Preparation method of composite vegetable protein fertilizer

A plant protein and fertilizer technology, which is applied in the preparation of organic fertilizers, fertilizers made from biological waste, and the molding or processing of animal feeds, can solve the problems of restricting the comprehensive utilization of flaxseed meal, reducing the nutritional value of protein, etc. The effect of the body's immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

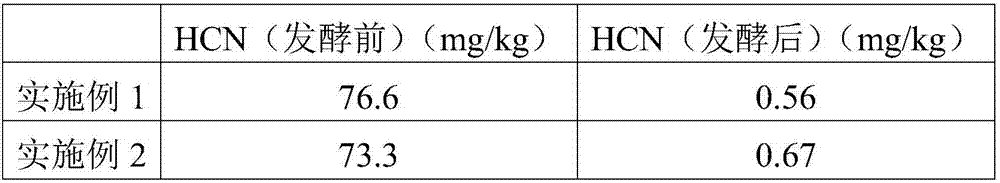

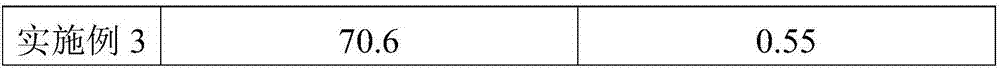

Embodiment 1

[0031] A preparation method of compound plant protein fertilizer, the concrete steps are as follows:

[0032] (1) Preparation of solid-state fermentation medium: after mixing sunflower seed meal, linseed meal and bran at a mass ratio of 3:5:2, add water to obtain a solid-state fermentation medium with a water content of 40%; the sunflower seeds Meal and linseed meal are dehulled sunflower meal and linseed meal;

[0033] (2) Preparation of strain seed solution:

[0034] A. Preparation of Lactobacillus plantarum seed solution: activate the thallus in the bacterial preservation tube for 3 generations, then inoculate it into MRS medium, culture at 37°C for 18 hours, and let it stand for cultivation to obtain the bacterial seed solution;

[0035] B. Preparation of Lactobacillus licheniformis seed liquid: activate the thalline in the bacteria preservation tube for 3 generations, then inoculate it into a nutrient agar medium, cultivate it at 26°C for 24 hours, and cultivate it stati...

Embodiment 2

[0045] A preparation method of compound plant protein fertilizer, the concrete steps are as follows:

[0046] (1) Preparation of solid-state fermentation medium: after mixing sunflower seed meal, linseed meal and bran at a mass ratio of 2:2:1, add water to obtain a solid-state fermentation medium with a water content of 50%; the sunflower seeds Meal and linseed meal are dehulled sunflower meal and linseed meal;

[0047] (2) Preparation of strain seed solution:

[0048]A. Preparation of Lactobacillus plantarum seed liquid: activate the thallus in the bacteria preservation tube for 3 generations, then inoculate it into MRS medium, cultivate it at 35°C for 24 hours, and cultivate it statically to obtain the bacterial seed liquid;

[0049] B. Preparation of Lactobacillus licheniformis seed liquid: activate the thalline in the bacteria preservation tube for 3 generations, then inoculate it into a nutrient agar medium, cultivate it at 30° C. for 18 hours, and cultivate it staticall...

Embodiment 3

[0059] A preparation method of compound plant protein fertilizer, the concrete steps are as follows:

[0060] (1) Preparation of solid-state fermentation medium: after mixing sunflower seed meal, linseed meal and bran at a mass ratio of 5:3:2, add water to obtain a solid-state fermentation medium with a water content of 60%; the sunflower seeds Meal and linseed meal are dehulled sunflower meal and linseed meal;

[0061] (2) Preparation of strain seed solution:

[0062] A. Preparation of Lactobacillus plantarum seed solution: activate the thallus in the bacteria preservation tube for 3 generations, then inoculate it into MRS medium, cultivate it at 36°C for 20 hours, and cultivate it statically to obtain the bacterial seed solution;

[0063] B. Preparation of Lactobacillus licheniformis seed liquid: activate the thalline in the bacteria preservation tube for 3 generations, then inoculate it into a nutrient agar medium, cultivate it at 28°C for 20 hours, and cultivate it static...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com