Method for electro-deposition of zinc in alkaline zincate solution

A technology of alkaline zincic acid and zincate, applied in the field of electrodeposition, can solve the problems of poor density of deposited zinc coating, easy passivation of coating, poor depth capability, etc., so as to increase the efficiency of zinc electrodeposition, facilitate industrialization, and reduce The effect of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

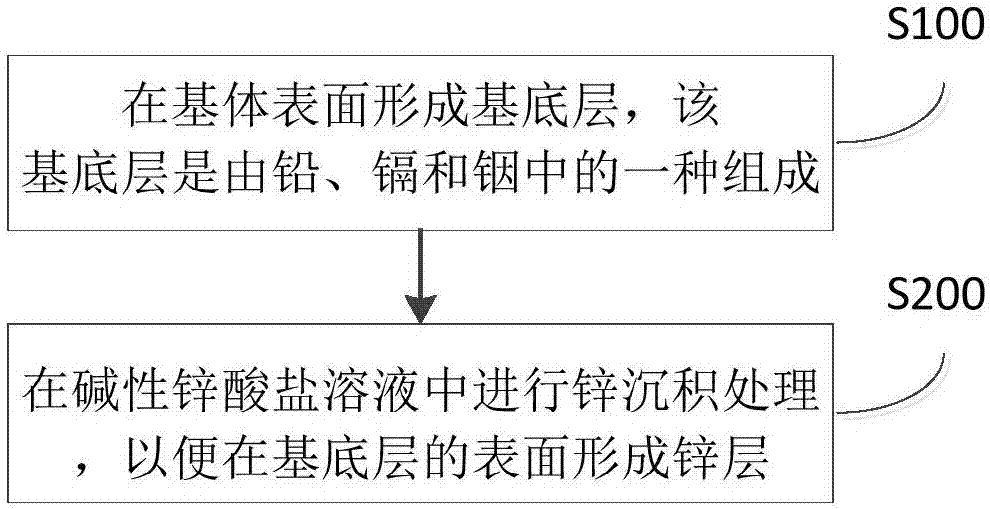

Method used

Image

Examples

Embodiment 1

[0051] In this embodiment, the method of electrodepositing zinc in an alkaline zincate solution is adopted, and a lead base layer is firstly applied on the surface of the nickel mesh, followed by zinc deposition. Specific steps are as follows:

[0052] (1) Nickel mesh is chemically removed from surface oil, and then the surface of nickel mesh is rinsed with water;

[0053] (2) carry out the electroplating process with the nickel net of pretreatment as negative electrode, wherein, be in the lead plating electrolyte that 110g / L hydrofluoric acid, 100g / L boric acid, 110g / L lead oxide and 0.2g / L gelatin form, And the pH of the electrolyte=1~2, at room temperature, at 40mA / cm 2 The current density, the anode is a pure lead sheet, the distance between the anode and the cathode is 5cm, and the electroplating time is 1h, that is, a layer of lead plating with better density is obtained on the surface of the nickel mesh.

[0054] (3) Dissolve 150g / L KOH and 50g / L LiOH in a certain vol...

Embodiment 2

[0058] In this embodiment, the method of electrodepositing zinc in an alkaline zincate solution is adopted, and a base layer of cadmium is firstly applied on the surface of the copper mesh, and then zinc is deposited. Specific steps are as follows:

[0059] (1) Remove surface oil stains from the copper mesh by chemical method, and then rinse the surface of the copper mesh with water;

[0060] (2) Carry out electroplating treatment with the pretreated copper net as cathode, wherein, be the cadmium plating of 60g / L cadmium sulfate, 120g / L ammonium chloride, 40g / L ethylenediaminetetraacetic acid and thiourea 1g / L composition In the electrolyte, and the pH of the electrolyte = 6, at room temperature, at 10mA / cm 2 The current density is high, the anode is a pure graphite sheet, the distance between the anode and the cathode is 5cm, and the electroplating time is 20min, that is, a layer of dense cadmium coating is obtained on the surface of the copper mesh.

[0061] (3) Dissolve 1...

Embodiment 3

[0065] In this embodiment, the method of electrodepositing zinc in an alkaline zincate solution is adopted, and an indium base layer is firstly applied on the surface of the nickel mesh, and then zinc is deposited. Specific steps are as follows:

[0066] (1) Nickel mesh is chemically removed from surface oil, and then the surface of nickel mesh is rinsed with water;

[0067] (2) The pretreated nickel mesh is used as the cathode for electroplating treatment, wherein, in the indium plating electrolyte composed of 40g / L indium sulfate and 15g / L sodium sulfate, at room temperature, at 10mA / cm 2 The current density is high, the anode is a pure graphite sheet, the distance between the anode and the cathode is 5cm, and the electroplating time is 1h, that is, a layer of indium coating with better density is obtained on the surface of the nickel mesh.

[0068] (3) Dissolve 200g / L KOH in a certain volume of distilled water, add 20g / L ZnO while hot, and add 20g / L K2CO3, 3g / L In3+ and 1g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com