Construction method and application of carbon nanotube-fullerene complex-based non-enzymatic electrochemical sensor

A technology of fullerene complexes and carbon nanotubes, which is applied in the construction of non-enzyme electrochemical sensors, can solve the problems of difficult application of electrochemical sensors, poor electron transmission efficiency, and low detection sensitivity, so as to achieve the promotion of electron transmission rate, The effect of low detection limit and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

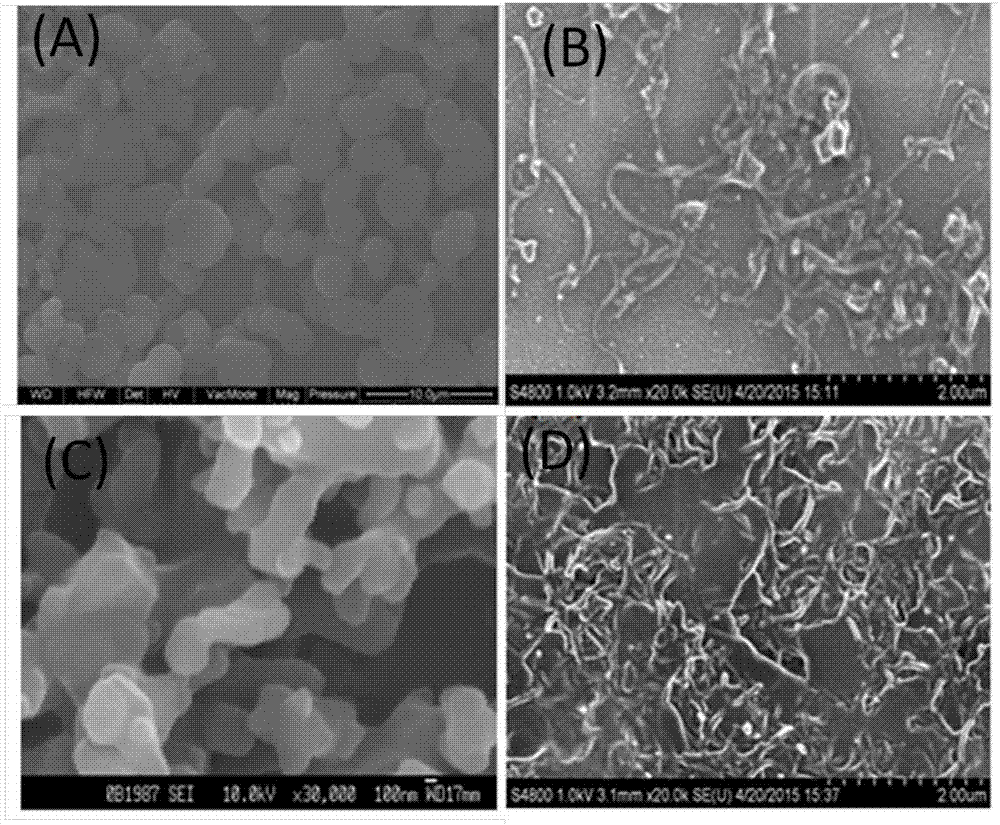

[0036] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred examples and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

