nico2s4 nanometer material and preparation method thereof

A nanomaterial and nanosheet technology, applied in the field of nanomaterials, can solve the problems of high cost, high energy consumption, complicated process, etc., and achieve the effects of being conducive to industrialized production, large specific surface area, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The invention provides a NiCo 2 S 4 The preparation method of nanometer material is characterized in that, comprises the following steps:

[0056] A) After mixing the soluble cobalt source, the soluble nickel source, urea and the solvent, a reaction precursor solution is obtained;

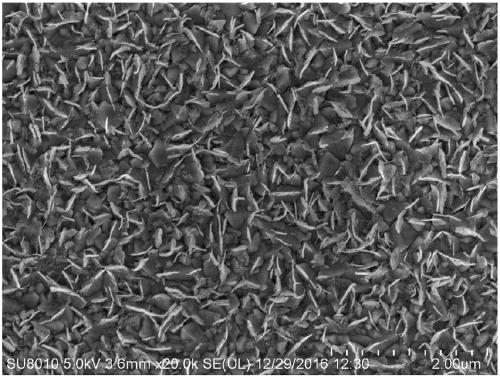

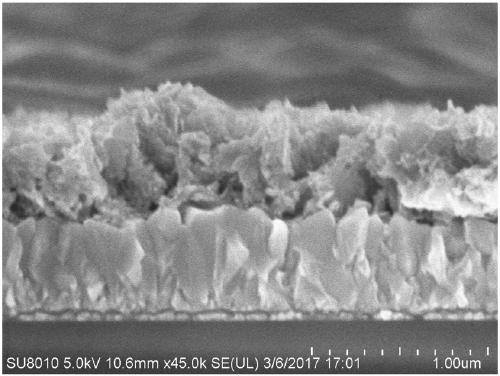

[0057] B) Place the conductive substrate in the reaction precursor solution obtained in the above steps, react under the action of microwaves, and then undergo heat treatment to obtain NiCo 2 o 4 Nanosheets;

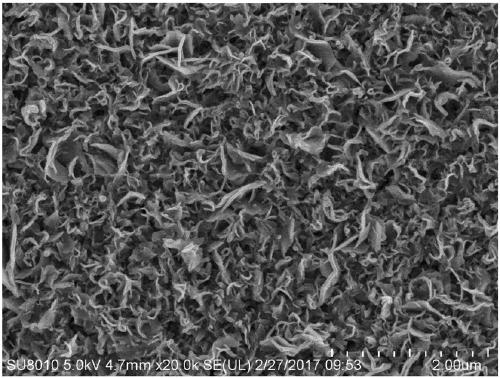

[0058] C) the NiCo obtained by the above steps 2 o 4 After the nanosheets react with sulfide again, NiCo 2 S 4 nanomaterials.

[0059] The invention firstly mixes soluble cobalt source, soluble nickel source, urea and solvent to obtain reaction precursor liquid.

[0060] The present invention has no special restrictions on the soluble cobalt source, and the soluble cobalt source well known to those skilled in the art can be used. Those skilled in the art can select and adjust ...

Embodiment 1

[0107] FTO conductive glass cleaning steps: Put the FTO conductive glass and the three-neck flask into acetone, absolute ethanol and deionized water respectively for ultrasonic cleaning for 15 minutes, and then dry them.

[0108] Weigh cobalt nitrate hydrate (Co(NO 3 ) 2 ·6H 2 O)0.88g, nickel nitrate hydrate (Ni(NO 3 ) 2 ·6H 2 O) 0.44g, the mass ratio of the two remains 2:1, urea (H 2 NCONH 2 ) 0.90g, dissolved in 100ml deionized water, stirred by magnetic force for 30 minutes until fully dissolved, then first put the FTO conductive glass conductive side down into the three-necked flask, then slowly pour the above reaction precursor into the three-necked flask, and put The three-necked flask was placed in a microwave oven for constant temperature reaction at constant power. The reaction power was 700W, the reaction temperature was 90°C, and the reaction time was 30 minutes. After the constant temperature reaction was completed, the FTO conductive glass with the product d...

Embodiment 2

[0123] FTO conductive glass cleaning steps: Put the FTO conductive glass and the three-neck flask into acetone, absolute ethanol and deionized water respectively for ultrasonic cleaning for 15 minutes, and then dry them.

[0124] Weigh cobalt nitrate hydrate (Co(NO 3 ) 2 ·6H 2 O)0.88g, nickel nitrate hydrate (Ni(NO 3 ) 2 ·6H 2 O) 0.44g, the mass ratio of the two remains 2:1, urea (H 2 NCONH 2 ) 0.90g, dissolved in 100ml deionized water, stirred by magnetic force for 30 minutes until fully dissolved, then first put the FTO conductive glass conductive side down into the three-necked flask, then slowly pour the above reaction precursor into the three-necked flask, and put The three-necked flask was placed in a microwave oven for a constant temperature reaction at a constant power. The reaction power was 800W, the reaction temperature was 100°C, and the reaction time was 2 hours. After the constant temperature reaction was completed, the FTO conductive glass with the product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com