Efficient chemical fiber textile dyeing wastewater recycling treatment system

A technology for dyeing wastewater and treatment system, which is applied in textile industry wastewater treatment, water/sewage treatment, water/sewage treatment equipment, etc. problem, to achieve the effect of fast output and small impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

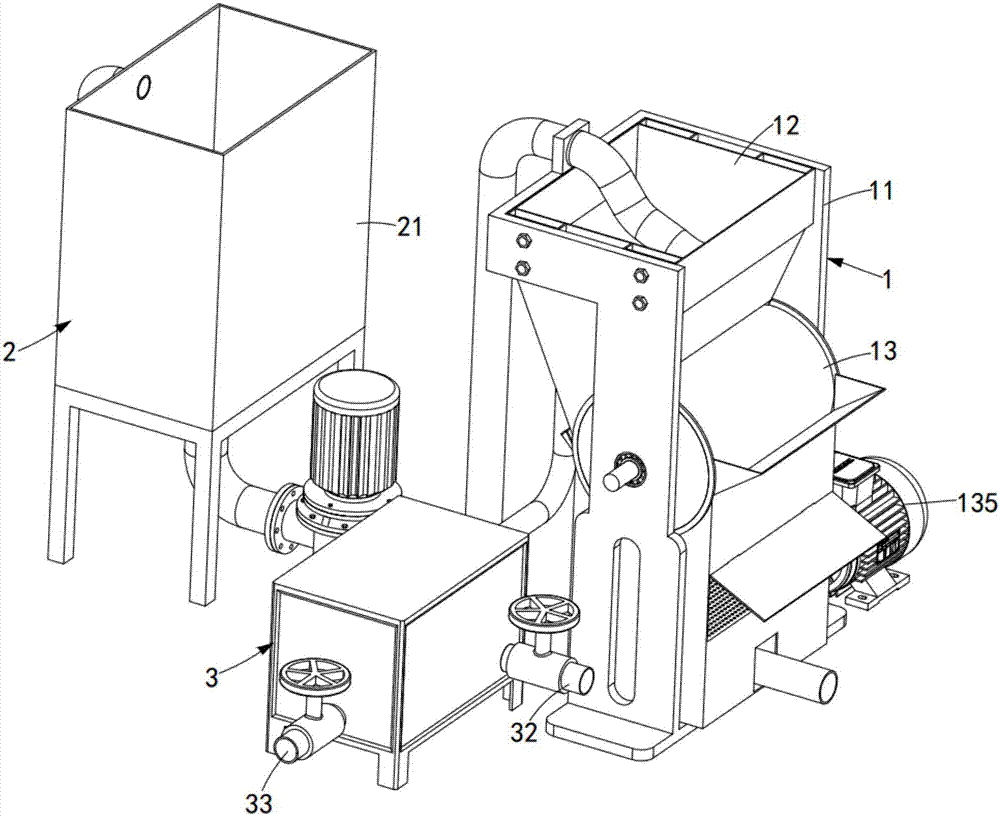

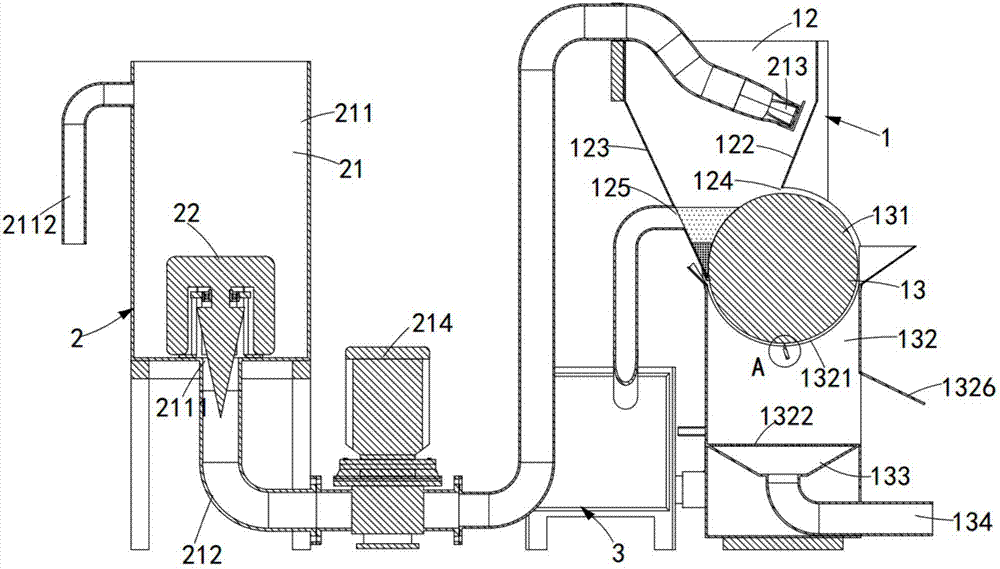

[0052] Such as figure 1 , figure 2 and image 3 As shown, a high-efficiency recycling chemical fiber textile dyeing wastewater treatment system includes:

