A method for synthesizing noble metal nanoparticles using exopolysaccharide of Lactobacillus plantarum

A technology of Lactobacillus plantarum and extracellular polysaccharides, which is applied in the fields of biotechnology and nanomaterials, can solve the problems of energy consumption, environmental pollution, and time-consuming synthesis of precious metal nanoparticles, and achieve safe and harmless raw material sources, uniform size distribution, and reduced The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of embodiment 1 exopolysaccharide

[0035] A sample of Lactobacillus plantarum LCC-605 was taken and activated three times with MRS medium. Centrifuge at 14000g for 30min at 4°C to remove bacteria. After centrifugation, pour the upper clear night into a beaker, and centrifuge the remaining cells again, pour the upper clear night into the beaker again, and then pour 80% trichloroacetic acid into the beaker until the final concentration of trichloroacetic acid is 4%. Refrigerate overnight at 4°C to precipitate protein. The next day, the solution in the beaker was centrifuged again to separate the precipitated protein. Remove the precipitate, pour out the supernatant, then add three times the volume of absolute ethanol, and put it in a refrigerator at 4°C overnight to precipitate the exopolysaccharide. The next day, centrifuge the solution in the beaker to precipitate polysaccharides. Take out the polysaccharide and add a small amount of ultrapur...

Embodiment 2

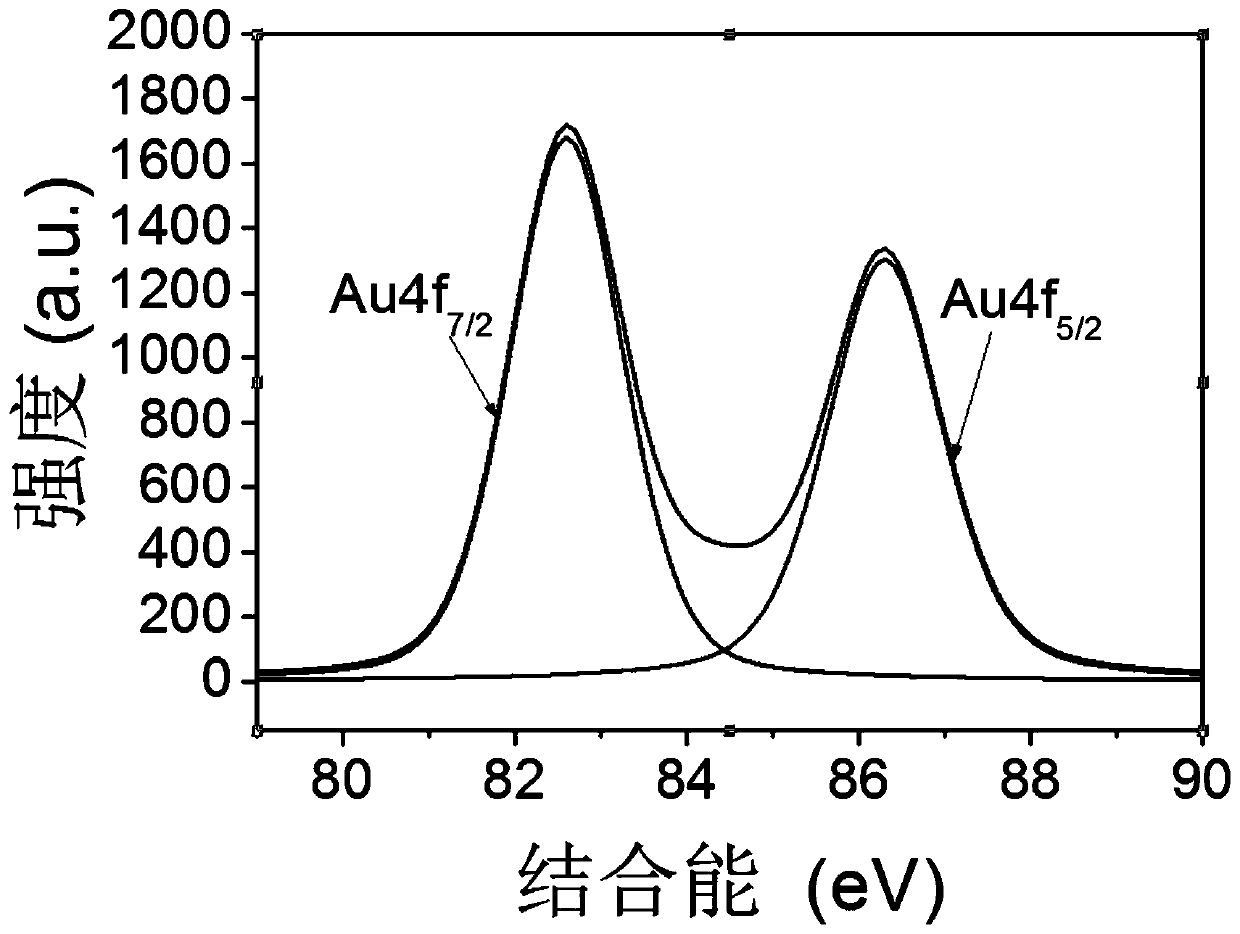

[0036] Example 2 Exopolysaccharide Synthesis of Noble Metal Nanoparticles

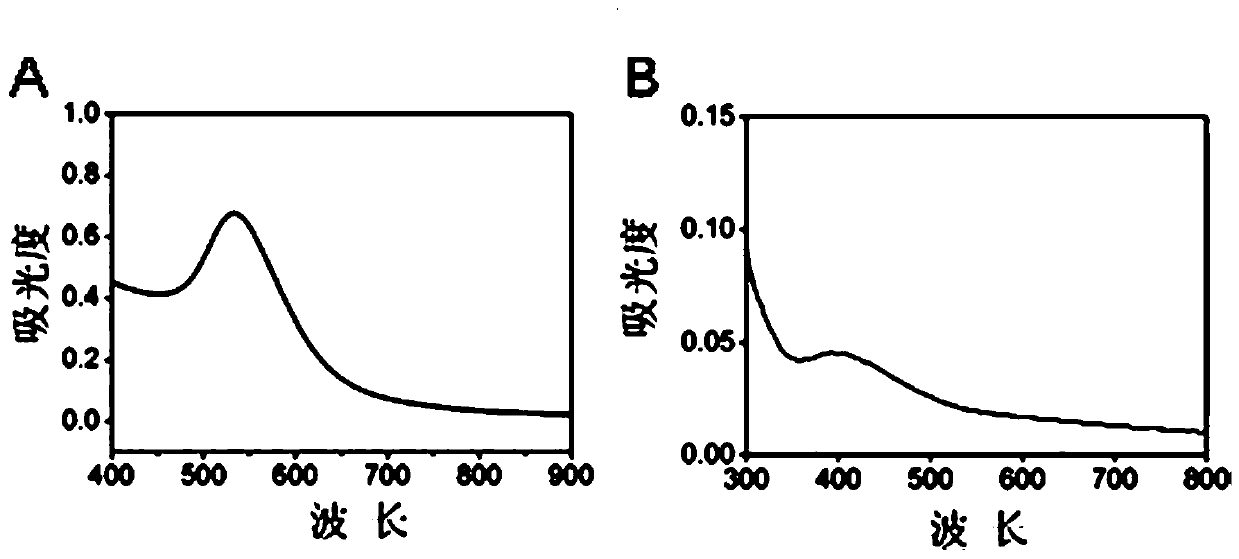

[0037] Make exopolysaccharide into a 2mg / mL solution, take 5mL and add it to 50mL 100mg / L chloroauric acid solution or silver nitrate solution, and boil. Samples were taken for analysis at 0, 3, 10, 15 and 30 minutes, respectively. see results figure 1 , Wine red appeared in the chloroauric acid polysaccharide solution at 15 minutes, which is the characteristic color of gold nanoparticles, indicating that gold nanoparticles were synthesized after 15 minutes of reaction.

Embodiment 3

[0038] Example 3 Exopolysaccharide Synthesis of Noble Metal Nanoparticles

[0039] Make exopolysaccharide into a 0.2mg / mL solution, take 5mL and add it to 25mL 10mg / L chloroauric acid solution or silver nitrate solution, react at 25°C for 40min and take samples for analysis.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com