Ordered Pt-TiO2/InP nanowire array electrode material applied to hydrogen production through water decomposition and preparation method of material

A nanowire array, photo-splitting water hydrogen production technology, applied in electrodes, metal material coating process, electrolysis process, etc., can solve the problems of poor photochemical stability, narrow band gap, high carrier mobility, and save energy. Material, good photochemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

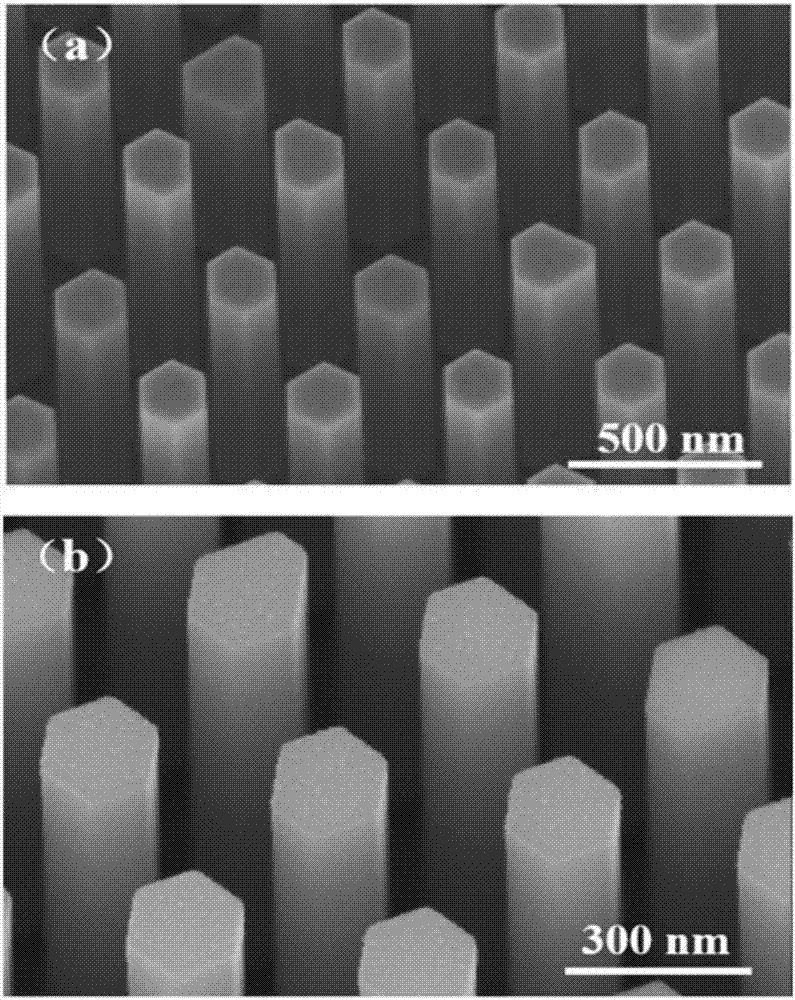

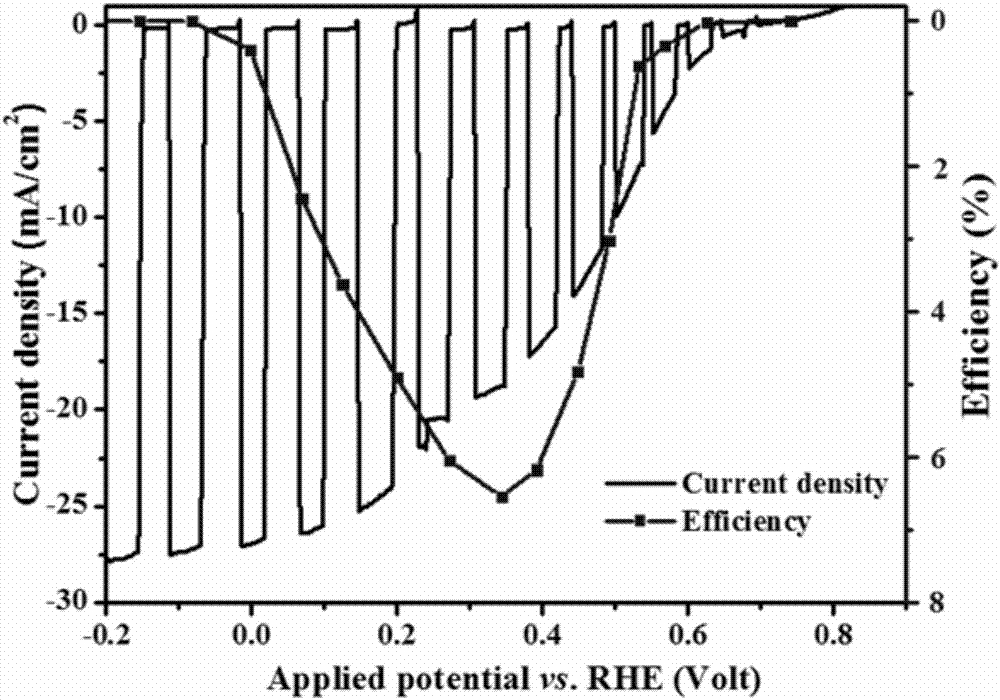

[0033] Using nanoimprinting and MOCVD technology to realize the controlled growth of large-area periodic and ordered InP nanowire arrays, further using ALD and electron beam evaporation technology to successively deposit nano-TiO on the surface of InP nanowires 2 Protective layer and Pt co-catalyst layer, a new type of high-performance ordered Pt-TiO applied to photolysis of water for hydrogen production 2 / InP nanowire array electrode material, the specific preparation steps are as follows:

[0034] 1. Select the InP(111)A substrate as the substrate, and use the plasma enhanced chemical vapor deposition method to deposit a layer of SiO with a thickness of 30nm on the surface of the InP(111)A substrate. 2 .

[0035] 2. Using nanoimprint technology to obtain a large-area periodic and ordered hole structure on the surface of the InP substrate, the specific preparation process steps are as follows:

[0036] SiO on the substrate surface by spin-coating 2 Coat PMMA (polymethyl m...

Embodiment 2

[0045] The preparation method of this embodiment is the same as that of Example 1, except that the SiO deposited by PECVD is used in step 1. 2 The thickness is 40nm, and the 1% HF etching time in step 2 is 80s, that is, the SiO on the surface of the InP(111)A substrate 2 After increasing the layer thickness, for SiO on InP substrate 2 layer to obtain the pore structure characteristics required for epitaxial growth, the HF etching time also needs to be extended accordingly. Ordered Pt-TiO obtained by this preparation method 2 The performance, efficiency and photochemical stability of the / InP nanowire array electrode material are basically consistent with the results of Example 1.

Embodiment 3

[0047] The preparation method of this example is the same as that of Example 1, except that the template parameters used in the nanoimprinting technology in Step 2 are adjusted to 100 nm in pore size, the same pore depth, and 400 nm in distance between holes. This fabrication method adjusts the microstructural parameters (including diameter, spacing, length, etc.) 2 / InP nanowire array electrode material's specific surface area size, light absorption performance, photo-splitting water hydrogen production performance and efficiency. The Pt-TiO prepared in this example 2 The initial voltage of the photocurrent of the / InP nanowire array electrode material is basically unchanged, the performance and efficiency of hydrogen production by photolysis of water are reduced, and the saturated photocurrent density is 21.5mA / cm 2 , the energy conversion efficiency is 5.33%, and the photochemical stability is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com