Hierarchical porous composite molecular sieve with adjustable acidity distribution and preparation method thereof

A composite molecular sieve and acidic technology, applied in the recovery/refining of mineral wax, crystalline aluminosilicate zeolite, hydrocarbon oil cracking, etc., to achieve the effect of improving product performance, excellent catalytic performance, and high adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

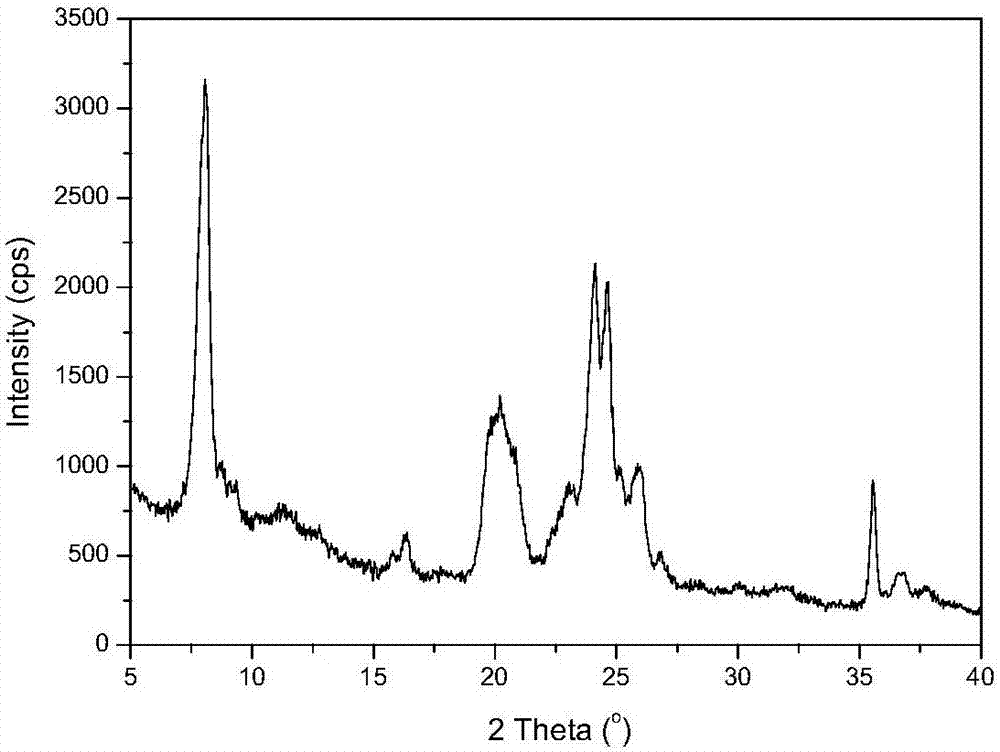

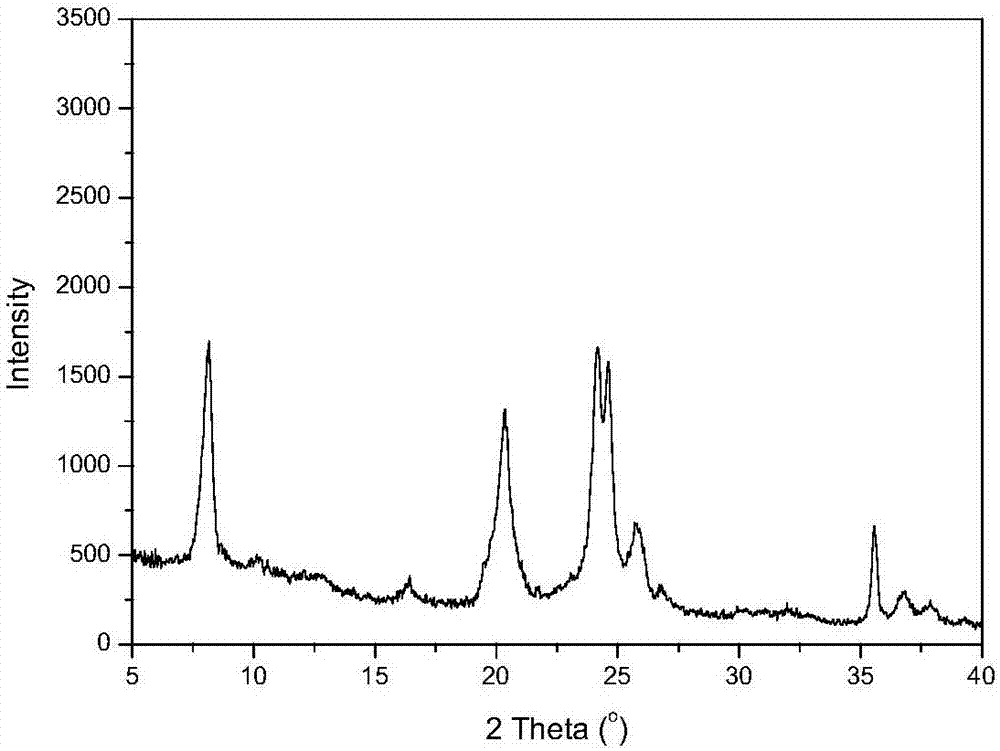

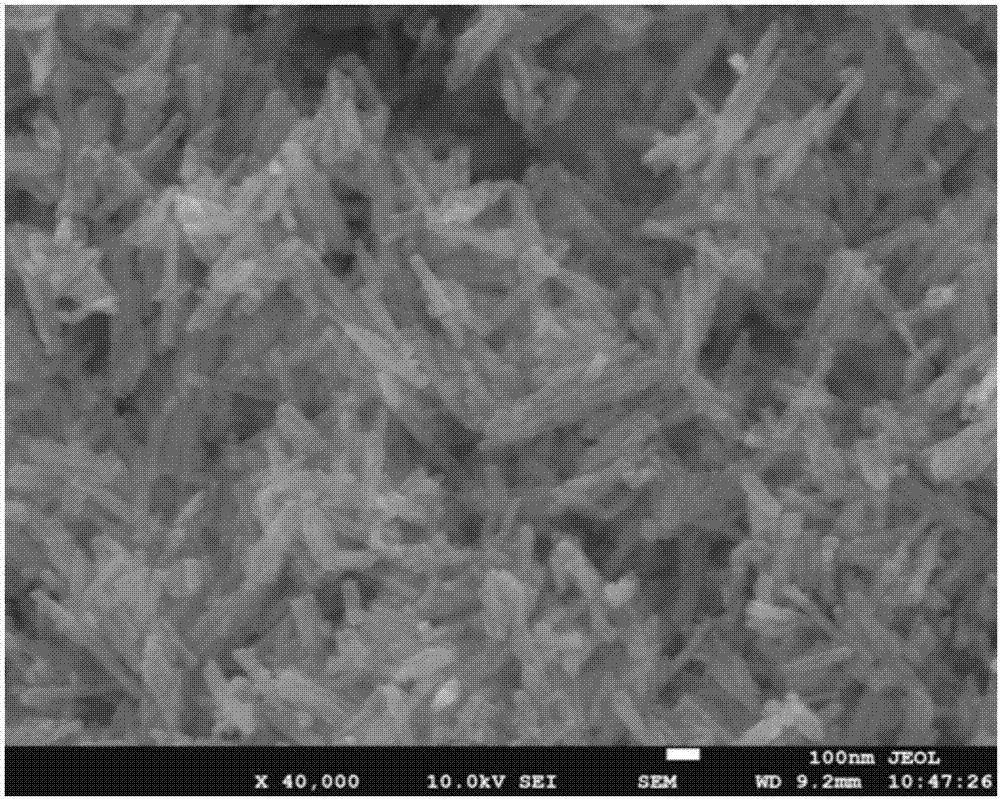

Embodiment 1

[0033] Add potassium hydroxide to deionized water, stir to dissolve completely, add ethylmethylamine and sodium aluminate successively, continue to stir until the mixture is completely dissolved, then add dimethylamine and silica sol in order to form the first Parts initial gel mixture (silicon source is SiO 2 In terms of aluminum source as Al 2 o 3 In terms of alkali source in OH - meter), SiO 2 :Al 2 o 3 : Ethylmethylamine: Dimethylamine: OH - : The molar ratio of deionized water=1:0.2:0.05:5.0:0.005:10.0; the first initial gel mixture obtained was transferred to a crystallization kettle, and after crystallization at 140°C and autogenous pressure for 48h, The solid product is separated by filtration, washed with deionized water until neutral, and dried to obtain the initial powder of composite silica-alumina molecular sieve; according to the raw material SiO 2 :Al 2 o 3 : Template A: Template B: OH - : The molar ratio of deionized water=1:0.2:0.025:2.5:0.005:10.0 t...

Embodiment 2

