Method for increasing biological gasification rate of oil reservoir residual oil and application of method

A technology for residual oil and oil reservoirs, applied in chemical instruments and methods, drilling compositions, earth-moving drilling, etc., which can solve the problem of slow hydrocarbon microbial degradation gas production rate, unsatisfactory gas production rate, reaction rate limitation, etc. problems, to achieve the effect of increasing the rate of biogasification, saving energy, and improving the reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

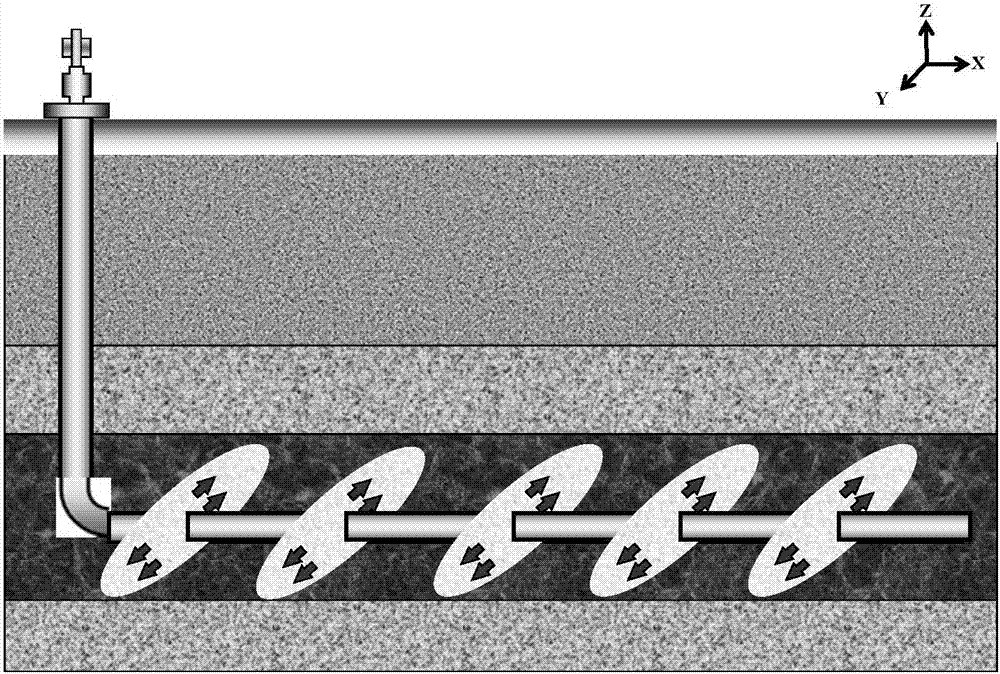

Embodiment 1

[0044] In a depleted oil reservoir in a certain block of Henan Oilfield, multi-stage fracturing of horizontal wells has been implemented. There are 8 fracturing stages, and each stage (half-fracture length 100 meters, fracture height 30 meters, fracture width 10 mm, porosity 50%) Inject about 50m 3 Activator, a total injection of activator 400m 3 , The activator composition is 0.5g / L urea, 0.25g / L dipotassium hydrogen phosphate, 0.05g / L magnesium sulfate and 0.01g / L yeast extract. Propants made of conductive materials are used for hydraulic fracturing, and then wires are connected to a DC power supply at the bottom of the well to construct electrodes. Set adjacent segments as anode and cathode respectively, set anode voltage to -0.20V vs. reference electrode voltage (NHE), cathode voltage to -0.35V vs. reference electrode voltage (NHE), and apply voltage for 90 days. After stop applying voltage, use 4000m 3 Water was used for displacement, and after 180 days of boredom, the...

Embodiment 2

[0046] In a depleted oil reservoir in a certain block of Jiangsu Oilfield, staged fracturing of a single well was implemented, with 2 fracturing stages. The target reservoir is relatively shallow and is a horizontal fracture. Inject about 30m into each section (half slit length 80m, slit height 40m, slit width 6mm, porosity 50%) 3 Activator, a total injection of activator 60m 3 , The activator composition is 0.8g / L ammonium chloride, 0.50g / L dipotassium hydrogen phosphate, 0.08g / L magnesium sulfate and 0.01g / L beef extract. Propants made of conductive materials are used for hydraulic fracturing, and then wires are connected to a DC power supply at the bottom of the well to construct electrodes. Set the adjacent segments as the anode and the cathode respectively, set the anode voltage to -0.15V vs. 3 Water was used for displacement. After 150 days of boredom, the initial production of natural gas after the well was opened was 16,000 cubic meters per day.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com