Method for extracting fucoxanthin from brown seaweeds

A fucoxanthin and brown algae technology, applied in the biological field, can solve the problems of low extraction efficiency, poor extraction effect, loss, etc., and achieve the effects of improving dissolution rate, saving time, and increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

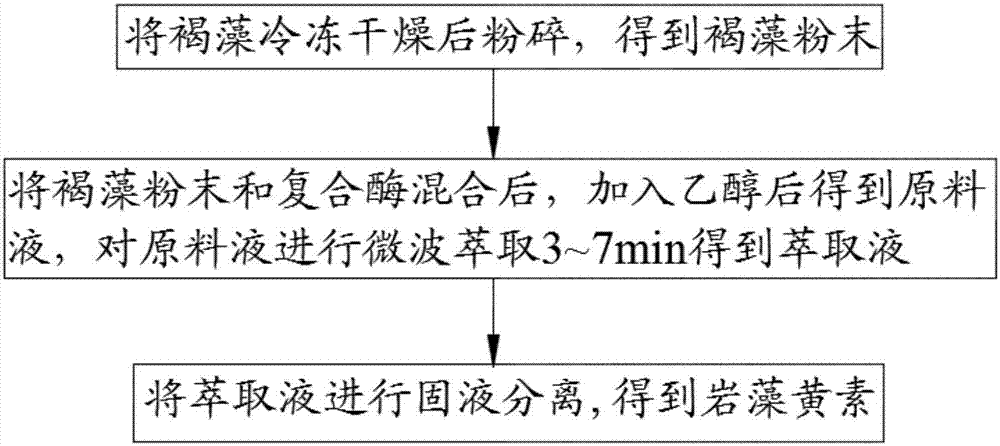

[0046] A method for extracting fucoxanthin from brown algae provided in this embodiment comprises:

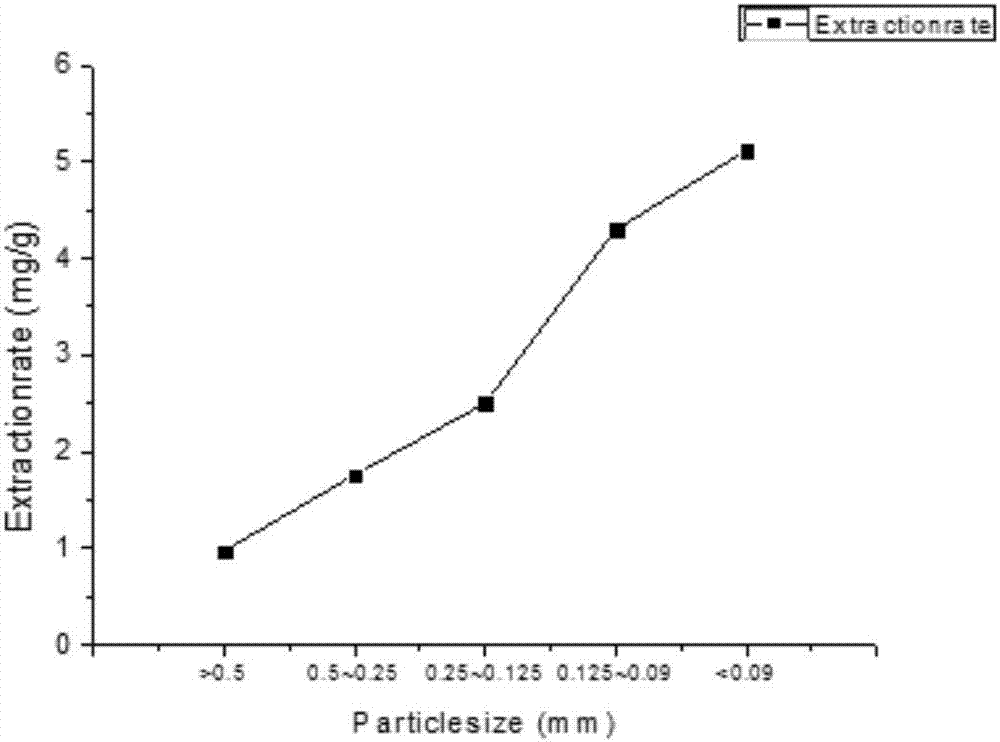

[0047] Pretreatment: Wash the brown algae to remove sediment, freeze-dry and pulverize, the particle size is 0.09-0.125mm.

