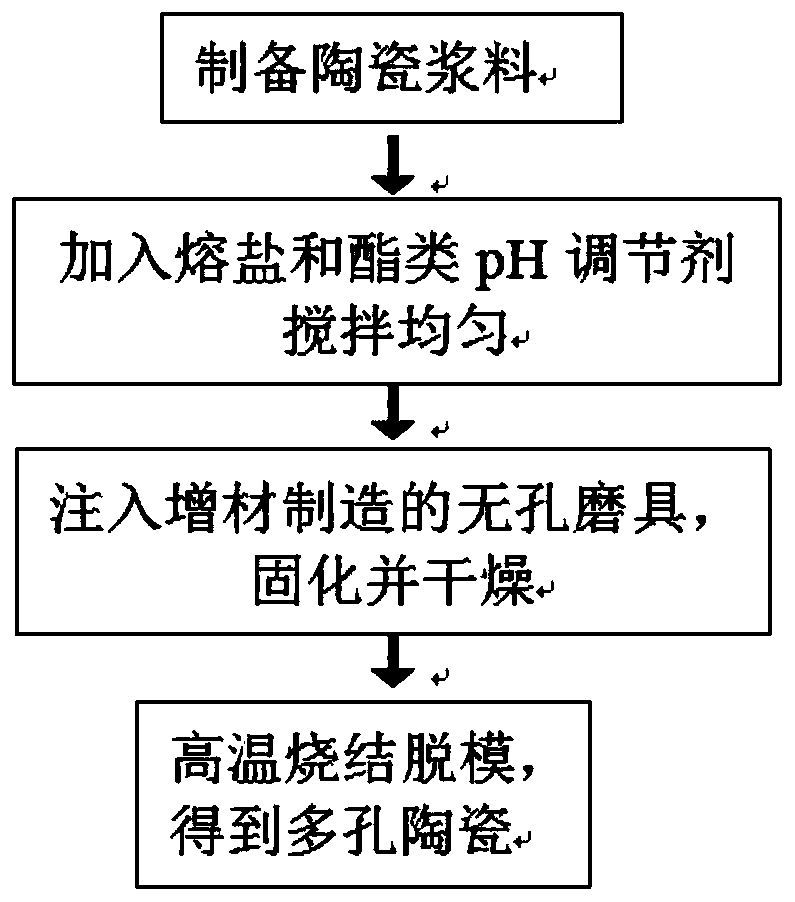

A preparation method of direct solidification injection molding of complex porous ceramics with high porosity

A technology of porous ceramics and high porosity, which is applied to ceramic products, other household utensils, household utensils, etc. It can solve the problems of difficult preparation of porous ceramics, high cost of mold preparation, and low strength of green body, so as to achieve good uniformity and avoid The effect of low strength and lower sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

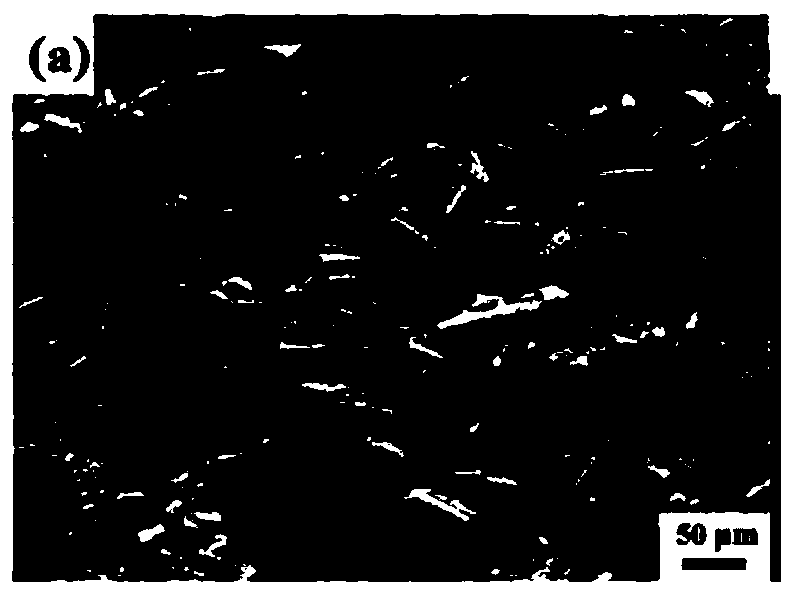

[0043] 2.5vol% glyceryl diacetate solidified 0.2wt% ammonium citrate dispersed 45vol% alumina fiber slurry containing 40wt% potassium sulfate, the alumina fiber length was 90 μm, and the aspect ratio was 4.

[0044] Mix 100g of alumina fiber, 0.2g of ammonium citrate and 31.3g of deionized water, and ball mill for 150min at a ball milling speed of 250r / min to obtain a ceramic slurry with a solid phase volume fraction of 45vol% negatively charged on the surface, and then add 40g After potassium sulfate, continue ball milling at a rate of 250r / min for 20min, then add 0.78ml of glycerol diacetate, stir with a glass rod for 45s, pour it into a nylon mold prepared by selective laser sintering technology, place it at 85°C for 12h, and then place it in a sintering furnace In the process, the temperature was first raised to 400°C at 3°C / min and held for 4 hours, and then the temperature was raised to 1450°C at 10°C / min and held for 2 hours to obtain a high-porosity full-fiber complex a...

Embodiment 2

[0047] 0.5vol% triacetin solidified 1.0wt% ammonium polyacrylate dispersed 25vol% zirconia fiber slurry containing 5wt% sodium sulfate, the zirconia fiber length was 10 μm, and the aspect ratio was 3.

[0048] Mix 100g of zirconia fiber, 1g of ammonium polyacrylate and 50.9g of deionized water, and ball mill for 50min at a ball milling speed of 400r / min to prepare a ceramic slurry with a solid phase volume fraction of 25vol% negatively charged on the surface, and then add 5g of sulfuric acid After sodium, continue ball milling at a rate of 300r / min for 10min, then add 0.26ml triacetin, stir with a glass rod for 15s, inject it into a photosensitive resin mold prepared by photocuring molding technology, place it at 45°C for 24h, and then place it in a sintering furnace In the process, the temperature was first raised to 600°C at 3°C / min for 2 hours, and then the temperature was raised to 1500°C at 8°C / min for 6 hours to obtain a high-porosity full-fiber complex zirconia ceramic s...

Embodiment 3

[0050] 1.5vol% ethyl lactate solidified 0.5wt% sodium tripolyphosphate dispersed 30vol% silicon nitride fiber slurry containing 20wt% potassium sulfate, the silicon nitride fiber length was 50 μm, and the aspect ratio was 5.

[0051] 100g of silicon nitride fiber, 0.5g of sodium tripolyphosphate and 68.6g of deionized water were mixed, and ball milled for 80min at a ball milling speed of 300r / min to obtain a ceramic slurry whose solid phase volume fraction was 30vol% negatively charged on the surface, and then After adding 20g of potassium sulfate, continue ball milling at a rate of 400r / min for 10min, then add 1.03ml of ethyl lactate, stir with a glass rod for 20s, pour it into a coated sand mold prepared by 3D printing technology, place it at 75°C for 16h, and then place it in In the nitrogen atmosphere sintering furnace, first raise the temperature at 5°C / min to 800°C for 3 hours, then raise the temperature at 8°C / min to 1750°C for 4 hours to obtain a high-porosity full-fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com