[0035] Add potassium hydroxide to deionized water, stir to dissolve completely, then add diethylamine and pseudoboehmite successively, continue stirring until the mixture is completely dissolved, then add dimethylformamide, n-propylamine and silica gel in order to form The first part of initial gel mixture (silicon source with SiO 2 In terms of aluminum source as Al 2 o 3 In terms of alkali source in OH - meter), SiO 2 :Al 2 o 3 : Diethylamine: Dimethylformamide + n-Propylamine: OH - : The molar ratio of deionized water = 1: 0.1: 0.1: 4.0 (the molar ratio of dimethylformamide: n-propylamine = 1: 1): 0.01: 30.0; transfer the obtained first initial gel mixture into In the crystallization kettle, after crystallization at 145°C and autogenous pressure for 48 hours, the solid product was separated by filtration, washed with deionized water until neutral, and dried to obtain the initial powder of composite silicon-aluminum molecular sieve; according to the ratio of raw materia...

Embodiment 3

[0037] Add potassium hydroxide to deionized water, stir to dissolve completely, add 1,6-hexamethylenediamine, aluminum chloride successively, continue to stir until the mixture is completely dissolved, then add isopropylamine, methyl orthosilicate and orthosilicate in order ethyl ester to form the first initial gel mixture with the following molar ratio (silicon source is SiO 2 In terms of aluminum source as Al 2 o 3 In terms of alkali source in OH - meter), SiO 2 :Al 2 o 3 : 1,6-hexanediamine: Isopropylamine: OH - : The molar ratio of deionized water = 1 (methyl orthosilicate: ethyl orthosilicate = 1:1, with SiO 2 molar ratio): 0.05: 0.2: 3.0: 0.02: 20.0; transfer the obtained first initial gel mixture into a crystallization kettle, crystallize at 150°C for 24 hours under autogenous pressure, and separate the solid product by filtration. Wash with deionized water until neutral, and dry to obtain the initial powder of composite silica-alumina molecular sieve; according ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com