Method for inducing bionic calcification in collagen fibers through polymer polyelectrolyte, and applications thereof

A polyelectrolyte and collagen fiber technology, applied in tissue regeneration, pharmaceutical formulation, medical science, etc., to achieve the effects of enhanced mechanical strength, strong modifiability, and good internal environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Prepare 9mM CaCl with 10mM HEPES buffer as solvent 2 2H 2 O solution and 4.2mM K 2 HPO 4 solution, the above solutions were mixed isometrically to prepare a calcium phosphate solution (final concentration: 4.5mM CaCl 2 2H 2 O / 2.1mM K 2 HPO 4 );

[0045] (2) Polypropylene ammonium chloride (average molecular weight 150kDa) was dissolved in calcium phosphate solution at a ratio of 200ug / mL, and polypropylene ammonium chloride was prepared by utilizing the stabilizing effect of polypropylene ammonium chloride on supersaturated calcium phosphate solution Stable amorphous liquid phase calcium phosphate precursor solution.

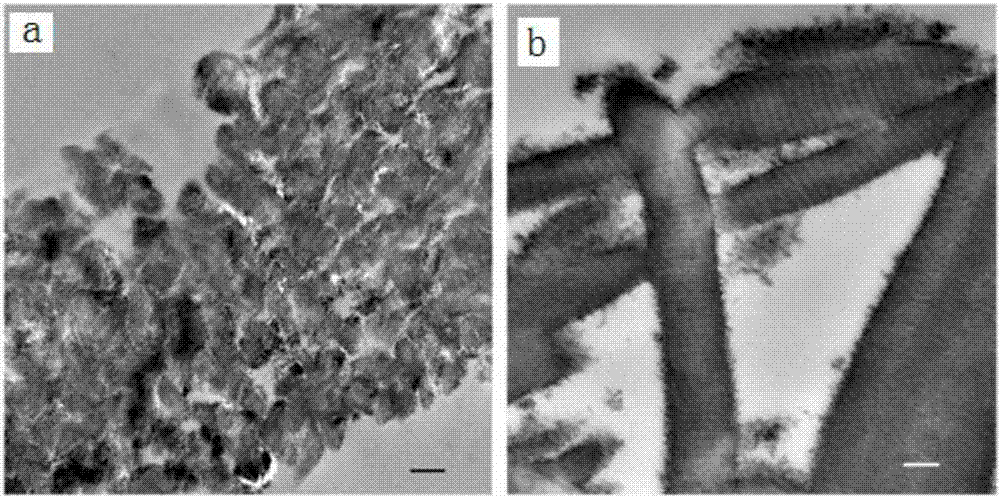

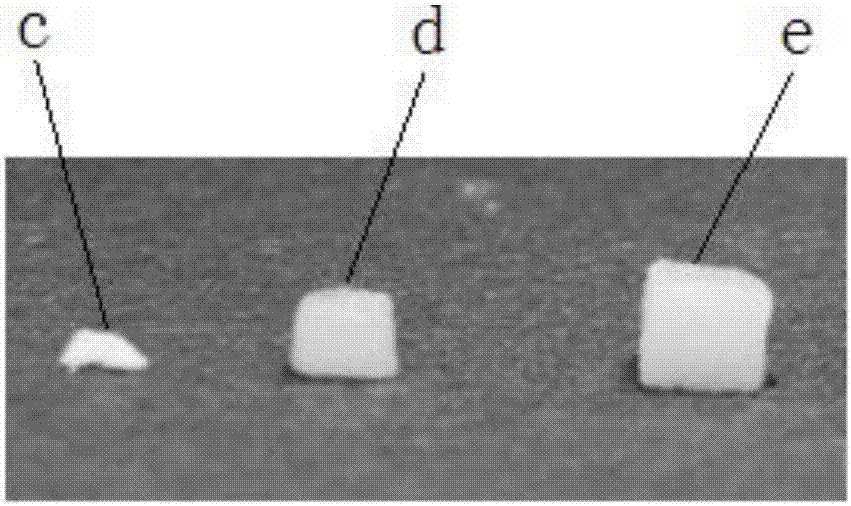

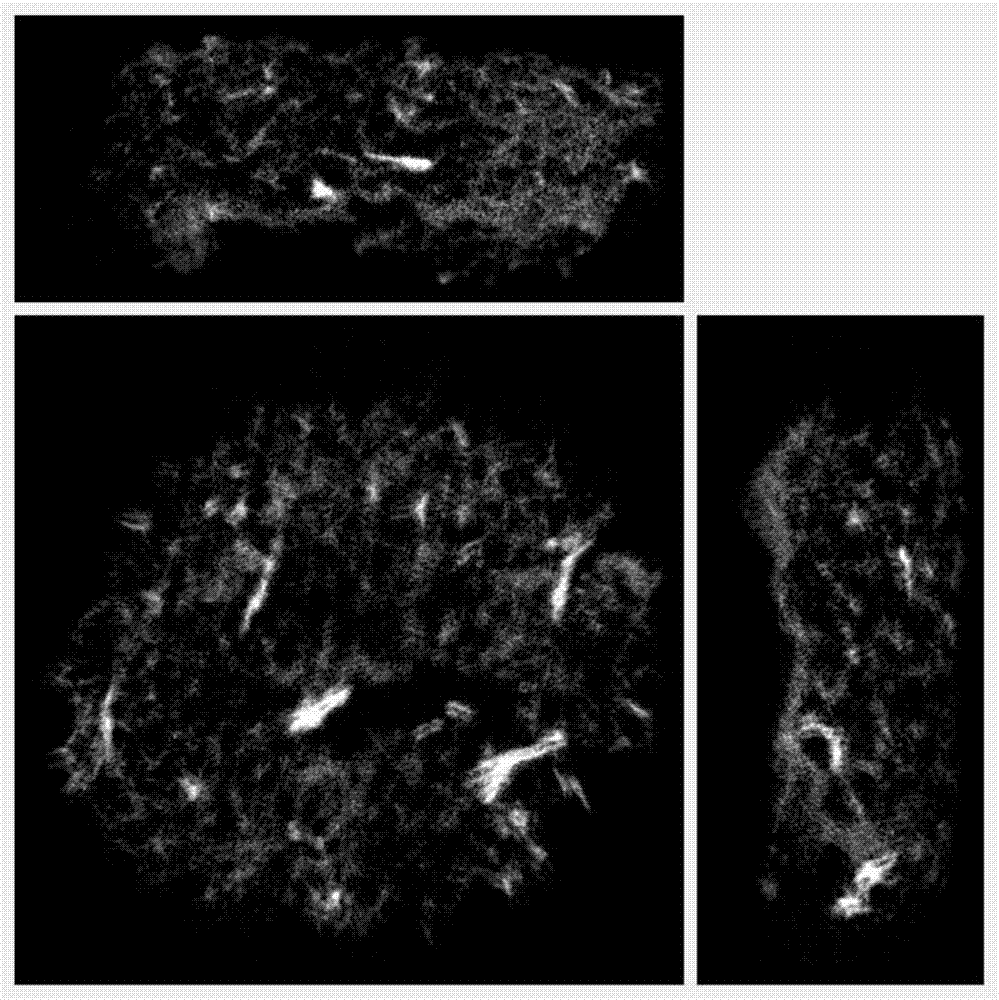

[0046] (3) Put the collagen sponge or the completely demineralized bone collagen matrix in the calcium phosphate mineralization solution stabilized by polypropylene ammonium chloride, incubate at a constant temperature of 37°C for 7 days, and replace it with fresh polypropylene ammonium chloride stabilized solution every day. The calcium phosp...

Embodiment 2

[0060] This embodiment differs from Embodiment 1 in that:

