Preparation method of carbon quantum dot-montmorillonite nanometer composite powder for latent fingerprint developing

A technology of carbon quantum dots and nano-composite, applied in chemical instruments and methods, applications, diagnostic records/measurements, etc., can solve problems such as poor application and low density of carbon quantum dots, and achieve low cost, clear display effect, and detailed features Easily distinguishable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

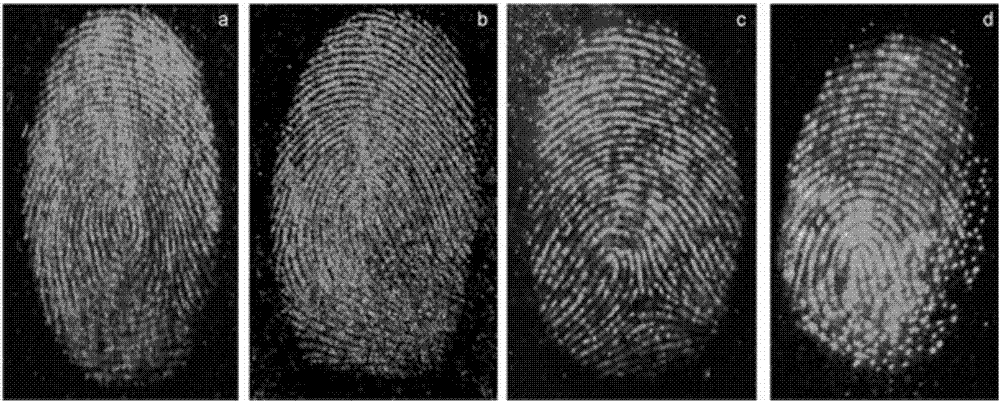

Image

Examples

Embodiment 1

[0025] Weigh 2.0g of citric acid and 0.2g of L-cysteine into a glass beaker, add 10mL of ultrapure water for ultrasonic dissolution, and heat in a microwave oven on high heat (power density >50W / L) for 5 minutes. Subsequently, the above product was dissolved in 5mL of ultrapure water to obtain a yellow transparent carbon quantum dot solution, which was set aside; another 0.25g of sodium montmorillonite was weighed into a 1.5mL centrifuge tube, and 1mL of the above carbon quantum dot solution was added, and mixed evenly Then let it stand at room temperature for 2 hours. The supernatant is removed by centrifugation, and the precipitate is dried to obtain a carbon quantum dot-montmorillonite nanocomposite with strong fluorescence, which is ground through a 600-mesh sieve to obtain a carbon quantum dot-montmorillonite nanocomposite powder.

[0026] Experiment one: the product that embodiment 1 is made carries out stability test:

[0027] The finished products were subjected to ...

Embodiment 2

[0042] Weigh 2.0g of citric acid and 0.1g of L-cysteine into a glass beaker, add 8mL of ultrapure water for ultrasonic dissolution, and heat in a microwave oven on high heat (power density>50W / L) for 3 minutes. Subsequently, the above product was dissolved in 5 mL of ultrapure water to obtain a yellow transparent carbon quantum dot solution, which was set aside; another 0.25 g of sodium montmorillonite was weighed in a 1.5 mL centrifuge tube, and 0.75 mL of the above carbon quantum dot solution was added, mixed After uniformity, it was left to stand at room temperature for 2 hours. The supernatant is removed by centrifugation, and the precipitate is dried to obtain a carbon quantum dot-montmorillonite nanocomposite with strong fluorescence, which is ground through a 600-mesh sieve to obtain a carbon quantum dot-montmorillonite nanocomposite powder.

[0043]The obtained product is carried out respectively by the experimental method of embodiment 1 in stability experiment, ani...

Embodiment 3

[0045] Weigh 2.0g of citric acid and 0.3g of L-cysteine into a glass beaker, add 16mL of ultrapure water for ultrasonic dissolution, and heat in a microwave oven on high heat (power density>50W / L) for 8 minutes. Subsequently, the above product was dissolved in 5 mL of ultrapure water to obtain a yellow transparent carbon quantum dot solution, which was set aside; another 0.25 g of sodium montmorillonite was weighed in a 1.5 mL centrifuge tube, and 1.25 mL of the above carbon quantum dot solution was added, mixed After uniformity, it was left to stand at room temperature for 5 hours. The supernatant is removed by centrifugation, and the precipitate is dried to obtain a carbon quantum dot-montmorillonite nanocomposite with strong fluorescence, which is ground through a 600-mesh sieve to obtain a carbon quantum dot-montmorillonite nanocomposite powder.

[0046] The obtained product is carried out respectively by the experimental method of embodiment 1 in stability experiment, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com