Dielectric medium of ceramic capacitor and preparation process thereof

A technology of ceramic capacitors and dielectrics, which is applied in the direction of fixed capacitor dielectrics and components of fixed capacitors, etc. It can solve the problems of unsatisfactory dielectric constant and voltage resistance, high sintering temperature, small dielectric constant, etc., and achieve performance stability Good, low sintering temperature, high dielectric constant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

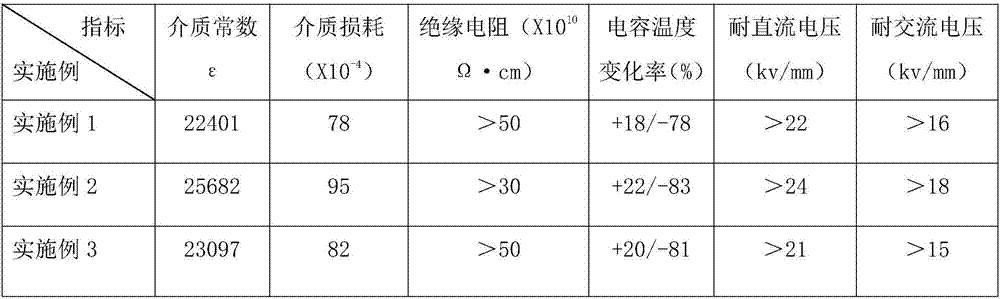

Examples

Embodiment 1

[0026] A dielectric for ceramic capacitors comprising the following raw materials: BaTiO 3 40kg, SrTiO 3 10kg, BaZrO 3 10kg, CaTiO 3 8kg, MgNb2 o 5 8kg, CeO 2 2kg, ZnO 2kg, Co 2 o 3 2kg, BaSiO 3 1kg, Gd 2 o 3 1kg.

[0027] Among them, the BaTiO 3 It is prepared by the following process: the conventional chemical raw material BaCO 3 and TiO 2 According to the molar ratio of 1:1, grind and mix evenly, put it in an alumina crucible and keep it at 1100°C for 100 minutes, and synthesize BaTiO by solid state reaction 3 , after cooling, grind through a 150-mesh sieve, and set aside.

[0028] The SrTiO 3 It is prepared by the following process: the conventional chemical raw material SrCO 3 and TiO 2 According to the molar ratio of 1:1, grind and mix evenly, put it into an alumina crucible and keep it at 1120°C for 100 minutes, and synthesize SrTiO by solid state reaction 3 , after cooling, grind through a 150-mesh sieve, and set aside.

[0029] The BaZrO 3 It is pre...

Embodiment 2

[0038] A dielectric of a ceramic capacitor comprising the following raw materials: BaTiO 3 50kg, SrTiO 3 15kg, BaZrO 3 15kg, CaTiO 3 10kg, MgNb 2 o 5 10kg, CeO 2 3kg, ZnO 3kg, Co 2 o 3 3kg, BaSiO 3 2kg, Gd 2 o 3 2kg.

[0039] Among them, the BaTiO 3 It is prepared by the following process: the conventional chemical raw material BaCO 3 and TiO 2 According to the molar ratio of 1:1, grind and mix evenly, put it in an alumina crucible and keep it at 1160°C for 125 minutes, and synthesize BaTiO by solid state reaction 3 , after cooling, grind through a 200-mesh sieve, and set aside.

[0040] The SrTiO 3 It is prepared by the following process: the conventional chemical raw material SrCO 3 and TiO 2 According to the molar ratio of 1:1, grind and mix evenly, put it in an alumina crucible and keep it at 1160°C for 120 minutes, and synthesize SrTiO by solid state reaction 3 , after cooling, grind through a 200-mesh sieve, and set aside.

[0041] The BaZrO 3 It is p...

Embodiment 3

[0050] A dielectric of a ceramic capacitor comprising the following raw materials: BaTiO 3 60kg, SrTiO 3 20kg, BaZrO 3 20kg, CaTiO 3 12kg, MgNb 2 o 5 12kg, CeO 2 4kg, ZnO 4kg, Co 2 o 3 4kg, BaSiO 3 3kg, Gd 2 o 3 3kg.

[0051] Among them, the BaTiO 3 It is prepared by the following process: the conventional chemical raw material BaCO 3 and TiO 2 According to the molar ratio of 1:1, grind and mix evenly, put it in an alumina crucible and keep it at 1220°C for 130 minutes, and synthesize BaTiO by solid state reaction 3 , after cooling, grind through a 250-mesh sieve and set aside.

[0052] The SrTiO 3 It is prepared by the following process: the conventional chemical raw material SrCO 3 and TiO 2 According to the molar ratio of 1:1, grind and mix evenly, put it into an alumina crucible and keep it at 1200°C for 140 minutes, and synthesize SrTiO by solid state reaction 3 , after cooling, grind through a 250-mesh sieve and set aside.

[0053] The BaZrO 3 It is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com