Preparation method of mesoporous supported CuO-LaCoO3 catalyst

A supported catalyst, mesoporous technology, applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve the problems of limiting perovskite, complex composition, poor characteristics, etc. Good low-temperature catalytic activity and thermal stability, simple and easy-to-obtain raw materials, and low-cost preparation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Preparation of Mesoporous LaCoO with Large Specific Surface Area 3 Catalyst, it comprises the steps:

[0036] Preparation of template KIT-6: using P123 as template, n-butanol as silicon source, and tetraethyl silicate as silicon source, prepared by solvothermal method; the specific process is as follows: 6g of P123 and 6g of n-butanol were dissolved in 217g of deionized water and 11.4 In hydrochloric acid with a concentration of 37%, stir at 38°C for 1h until completely dissolved, then add 12.9g of tetraethyl silicate and continue to stir for 24h; transfer the resulting solution to a reaction kettle, and conduct a hydrothermal reaction at 100°C for 24h; cool the reaction kettle to room temperature , take out the lining, filter, wash, and dry to obtain a white powder; calcinate the obtained powder in a muffle furnace at 550°C for 5 hours to obtain the KIT-6 template. The TEM image of the prepared template KIT-6 is as follows Figure 4 It can be clearly seen from the fi...

Embodiment 2

[0044] Preparation of Mesoporous LaCoO with Large Specific Surface Area 3 Catalyst, it comprises the steps:

[0045] Weigh 8mmol of lanthanum nitrate and cobalt nitrate and dissolve them in 80ml of ethanol solution (the volume ratio of absolute ethanol to deionized water is 3:1), weigh 8mmol of citric acid monohydrate as a chelating agent and add it to the precursor, and stir overnight at room temperature ;

[0046] Slowly add 16mmol of the prepared template while stirring, heat and stir until viscous;

[0047] Transfer the wet gel to an oven to dry to obtain a dry gel, and bake it in an electric furnace for 2 hours to remove citric acid to obtain a black fluffy solid;

[0048] The black fluffy solid was calcined in a muffle furnace at a heating rate of 2 °C / min at 700 °C for 6 h to obtain template-containing LaCoO 3 black powder;

[0049] Use a sodium hydroxide solution with a concentration of 2mol / L, stir at 40°C for 12h to wash away SiO 2 , namely the mesoporous perovs...

Embodiment 3

[0052] Preparation of Mesoporous LaCoO with Large Specific Surface Area 3 Catalyst, it comprises the steps:

[0053] Weigh 8mmol of lanthanum nitrate and cobalt nitrate and dissolve them in 80ml of absolute ethanol, weigh 8mmol of citric acid monohydrate as a chelating agent and add them to the precursor, and stir overnight at room temperature;

[0054] Slowly add 16mmol of the prepared template while stirring, heat and stir until viscous;

[0055] Transfer the wet gel to an oven to dry to obtain a dry gel, and bake it in an electric furnace for 2 hours to remove citric acid to obtain a black fluffy solid;

[0056] The black fluffy solid was calcined in a muffle furnace at a heating rate of 2 °C / min at 700 °C for 6 h to obtain template-containing LaCoO 3 black powder;

[0057] Use a sodium hydroxide solution with a concentration of 2mol / L, stir at 40°C for 12h to wash away SiO 2 , namely the mesoporous perovskite LaCoO 3 , remember LaCoO 3 -C 1 h 0 .

