Method for concentrating and treating low-concentration waste gas containing volatile organic compounds

A technology of volatile organic compounds and treatment methods, applied in the direction of gaseous effluent wastewater treatment, gas treatment, chemical instruments and methods, etc., can solve the problems of limited application range, high cost of biological treatment, low B/C, etc., and achieve reduction Effect of investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

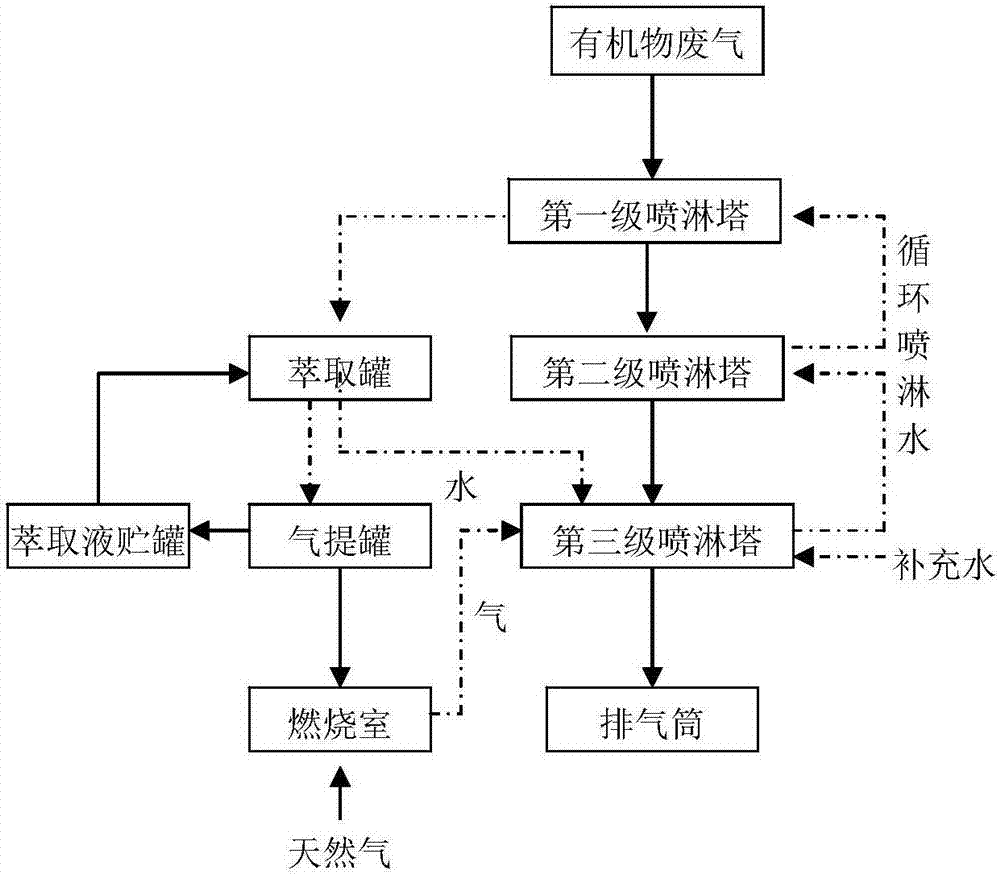

[0040] An organic waste gas is mainly xylene, containing some butanone and heavenly water (butyl acetate), and the air volume is 37500Nm 3 , the concentration of xylene in organic waste gas is 315mg / Nm 3 , non-methane total hydrocarbon concentration 528mg / Nm 3 .

[0041] The organic waste gas is discharged through the 25m exhaust pipe after the three-stage spray tower (Φ3500×4500).

[0042] Circulating water 50~150m 3 / h,

[0043] Exhaust stack organic waste gas outlet concentration xylene 25mg / Nm 3 , total non-methane hydrocarbons 38mg / Nm 3 .

[0044] The spray water is three-stage countercurrent, the COD of the first-stage wastewater is about 1200mg / L, pumped into the extraction tank with vegetable oil as the extraction agent, and the second-stage countercurrent extraction, the effluent COD<150mg / L, the extracted wastewater enters the third-stage spray In the circulating pool of the shower tower.

[0045] The extracted vegetable oil is heated by electric heating at 6...

Embodiment 2

[0048] The main component of an organic waste gas is heavenly water (butyl acetate), containing a small amount of xylene. Air volume 12000Nm 3 , the concentration of xylene in organic waste gas is 15mg / Nm 3 , non-methane total hydrocarbon concentration 248mg / Nm 3 .

[0049] The organic waste gas is discharged through the 15m exhaust pipe behind the secondary spray tower (Φ2500×3500).

[0050] Circulating water 15~50m 3 / h.

[0051] The concentration of xylene at the outlet of organic waste gas in the exhaust pipe is 5mg / Nm 3 , total non-methane hydrocarbons 28mg / Nm 3 .

[0052] The spray water is three-stage countercurrent, the COD of the first-stage wastewater is about 1200mg / L, pumped into the extraction tank with vegetable oil as the extraction agent, and the second-stage countercurrent extraction, the effluent COD<150mg / L, the extracted wastewater enters the third-stage spray In the circulating pool of the shower tower.

[0053] The extracted vegetable oil is heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com