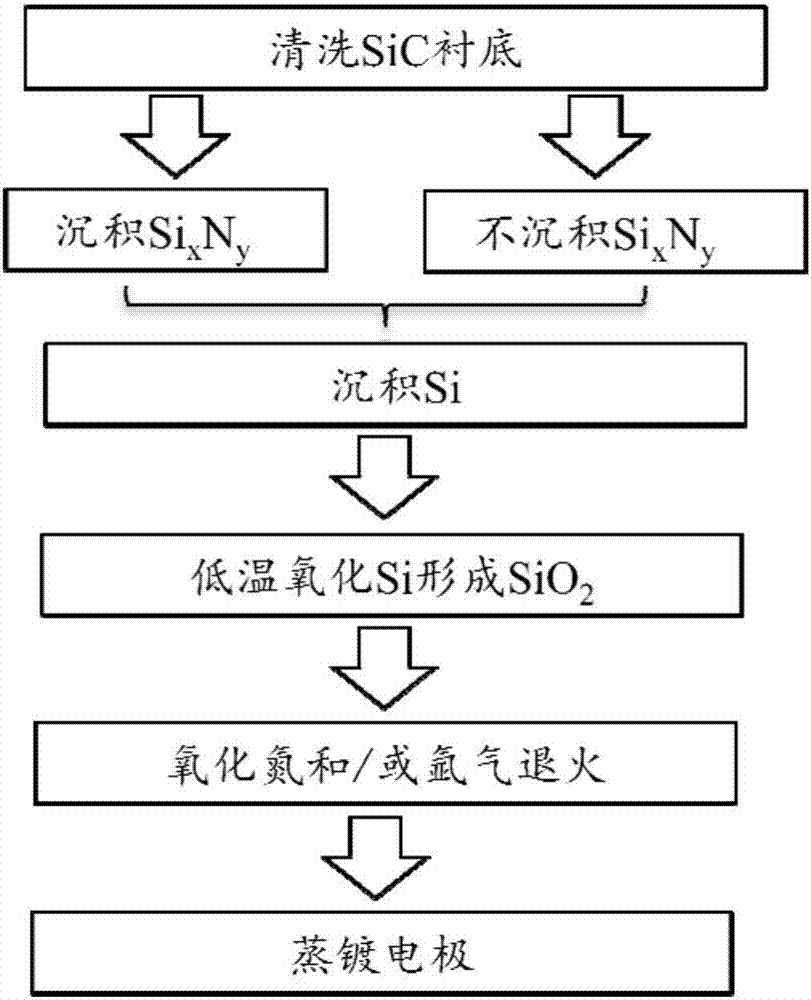

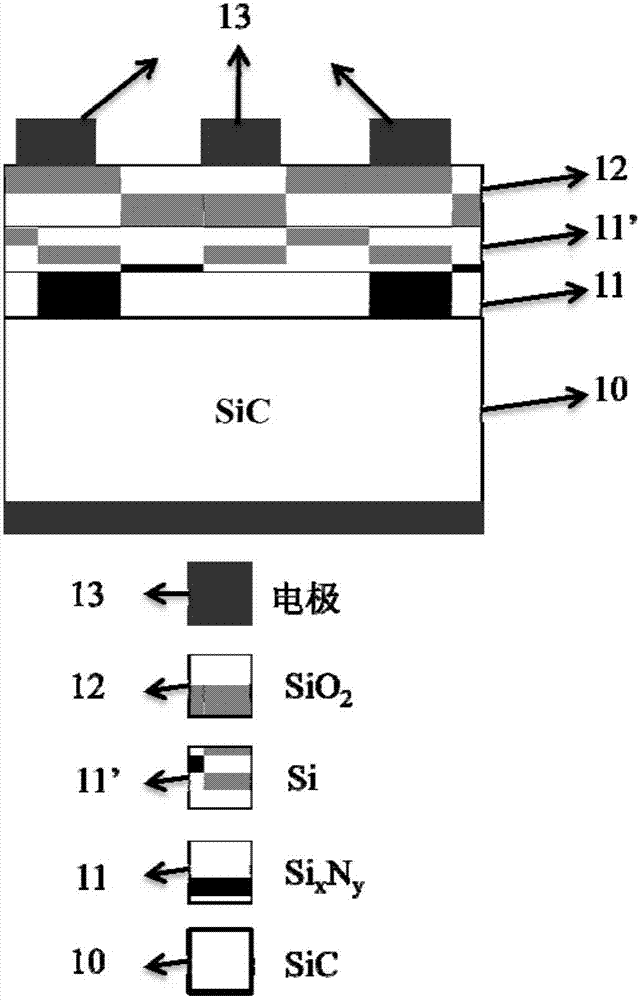

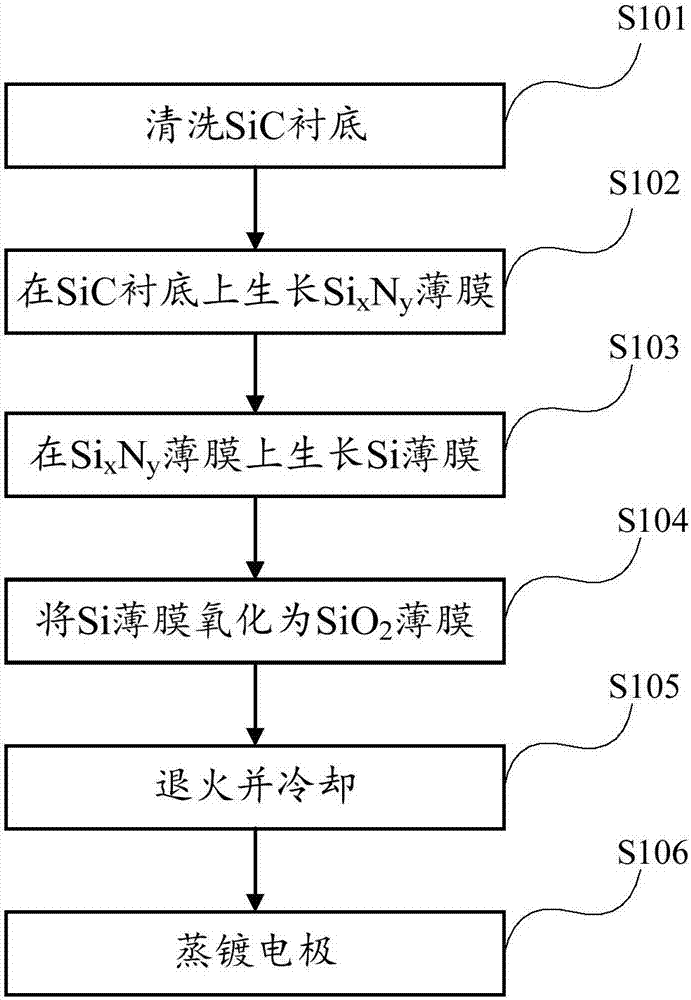

[0049] figure 2 It is a flow chart of the method for preparing a SiC-based MOS device gate dielectric film related to Embodiment 1. This embodiment involves Si x N y / SiO 2 gate dielectric layer.

[0050] First, step S101 is performed to clean the SiC substrate. In this embodiment, a 4H-SiC substrate sample is used, and a standard cleaning is performed on the 4H-SiC substrate sample.

[0051] a. Ultrasonic cleaning three times with toluene, acetone and ethanol in sequence, and then rinsed with deionized water.

[0052] b. Soak the rinsed substrate in diluted hydrofluoric acid (hydrogen fluoride: deionized water = 1:3 by volume) for 1 min.

[0053] c. Boil the substrate soaked in hydrofluoric acid in concentrated sulfuric acid for 10 minutes.

[0054] d. Boil the substrate boiled in concentrated sulfuric acid with No. 1 solution and No. 2 solution for 15 minutes, rinse it with deionized water, and dry it with nitrogen gas for use. The No. 1 liquid is a mixture of ammonia...

Embodiment 2

[0062] image 3 It is a flow chart of the method for preparing a SiC-based MOS device gate dielectric film related to the second embodiment, and this embodiment involves SiO 2 gate dielectric layer.

[0063] First, step S201 is performed to clean the SiC substrate. In this embodiment, a 4H-SiC substrate sample is used, and a standard cleaning is performed on the 4H-SiC substrate sample.

[0064] a. Ultrasonic cleaning three times with toluene, acetone and ethanol in sequence, and then rinsed with deionized water.

[0065] b. Soak the rinsed substrate in diluted hydrofluoric acid (hydrogen fluoride: deionized water = 1:3 by volume) for 1 min.

[0066] c. Boil the substrate soaked in hydrofluoric acid in concentrated sulfuric acid for 10 minutes.

[0067] d. Boil the substrate boiled in concentrated sulfuric acid with No. 1 solution and No. 2 solution for 15 minutes, rinse it with deionized water, and dry it with nitrogen gas for use. The No. 1 liquid is a mixture of ammoni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com