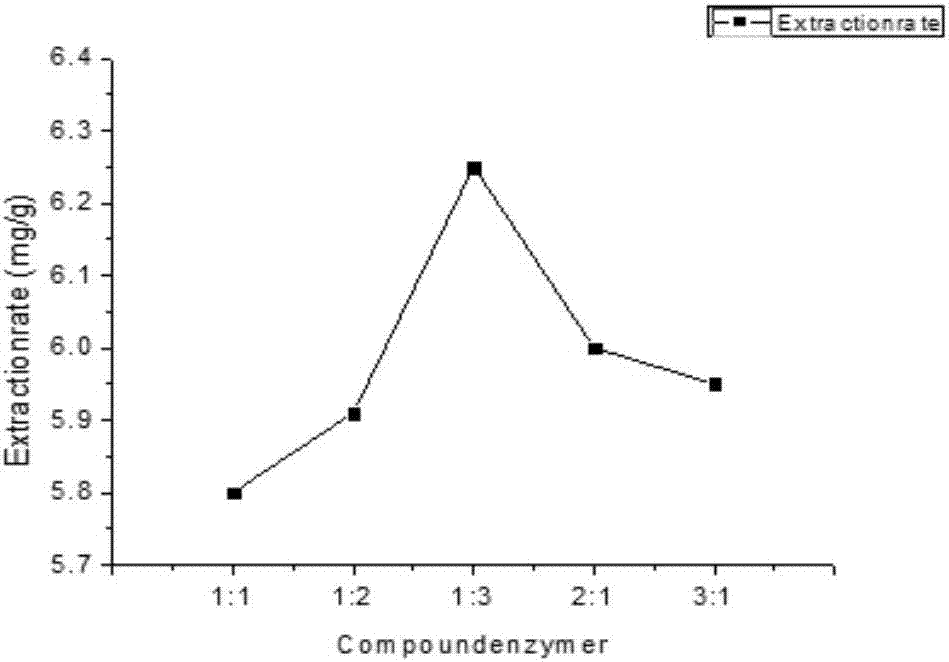

[0048] Compound enzyme preparation: pectinase: cellulase=1:3.

[0049] Extraction: Mix the pretreated brown algae powder and compound enzyme, add ethanol and stir, then send it into the microwave chamber, low-temperature microwave co-extraction, the microwave temperature is 45°C, and the microwave time is 4min (extraction times are 3 times, respectively extracting 1min, 2min, 1min).

[0050] Separation: After microwave, solid-liquid separation is carried out, and the liquid phase is filtered through a 0.45um membrane to remove impurities, and then freeze-dried to obtain fucoxanthin.

Embodiment 2

[0052] A method for extracting fucoxanthin from brown algae provided in this embodiment comprises:

[0053] Pretreatment: Wash the brown algae to remove sediment, freeze-dry and pulverize, the particle size is 0.15-0.25mm.

[0054] Compound enzyme preparation: pectinase: cellulase=2:1.

[0055] Extraction: Mix the pretreated brown algae powder and compound enzyme, add ethanol and stir, then send it to the microwave chamber, low-temperature microwave co-extraction, the microwave temperature is 40°C, and the microwave time is 8 minutes (the number of extractions is 4 times, each time 2 minutes) . Among them, the mass ratio of brown algae powder and compound enzyme is 20:3, and the solid-liquid ratio of brown algae powder and ethanol is 1:30g / mL.

[0056] Separation: After microwave, solid-liquid separation is carried out, and the liquid phase is filtered through a 0.45um membrane to remove impurities, and then freeze-dried to obtain fucoxanthin.

Embodiment 3

[0058] A method for extracting fucoxanthin from brown algae provided in this embodiment comprises:

[0059] Pretreatment: Wash the brown algae to remove sediment, freeze-dry and pulverize, the particle size is 0.15-0.25mm.

[0060] Compound enzyme preparation: pectinase: cellulase = 1:1.

[0061] Extraction: Mix the pretreated brown algae powder and compound enzyme, add ethanol and stir, and then send it to the microwave room for low-temperature microwave co-extraction, the microwave temperature is 55°C, and the microwave time is 6min (extraction times are 4 times, each 1.5min ). Wherein, the mass ratio of brown algae powder and compound enzyme is 20:1, and the solid-liquid ratio of brown algae powder and ethanol is 1:20g / mL.

[0062] Separation: After microwave, solid-liquid separation is carried out, and the liquid phase is filtered through a 0.45um membrane to remove impurities, and then freeze-dried to obtain fucoxanthin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com