Improved low-smoke halogen-free cable rubber jacket and preparation method thereof

A technology for cables and rubber sleeves, applied in the field of improved low-smoke halogen-free cable rubber sleeves and their preparation, can solve problems such as limited improvement effect, and achieve the effects of good oxidation resistance, stable chemical properties and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

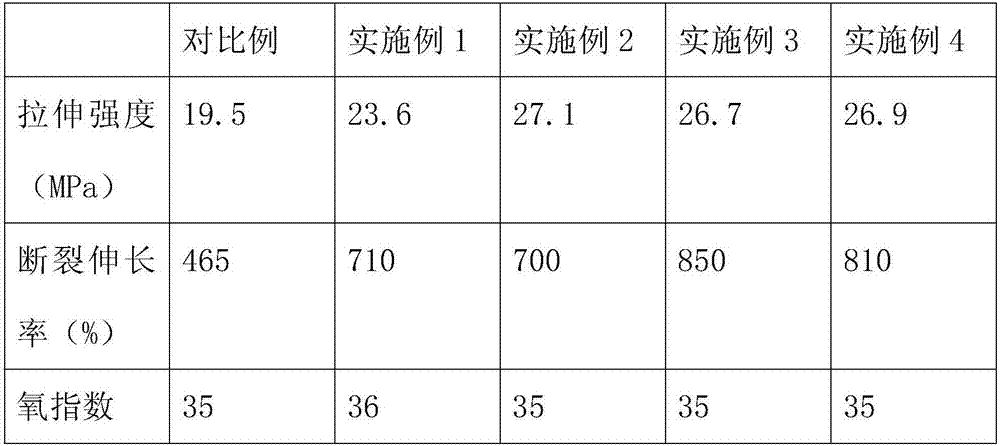

Examples

Embodiment 1

[0023] A method for preparing an improved low-smoke halogen-free cable rubber sleeve, comprising the following steps:

[0024] The following parts are parts by weight,

[0025] A. Use the raw materials of the following components to prepare the cable inner sleeve,

[0026] 250 parts of EPDM rubber, 440 parts of methyl vinyl silicone rubber, 45 parts of 1,3-diethyl dicarboxylate, 20 parts of tetrabutyl ammonium hydrogen phosphate, 3 parts of dimethyl Urea, 3 parts of m-carborane, 27 parts of 3-methoxybenzyl alcohol, 15 parts of 3-nitro-4-aminophenol, 6 parts of calcium sulfate, 34 parts of carbon black, 12 parts of zirconium;

[0027] B. Use the raw materials of the following components to prepare the cable jacket,

[0028] 410 parts of polyethylene, 270 parts of EVA resin, 18 parts of disodium edetate, 4 parts of dicumyl peroxide, 1 part of triethanolamine, 55 parts of tert-butyl isosulfate, 13 parts of 3-nitro-4-methylacetophenone, 7 parts of potassium bisulfate, 45 parts...

Embodiment 2

[0039] A method for preparing an improved low-smoke halogen-free cable rubber sleeve, comprising the following steps:

[0040] The following parts are parts by weight,

[0041] A. Use the raw materials of the following components to prepare the cable inner sleeve,

[0042] 250 parts of EPDM rubber, 440 parts of methyl vinyl silicone rubber, 45 parts of 1,3-diethyl dicarboxylate, 20 parts of tetrabutyl ammonium hydrogen phosphate, 3 parts of dimethyl Urea, 3 parts of m-carborane, 27 parts of 3-methoxybenzyl alcohol, 15 parts of 3-nitro-4-aminophenol, 6 parts of calcium sulfate, 34 parts of carbon black, 12 parts of zirconium;

[0043] B. Use the raw materials of the following components to prepare the cable jacket,

[0044] 410 parts of polyethylene, 270 parts of EVA resin, 18 parts of disodium edetate, 4 parts of dicumyl peroxide, 1 part of triethanolamine, 55 parts of tert-butyl isosulfate, 13 parts of 3-nitro-4-methylacetophenone, 7 parts of potassium bisulfate, 45 parts...

Embodiment 3

[0055] A method for preparing an improved low-smoke halogen-free cable rubber sleeve, comprising the following steps:

[0056] The following parts are parts by weight,

[0057] A. Use the raw materials of the following components to prepare the cable inner sleeve,

[0058] 250 parts of EPDM rubber, 440 parts of methyl vinyl silicone rubber, 45 parts of 1,3-diethyl dicarboxylate, 20 parts of tetrabutyl ammonium hydrogen phosphate, 3 parts of dimethyl Urea, 3 parts of m-carborane, 27 parts of 3-methoxybenzyl alcohol, 15 parts of 3-nitro-4-aminophenol, 6 parts of calcium sulfate, 34 parts of carbon black, 12 parts of zirconium;

[0059] B. Use the raw materials of the following components to prepare the cable jacket,

[0060] 410 parts of polyethylene, 270 parts of EVA resin, 18 parts of disodium edetate, 4 parts of dicumyl peroxide, 1 part of triethanolamine, 55 parts of tert-butyl isosulfate, 13 parts of 3-nitro-4-methylacetophenone, 7 parts of potassium bisulfate, 45 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com