A kind of coated magnetic abrasive grain and its preparation method

A magnetic abrasive grain, coated technology, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problem that mechanical grinding is not directly applied, and achieve the effect of low cost, simple process and small particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

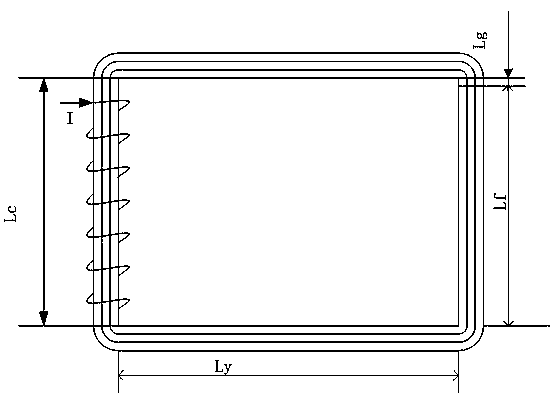

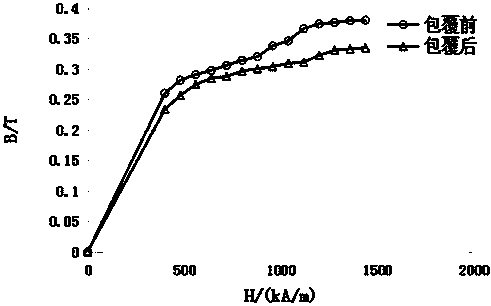

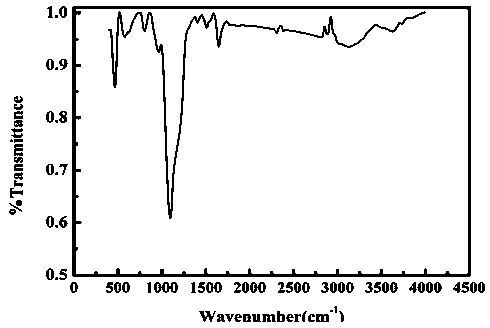

Image

Examples

Embodiment 1

[0030] The raw materials used in the embodiment are as follows:

[0031] The molar ratio of ferrous chloride and ferric chloride is 1:2 according to the iron ion; the molar ratio of Fe ion and ammonia water ammonium ion is 1:3, and the concentration is 25% ammonia water 90ml; ferric oxide: modifier The mass ratio is 1:3, weigh 1g of ferric oxide and 3g of sodium citrate modifier; add ethanol: water at a ratio of 1:5 to configure 60ml of ethanol-water solution; according to ethyl orthosilicate: The volume ratio of the solution is 1:20, add 3ml of tetraethyl orthosilicate; add 30ml of ammonia water at the ratio of ammonia water: solution volume ratio of 1:2, and add dropwise at a rate of 2 drops / second.

[0032] The preparation steps are as follows:

[0033] (1) Put the ferrous chloride and ferric chloride into the beaker according to the molar ratio of ferric ion as 1:2, weigh 8.57g of ferrous chloride and 11.6504g of ferric chloride respectively.

[0034] (2) Add 400ml of di...

Embodiment 2

[0050] A coated magnetic abrasive grain of the present invention is basically the same in composition and preparation process as the coated magnetic abrasive grain of Example 1, the difference is that the quality of ferrous chloride and ferric chloride in the step is selected as 7.95g and 16.22g, thus preparing ferric oxide with different particle sizes.

[0051] The preparation steps are as follows:

[0052] (1) Weigh ferrous chloride and ferric chloride according to the molar ratio of ferric ion as 1:1.5, respectively weigh 7.05g of ferrous chloride and 16.22g of ferric chloride into a beaker.

[0053] (2) Add 200ml of distilled water into the beaker, stir at a speed of 350r / min to disperse it evenly in the distilled water, make a solution with a certain concentration, and seal it with plastic wrap.

[0054] (3) Put the above solution on a constant temperature stirrer, adjust the speed to 300r / min, adjust the temperature to 50 degrees, and stir at constant temperature for a...

Embodiment 3

[0066] A coated magnetic abrasive grain of the present invention is basically the same in composition and preparation process as the coated magnetic abrasive grain of Example 1, the difference is that the quality of ferrous chloride and ferric chloride in the step is selected as 8.57g and 11.6504g, thus preparing ferric oxide with different particle sizes.

[0067] The preparation steps are as follows:

[0068] (1) Put ferrous chloride and ferric chloride into the beaker according to the molar ratio of ferric ion as 1:1.5, weigh 8.57g of ferrous chloride and 11.6504g of ferric chloride respectively.

[0069] (2) Add 400ml of distilled water to the beaker, stir at a speed of 400r / min to disperse it evenly in the distilled water, make a solution with a certain concentration, and seal it with plastic wrap.

[0070] (3) Put the above solution on a constant temperature stirrer, adjust the speed to 500r / min, adjust the temperature to 50 degrees, and stir at constant temperature for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com