Modified diatomite thermal insulation mortar and preparation method thereof

A technology of thermal insulation mortar and diatomite, which is applied in the field of thermal insulation mortar, can solve the problems affecting the safety and functionality of buildings, low mechanical strength of thermal insulation mortar, and high dry density of products, so as to improve thermal insulation and sound insulation, improve safety and Durability and the effect of a wide range of raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

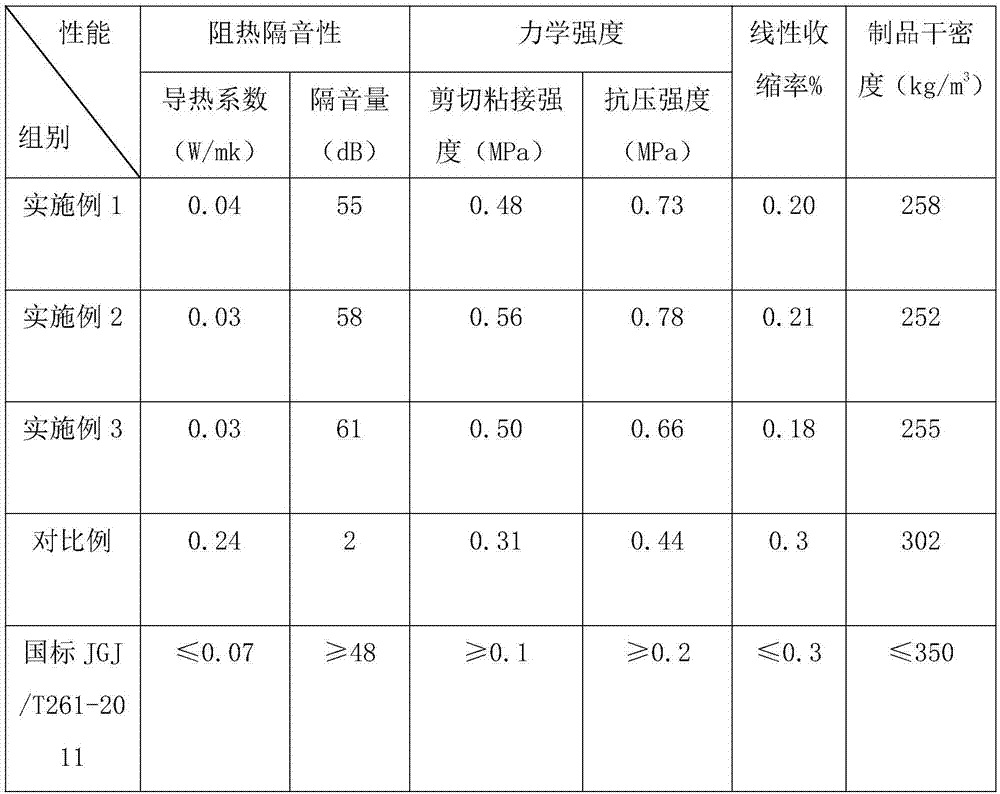

Examples

Embodiment 1

[0025] A modified diatomite insulation mortar, prepare the following raw materials: cement 80kg, modified diatomite 30kg, quartz sand 15kg, lime paste 10kg, alumina fiber 10kg, aerated aluminum powder 8kg, floating beads 5kg, phillipsite 10kg, 6kg of mullite, 6kg of iron oxide powder, 4kg of styrene-acrylic emulsion and 1kg of additives;

[0026] The modified diatomite is made from the following raw materials: 30kg of diatomite, 8kg of titanium dioxide, 4kg of lithopone, 3kg of lignin, 10kg of expanded perlite, 6kg of ferric chloride, 3kg of n-butyraldehyde-aniline condensate , praseodymium oxide 3kg, beeswax 6kg, 10,10'-oxobisphenoxarsenic 3kg, 2,2'-thiobis(4-tert-octylphenoxy)nickel 3kg; its preparation method is diatom The soil is soaked in 8% hydrochloric acid solution for 40 minutes, and the obtained material is dried after suction filtration, and then mixed with expanded perlite, and calcined at 680°C for 1 hour, taken out and cooled to room temperature, mixed with beesw...

Embodiment 2

[0035] A modified diatomite insulation mortar, prepare the following raw materials: cement 90kg, modified diatomite 40kg, quartz sand 20kg, lime paste 15kg, alumina fiber 12kg, aerated aluminum powder 10kg, floating beads 10kg, phillipsite 15kg, 9kg of mullite, 8kg of iron oxide powder, 6kg of styrene-acrylic emulsion and 3kg of additives;

[0036] The modified diatomite is made from the following raw materials: 30kg of diatomite, 8kg of titanium dioxide, 4kg of lithopone, 3kg of lignin, 10kg of expanded perlite, 6kg of ferric chloride, 3kg of n-butyraldehyde-aniline condensate , praseodymium oxide 3kg, beeswax 6kg, 10,10'-oxobisphenoxarsenic 3kg, 2,2'-thiobis(4-tert-octylphenoxy)nickel 3kg; its preparation method is diatom The soil is soaked in 10% hydrochloric acid solution for 40 minutes, and after suction filtration, the obtained material is dried, mixed with expanded perlite, calcined at 700°C for 1.5 hours, taken out and cooled to room temperature, mixed with beeswax, pa...

Embodiment 3

[0045] A modified diatomite insulation mortar, prepare the following raw materials: cement 100kg, modified diatomite 50kg, quartz sand 25kg, lime paste 20kg, alumina fiber 20kg, aerated aluminum powder 12kg, floating beads 15kg, phillipsite 20kg, 12kg of mullite, 10kg of iron oxide powder, 8kg of styrene-acrylic emulsion and 5kg of additives;

[0046] The modified diatomite is made from the following raw materials: 30kg of diatomite, 8kg of titanium dioxide, 4kg of lithopone, 3kg of lignin, 10kg of expanded perlite, 6kg of ferric chloride, 3kg of n-butyraldehyde-aniline condensate , praseodymium oxide 3kg, beeswax 6kg, 10,10'-oxobisphenoxarsenic 3kg, 2,2'-thiobis(4-tert-octylphenoxy)nickel 3kg; its preparation method is diatom The soil is soaked in 12% hydrochloric acid solution for 60 minutes, and after suction filtration, the obtained material is dried, mixed with expanded perlite, calcined at 720°C for 2 hours, taken out and cooled to room temperature, mixed with beeswax, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com