A kind of crown ether immobilized glass fiber material and preparation method thereof

A glass fiber and crown ether technology is applied in the field of crown ether immobilized glass fiber material and its preparation. Simple and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

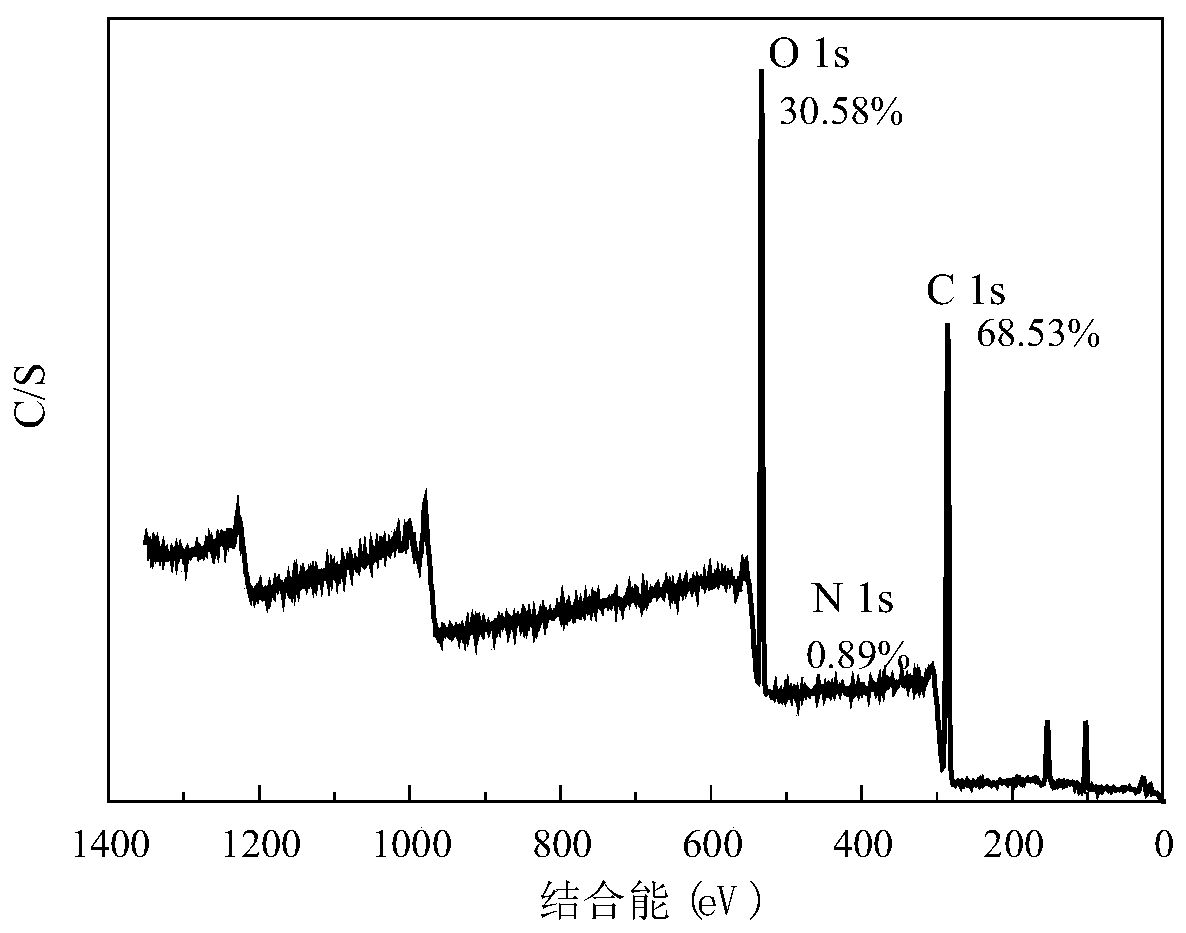

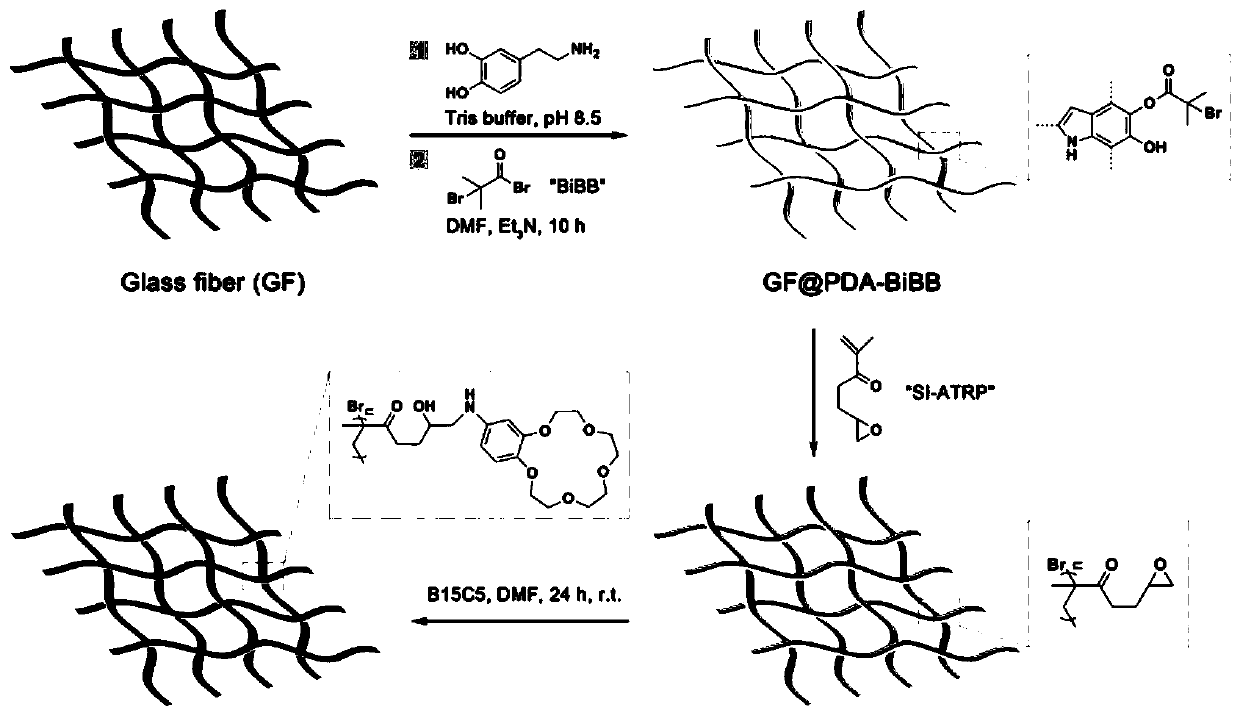

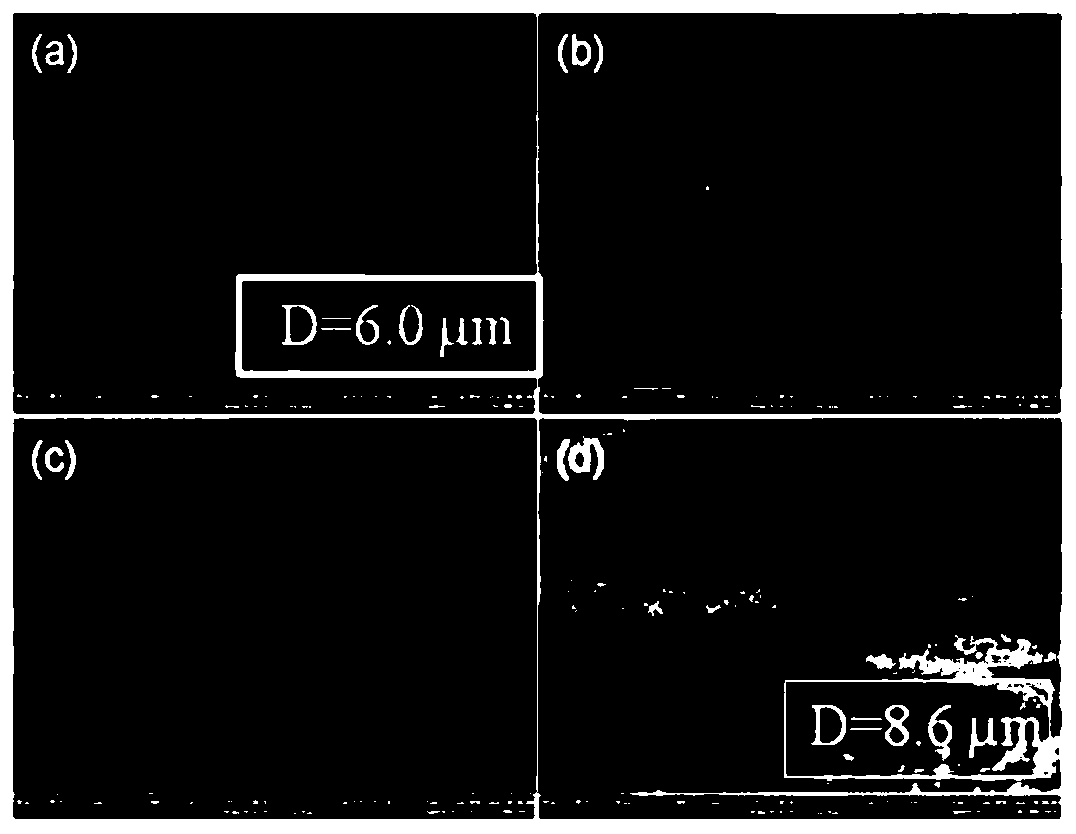

Embodiment 1

[0031] Cut 2×4cm 2 Add the original glass fiber mat to the Tris salt solution of 2g / L dopamine, shake at constant temperature for 24h, wash and dry repeatedly with deionized water and ethanol; put the above glass fiber mat material in 60mL DMF, add 1.5mL triethyl ether Add 1.5mL of 2-bromoisobutyryl bromide under the protection of inert gas, react at room temperature for 12h, wash and dry repeatedly with DMF and ethanol; put the above glass fiber mat material in 3.0mL of anisole, add 3.0mL of methyl Glycidyl acrylate, 33.0 μL ethyl 2-bromoisobutyrate and 740 μL azobisisobutyronitrile in DMF (concentration 1.0 mg / L), under the protection of an inert gas atmosphere, add 1.0 mL copper bromide and tris DMF solution of (2-dipicolylmethyl)amine (concentrations of the two are 1.0 and 3.0mg / L respectively), 60 ℃ oil bath for 24h, THF, DMF and ethanol repeatedly washed and dried; the above-mentioned glass fiber mat material was placed in 4-Aminobenzo15-crown-5 in DMF solution (concent...

Embodiment 2

[0038] Cut 2×4cm 2 Add the original glass fiber mat to the Tris salt solution of 2g / L dopamine, shake at constant temperature for 24h, wash and dry repeatedly with deionized water and ethanol; put the above glass fiber mat material in 60mL DMF, add 1.5mL triethyl ether Add 1.5mL of 2-bromoisobutyryl bromide under the protection of inert gas, react at room temperature for 12h, wash and dry repeatedly with DMF and ethanol; put the above glass fiber mat material in 3.0mL of anisole, add 3.0mL of methyl Glycidyl acrylate, 33.0 μL ethyl 2-bromoisobutyrate and 1.0 mL ascorbic acid in DMF (concentration 3.97 mg / L), under the protection of an inert gas atmosphere, add 1.0 mL copper bromide and pentamethyldiethylene The DMF solution of triamine (both concentrations are 1.0 and 2.3mg / L respectively), 60 ℃ oil bath 24h, THF, DMF and ethanol wash repeatedly and dry; Crown-5 in DMF solution (concentration: 25g / L), reflux reaction at 70°C for 6h, repeated washing with DMF and ethanol, and ...

Embodiment 3

[0040] Cut 2×4cm 2 Add the original glass fiber mat to the Tris salt solution of 2g / L dopamine, shake at constant temperature for 24h, wash and dry repeatedly with deionized water and ethanol; put the above glass fiber mat material in 60mL DMF, add 1.5mL triethyl ether Add 1.5mL of 2-bromoisobutyryl bromide under the protection of inert gas, react at room temperature for 12h, wash and dry repeatedly with DMF and ethanol; put the above glass fiber mat material in 3.0mL of anisole, add 3.0mL of methyl Glycidyl acrylate, 33.0 μL ethyl 2-bromoisobutyrate and 740 μL azobisisobutyronitrile in DMF (concentration 1.0 mg / L), under the protection of an inert gas atmosphere, add 1.0 mL copper bromide and tris DMF solution of (2-dipicolylmethyl)amine (concentrations of the two are 1.0 and 3.0mg / L respectively), 60 ℃ oil bath for 24h, THF, DMF and ethanol repeatedly washed and dried; the above-mentioned glass fiber mat material was placed in 4-Aminobenzo-18-crown-6 in DMF solution (concen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com