Bifunctional alkenyl phenoxy compound as well as preparation method thereof and modified soluble bismaleimide resin thereby

A technology of bismaleimide resin and bismaleimide, which is applied in the preparation of carbon-based compounds, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of low bonding strength and poor dielectric properties problems, to achieve the effect of increasing charge transfer complexation, excellent thermal stability, and highlighting dilution heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

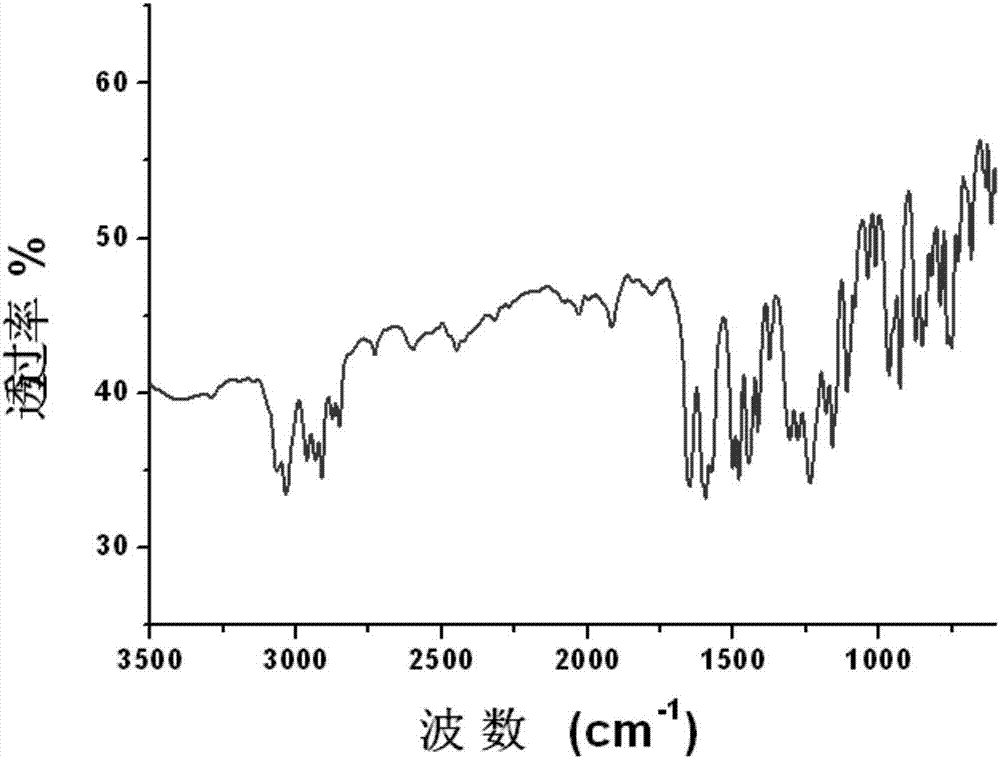

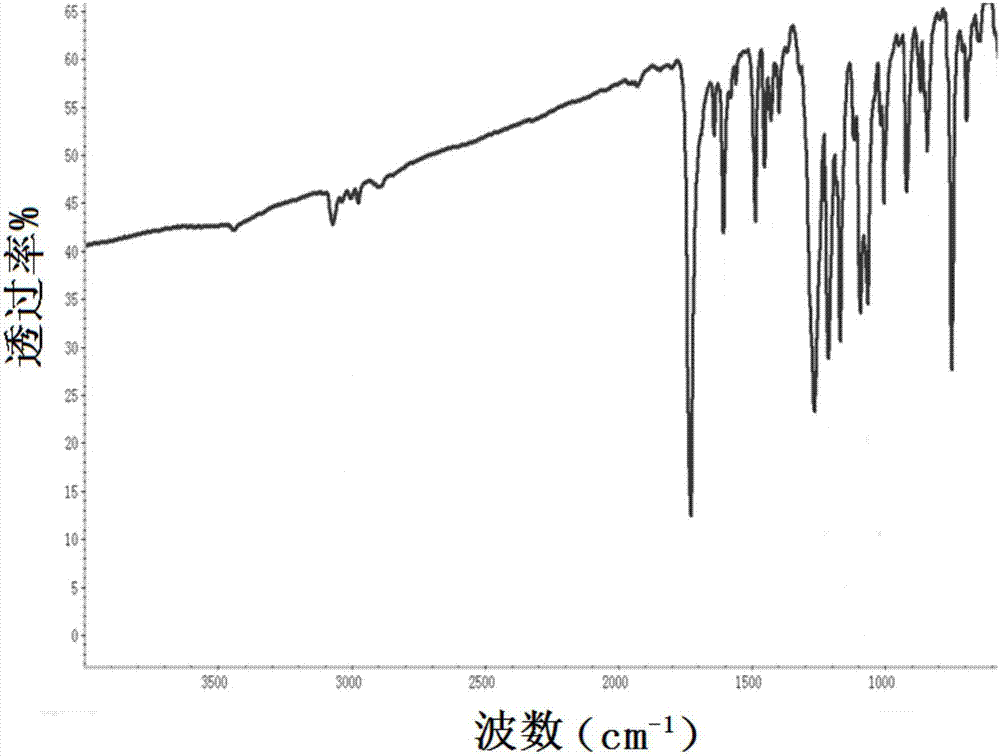

Image

Examples

specific Embodiment approach 1

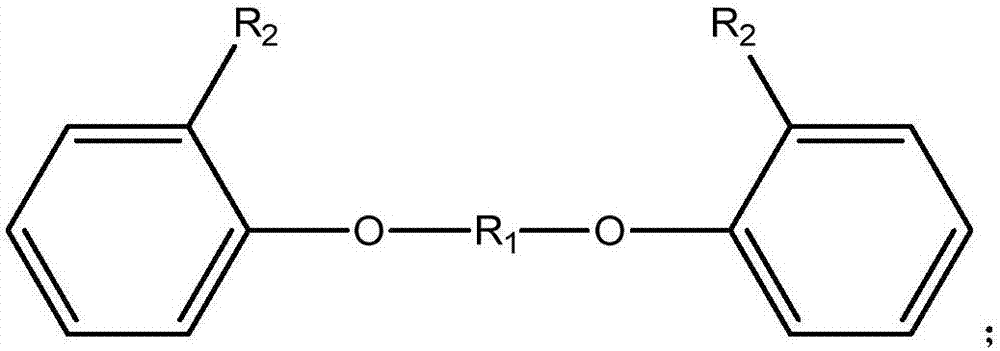

[0029] Specific embodiment 1: The general structural formula of a difunctional alkenylphenoxy compound in this embodiment is:

[0030]

[0031] The R 1 for

[0032] The R 2for -CH=CH-CH 3 or -CH 2 -CH=CH 2 .

[0033] The beneficial effect of this embodiment is: a difunctional alkenylphenoxy compound prepared in this embodiment. First, the polymerization of diallyl bisphenol A and bis-hormone will first undergo ENE addition and "Diels–Alder" reaction. Due to the presence of weak links with poor heat resistance in the structure of diallyl bisphenol A, such as -C(CH 3 ) 2 -, the lower thermal decomposition temperature and glass transition temperature have seriously affected the high-temperature use effect of Shuangma. After the alkenyl phenoxy compound is polymerized with double horses, the molecular chain has a high degree of phenylation and high structural symmetry, and the ether bond (-O-), carbonyl (C=O), fluorine side group in the molecular structure , The i...

specific Embodiment approach 2

[0037] Specific embodiment two: the preparation method of a kind of difunctional alkenyl phenoxy compound described in this embodiment is carried out according to the following steps:

[0038] Mix p-phenylene fluoride and 2-alkenylphenol to obtain a mixture, then add the mixture and catalyst to the solvent and stir for 10h to 20h to obtain a reaction system, raise the temperature of the reaction system to 60°C to 80°C, and Under the condition of ℃~80℃, react for 1h~5h, then raise the temperature of the reaction system to 110℃~170℃, and under the condition of 110℃~170℃, react for 2h~6h, after the reaction, cool down to room temperature, To obtain a crude product, filter the crude product with a 200-800-mesh drying screen, add ethanol to the filtrate for 3h-5h, filter the precipitated solution to obtain a precipitate, and then wash the precipitate with methanol for 3 to 5 hours times, and finally dry to obtain the difunctional alkenyl phenoxy compound;

[0039] The molar ratio ...

specific Embodiment approach 3

[0040] Specific embodiment three: the difference between this embodiment and specific embodiment two is: the described p-phenylene difluoride is

[0041] Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com