[0061](2) Polypropylene ammonium chloride (average molecular weight 150kDa) was dissolved in calcium phosphate solution at a ratio of 400 μg / mL, and polypropylene ammonium chloride was obtained by utilizing the stabilizing effect of polypropylene ammonium chloride on supersaturated calcium phosphate solution Stable amorphous liquid phase calcium phosphate precursor solution.

[0062] (3) Place the completely demineralized bone collagen in calcium phosphate mineralization solution stabilized by polypropylene ammonium chloride, incubate at a constant temperature of 37°C for 14 days, and replace with fresh calcium phosphate mineralization solution stabilized by polypropylene ammonium chloride every day , rinsed repeatedly with distilled water, and dried for later use, to prepare a biomimetic calcified bone collagen scaffold material within collagen fibers.

Embodiment 3

[0064] This embodiment differs from Embodiment 1 in that:

[0065] (2) Dissolve polypropylene ammonium chloride (average molecular weight 150kDa) in calcium phosphate solution at a ratio of 800 μg / mL, and use polypropylene ammonium chloride to stabilize the supersaturated calcium phosphate solution to obtain polypropylene ammonium chloride Stable amorphous liquid phase calcium phosphate precursor solution.

[0066] (3) Place the completely demineralized bone collagen in calcium phosphate mineralization solution stabilized by polypropylene ammonium chloride, incubate at a constant temperature of 37°C for 14 days, and replace with fresh calcium phosphate mineralization solution stabilized by polypropylene ammonium chloride every day , rinsed repeatedly with distilled water, and dried for later use, to prepare a biomimetic calcified bone collagen scaffold material within collagen fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com