Temperature-variation and light-dimming fireproof material, temperature-control and sun-shading fireproof glass and preparation method of temperature-control and sun-shading fireproof glass

A fire-resistant material and dimming technology, applied in chemical instruments and methods, glass/slag layered products, lamination, etc., can solve the problems that fire-resistant glass does not have dimming function, does not have fire-proof function, etc., and achieves automatic adjustment of sunlight Transmittance, eliminating the sun's burning sensation, and improving the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

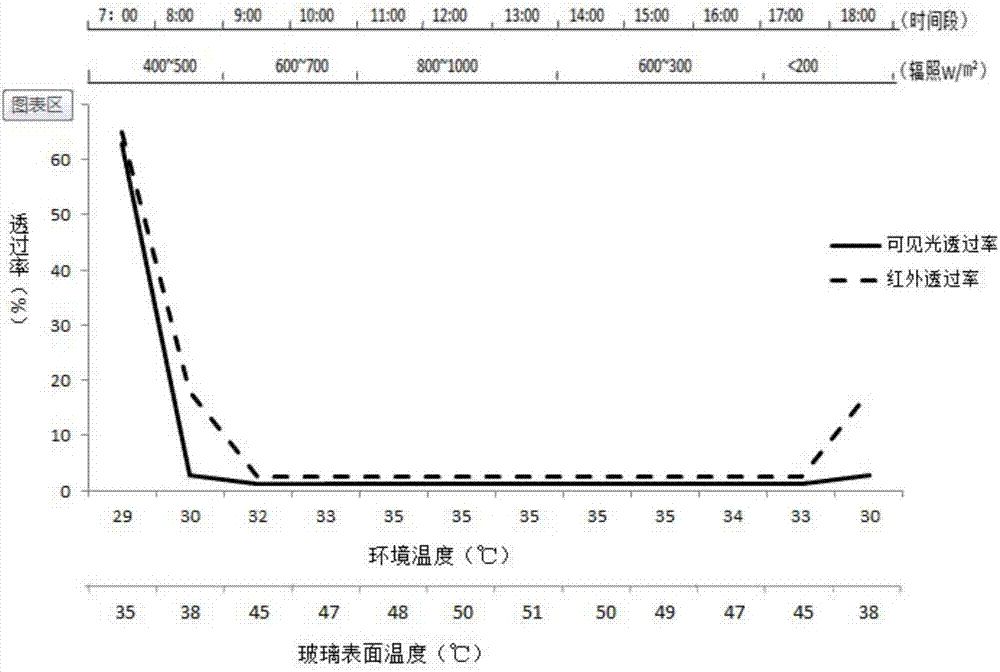

[0050] Example 1: Temperature-variable light-adjustable fireproof material, temperature-controlled light-shielding fireproof glass containing temperature-variable light-adjustable fireproof material and its preparation method

[0051] The composition of the temperature-changing light-adjusting fireproof material of this embodiment is as shown in Table 2:

[0052] Table 2: Components of the temperature-changing dimming fireproof material in this example

[0053] materials

parts by weight

Block polyether HLB=12.0

3

Hydroxyethyl Acrylate

1.5

polyethylene glycol diacrylate

0.5

4-Phenyl-benzophenone

0.5

0.01

Polyethylene glycol 600

25

0.3

40%wt nano silicon solution

30

1

1

water

37.19

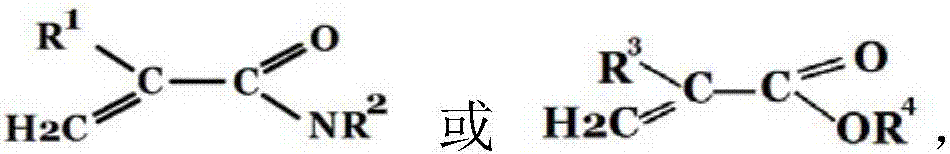

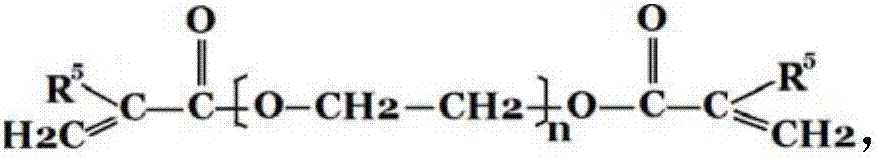

[0054] The preparation method of the temperature-changing light-adjusting fireproof material in thi...

Embodiment 2

[0069] Example 2: Temperature-variable light-adjustable fireproof material, temperature-controlled sunshade fireproof glass containing temperature-variable light-adjustable fireproof material and its preparation

[0070] The components of the temperature-changing light-adjusting fireproof material in this embodiment are as shown in Table 4:

[0071] Table 4: Components of the temperature-changing dimming fireproof material in this embodiment

[0072]

[0073]

[0074] The preparation method of the temperature-changing light-adjusting fireproof material has the following steps:

[0075] (1) Weighing all raw materials except cross-linked water-absorbing resin and water according to the ratio, and then putting them into a high-speed mixer and stirring for 40 minutes to obtain a mixture;

[0076] (2) Add cross-linked water-absorbing resin and water to the mixture obtained in step (1), and stir for 70 minutes to obtain the product.

[0077] The temperature-controlled sunsha...

Embodiment 3

[0081] Example 3: Temperature-variable light-adjustable fireproof material, temperature-controlled sunshade fireproof glass containing temperature-variable light-adjustable fireproof material and its preparation

[0082] The raw material components of the temperature-changing light-adjusting fireproof material in this embodiment are as shown in Table 6:

[0083] Table 6: Components of the temperature-changing dimming fireproof material in this embodiment

[0084] materials

parts by weight

Dodecylphenol polyoxyethylene ether HLB=14.5

10

10

Methoxypolyethylene glycol monoacrylate

5

0.01

0.01

Croscarmellose

0.5

Polypropylene Glycol 400

3.5

Potassium fluorosilicate

1

20%wt nano silicon solution

40

glucose

2

granulated sugar

3

2

water

22.98

[0085] The preparation method of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com