Application of pH-sensitive coaxial polylactate caprolactone PLCL/gelatin double drug-loaded fiber scaffold

A polylactide caprolactone and gelatin dual-loading technology, which is applied in medical science, prosthesis and other directions, can solve problems such as the inability to meet experimental needs, and achieve the effects of strong mechanical properties, simple experimental principle, and good biocompatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042](1) Weigh 0.452g of gelatin and dissolve it in 3mL of hexafluoroisopropanol (HFIP).

[0043] (2) Prepare sodium bicarbonate as a saturated solution, measure 0.217mL sodium bicarbonate saturated solution, add it to the above solution, then add 0.0453g ciprofloxacin, stir with a magnetic stirrer for 27h, until the solute is completely dissolved in the solvent , to obtain shell gelatin spinning solution;

[0044] (3) Weigh 0.154g PLCL (PCL:PLLA=1:1) and dissolve it in 3mL hexafluoroisopropanol (HFIP), then add 0.0752g DOX, stir with a magnetic stirrer for 28h, until the solute is completely dissolved in the solvent, Obtain the core layer PLCL spinning solution;

[0045] (4) Extract the above spinning solution with a 5mL syringe, fix it on the coaxial electrospinning device, adjust the spinning parameters for electrospinning, the ejection flow rate is 0.7mL / h for the shell layer, 0.4mL / h for the core layer, and the static voltage 17kV, the receiving distance is 28cm, the r...

Embodiment 2

[0050] (1) Weigh 0.450g of gelatin and dissolve it in 3mL of hexafluoroisopropanol (HFIP);

[0051] (2) Prepare sodium bicarbonate as a saturated solution, measure 0.219mL sodium bicarbonate saturated solution, add to the above solution, and stir with a magnetic stirrer for 27h until the solute is completely dissolved in the solvent to obtain pure gelatin spinning solution;

[0052] (3) Use a 5mL syringe to extract the above spinning solution, adjust the spinning parameters for electrospinning, the spray flow rate is 0.8mL / h, the static voltage is 15kV, the receiving distance is 25cm, the ambient temperature is 25°C, and the humidity is 30°C. -40%, the spinning time is 5h.

[0053] (5) According to the above steps, the obtained pure gelatin fiber scaffold was dried in a vacuum oven for 24 hours. Put the dried fiber into 25% glutaraldehyde steam, cross-link for 8 hours, put it in a ventilated place to make the glutaraldehyde volatilize completely.

[0054] (6) Cut the fiber t...

Embodiment 3

[0056] (1) Weigh 0.156g PLCL (PCL:PLLA=1:1) and dissolve it in 3mL of hexafluoroisopropanol (HFIP), and stir with a magnetic stirrer for 26h until the solute is completely dissolved in the solvent to obtain PLCL spinning solution.

[0057] (4) Extract the above-mentioned spinning solution with a 5mL syringe, fix it on the electrospinning device, adjust the spinning parameters for electrospinning, the spray flow rate is 0.4mL / h, the static voltage is 17kV, the receiving distance is 27cm, and the ambient temperature The temperature is 25°C, the humidity is 30-40%, and the spinning time is 6h.

[0058] (5) According to the above steps, the obtained polycaprolactone (PLCL) fiber support was placed in a vacuum drying oven for 24 hours, and the dried fiber support was placed in 25% glutaraldehyde vapor, cross-linked for 9 hours, and ventilated. to completely evaporate the glutaraldehyde.

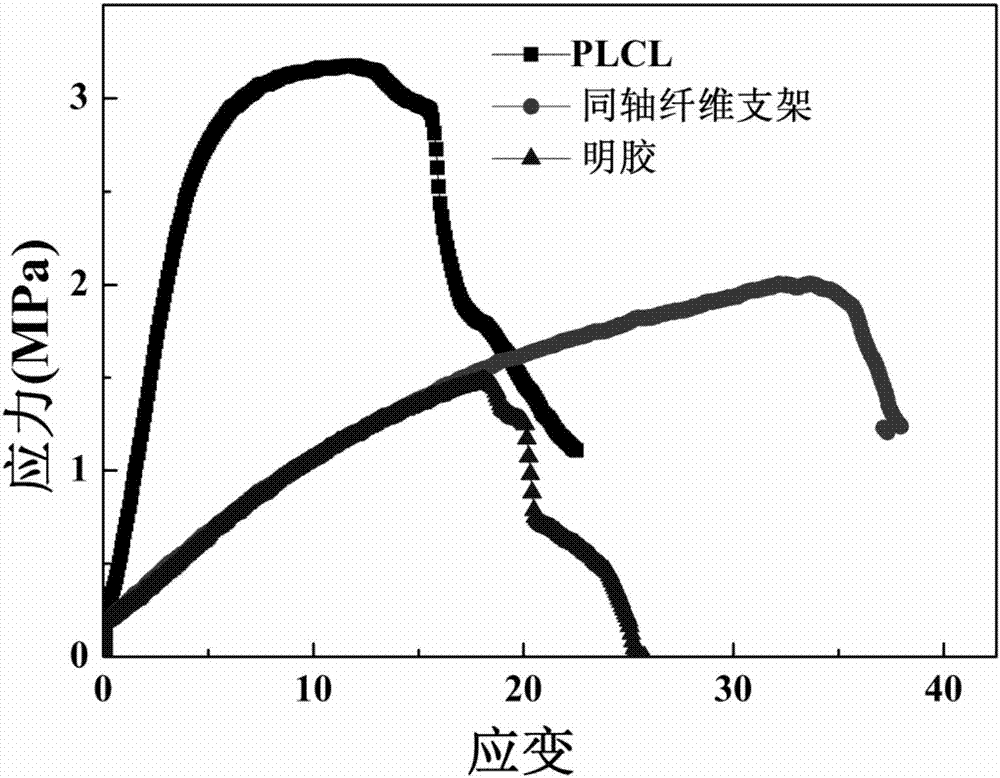

[0059] (6) Cut the fiber to a size of 1*5cm, fix it on a mechanical tester (HY-9940FS, China)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com