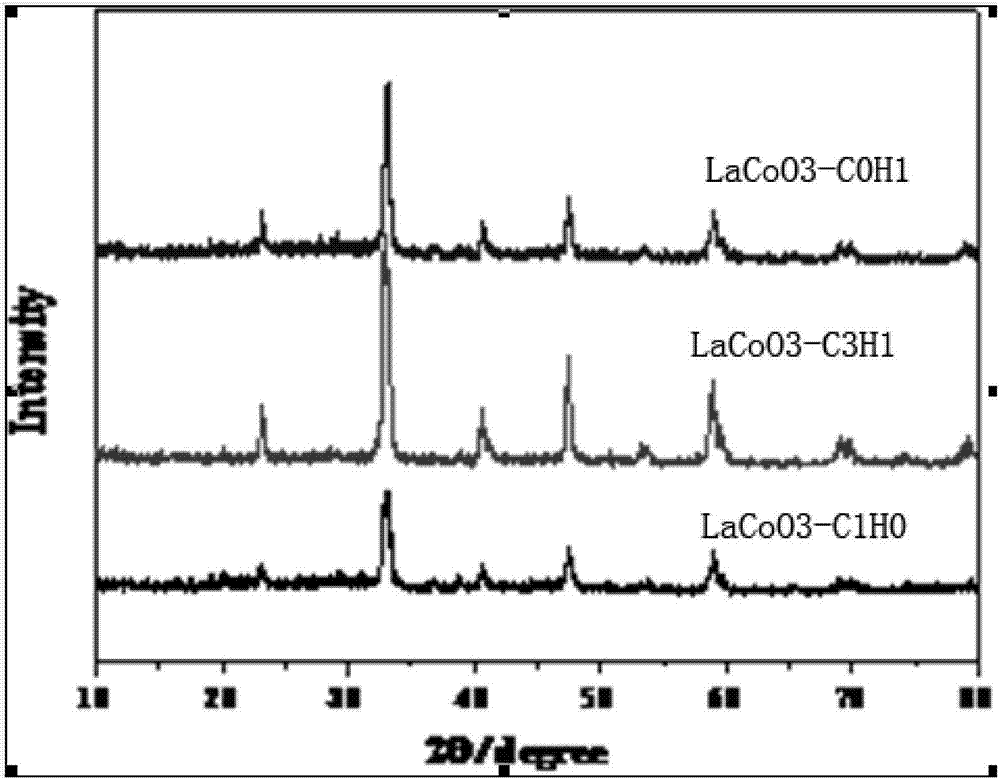

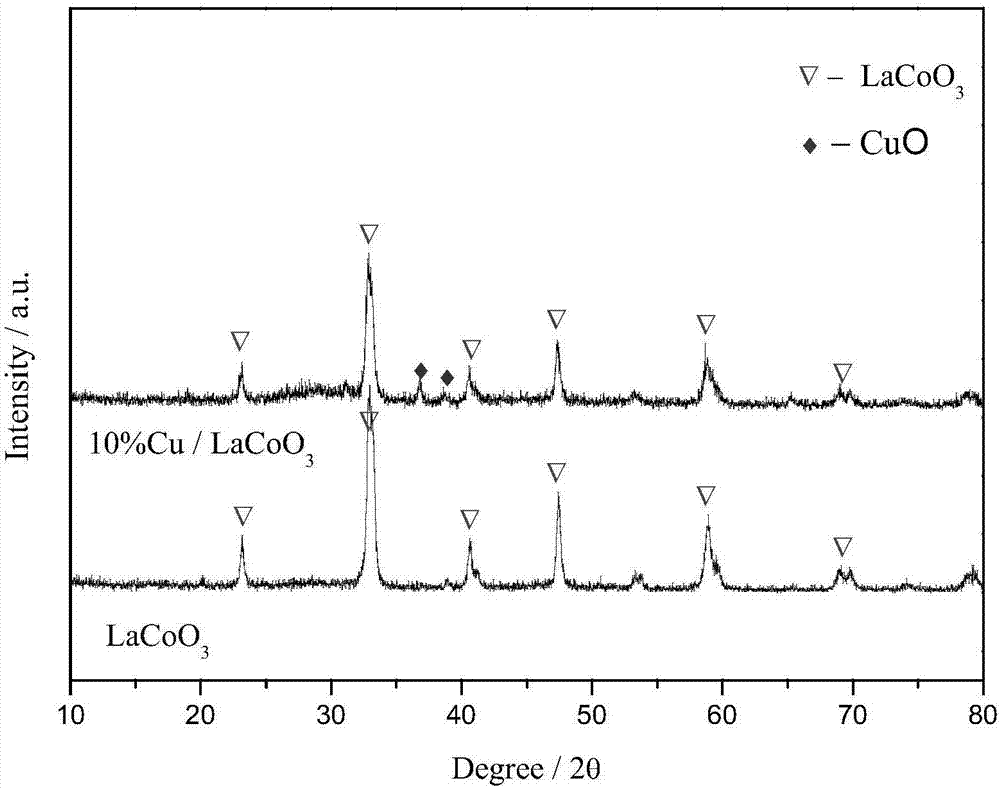

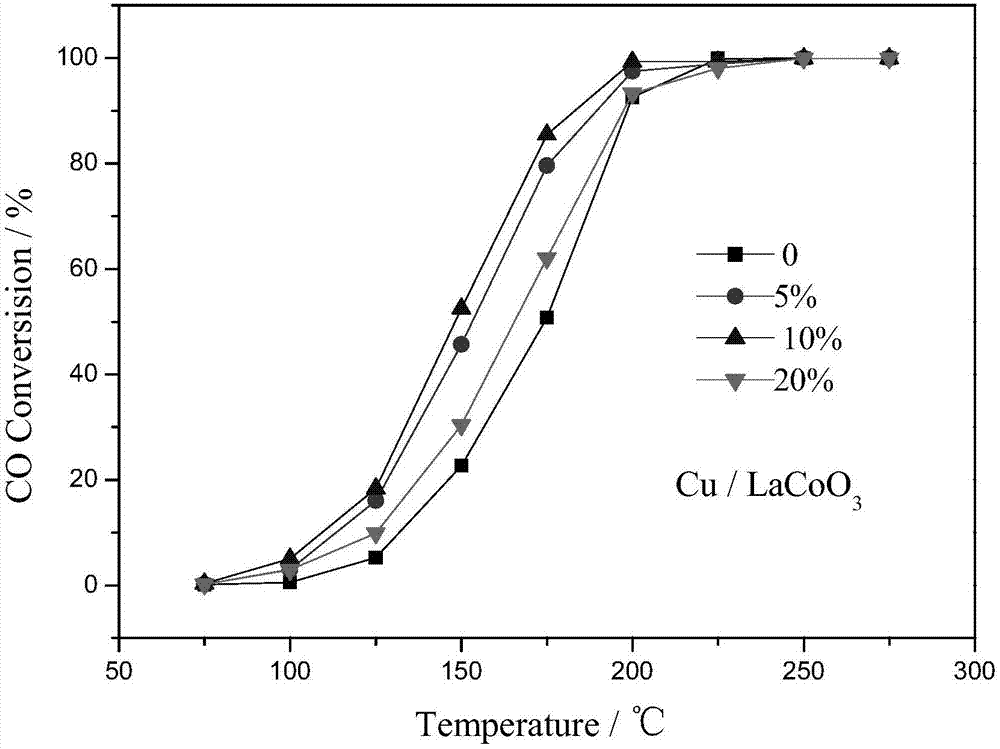

[0058] The resu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com