[0037] 1.1 Instruments and reagents

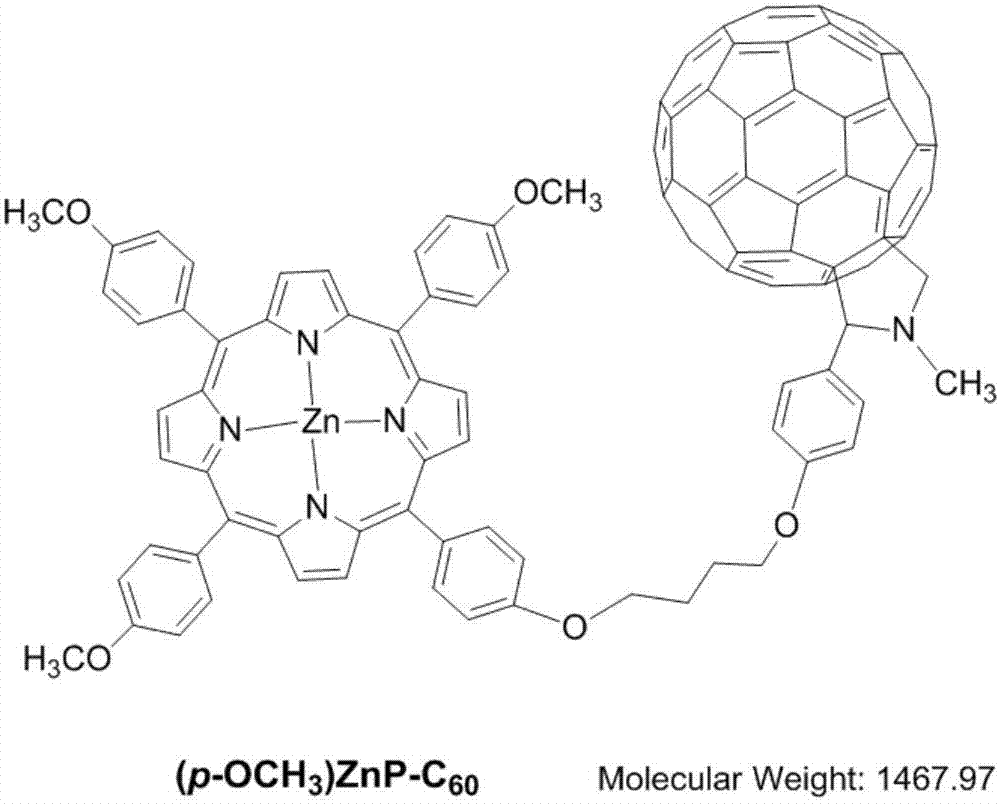

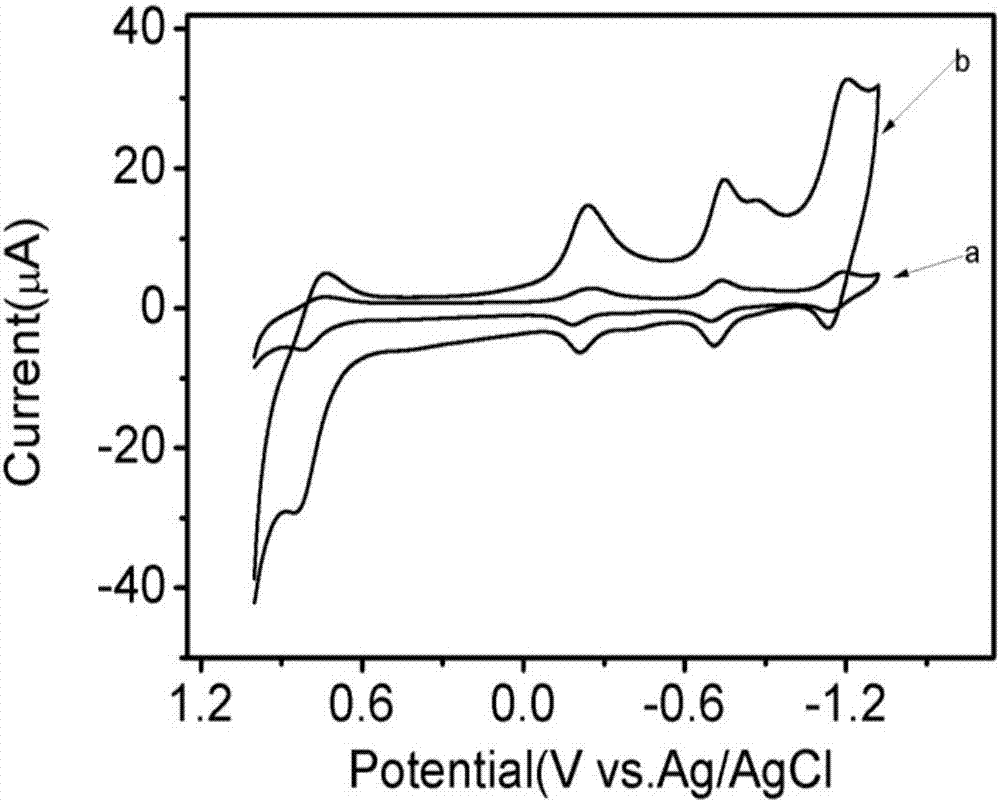

[0038] Electrochemical workstation (Shanghai Chenhua Company), three-electrode system: glassy carbon electrode (working electrode), platinum wire electrode (auxiliary electrode), Ag / AgCl electrode (reference electrode), SB1000 ultrasonic cleaning machine (Ningbo Xinzhi Company) , tetraoctyl ammonium bromide (TOAB, analytically pure), fullerene (C 60 , Shanghai Jingchun Reagent Co., Ltd.), toluene (analytical grade), nitrite, zinc porphyrin fullerene derivatives (p-OCH 3 )ZnP-C 60 (Abbr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com