[0053] Wastewater treatment mechanism 1, said wastewater treatment mechanism 1 is used for sludge separation and treatment of wastewater, which includes a mounting frame 11, a treatment bin 12 mounted on the top of the mounting frame 11, and a processing assembly mounted on the bottom of the mounting frame 11 13, and the processing chamber 12 is located directly above the processing assembly 13;

[0054] A waste water supply mechanism 2, the waste water supply mechanism 2 is located on one side of the waste water treatment mechanism 1, communicated with the treatment component 13, and includes a water supply component 21 and a stirring component 22 arranged inside the water supply component 21;

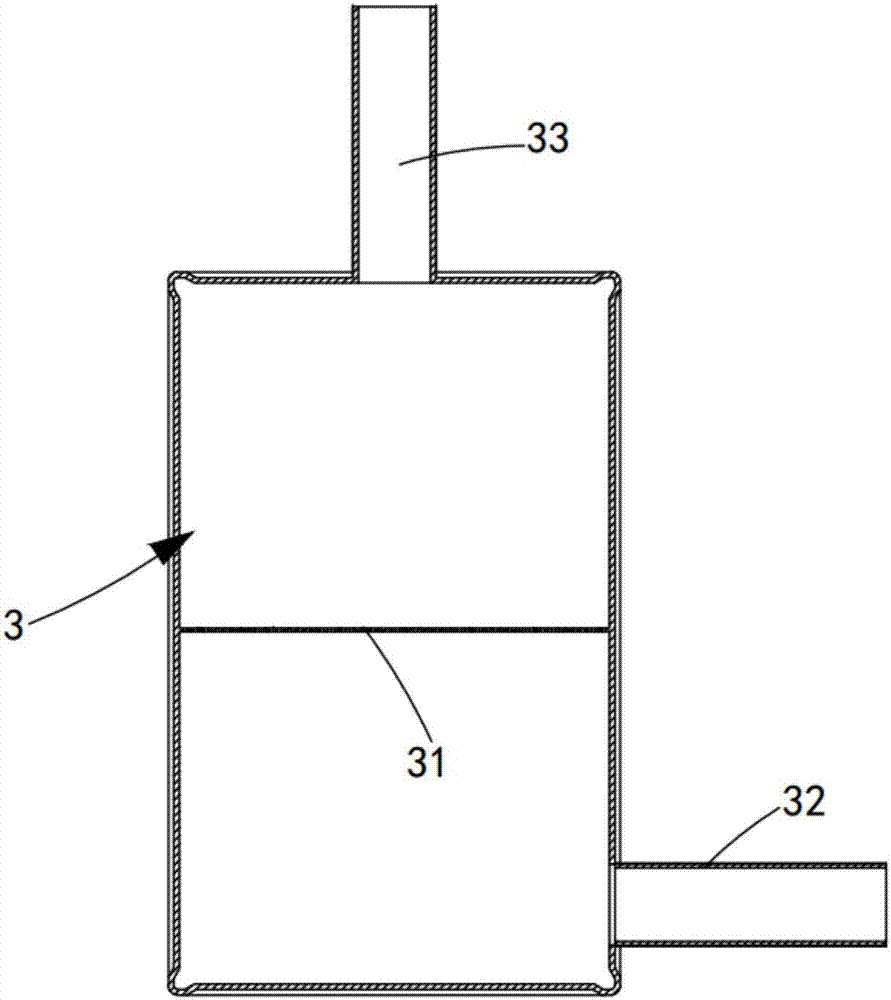

[0055] A waste water reuse tank 3, the waste water reuse tank 3 is located between the waste water treatment mechanism 1 and ...

Embodiment approach

[0059] Such as figure 2 As a preferred implementation manner, the processing component 13 includes:

[0060] Separation roller 131, the separation roller 131 is located directly below the processing chamber 12, it is arranged concentrically with the separation part 121, and its two ends are rotatably arranged on the installation frame 11;

[0061] A sludge box 132, the sludge box 132 is located directly below the separation roller 131, it is detachably connected to the installation frame 11, and its top is provided with a semicircular opening 1321, the semicircular opening 1321 is arranged concentrically with the separation roller 131, and a water filter 1322 is arranged at the bottom thereof;

[0062] A waste water bucket 133, the waste water bucket 133 is connected to the bottom of the sludge tank 132, which is conical and has a water outlet at the bottom;

[0063] Filtered water output pipe 134, the filtered water output pipe 134 is located at the bottom of the waste wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com