Method for preparing nitrogen-doped graphene aerogel by simultaneously using SiO2-NH2 as template and nitrogen doping agent

A graphene airgel and graphene technology, applied in the direction of graphene, nano-carbon, hybrid capacitor electrodes, etc., can solve the problems of limiting the performance of graphene, and achieve the effects of easy promotion, strong practicability, and high adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1 Experimental part

[0044] 1.1 Materials

[0045] Natural graphite flakes (8000 mesh, 99.95% purity), tetraethylsilicate (TEOS) and (3-aminopropyl)triethoxysilane (APTES) were purchased from Aladdin. Concentrated sulfuric acid (95-98%), concentrated hydrochloric acid (36-38%), hydrofluoric acid (40%) and potassium permanganate of analytical grade were purchased from Beijing Chemical Plant (China). Hydrogen peroxide (H 2 o 2 ) and sodium nitrate were provided by Laiyang Shikang Chemical Company. The above-mentioned concentrations are all mass concentrations.

[0046] 1.2 Amino-functionalized silica particles

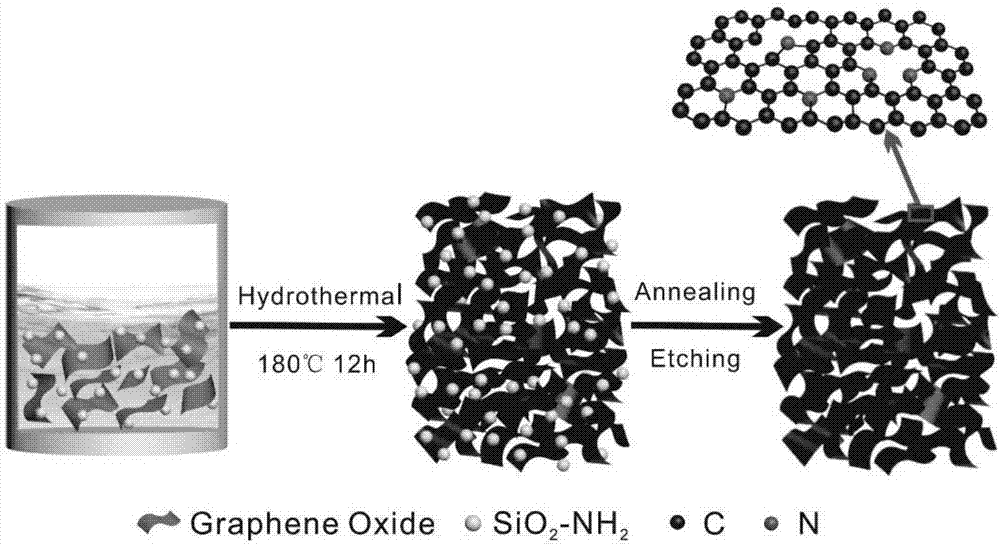

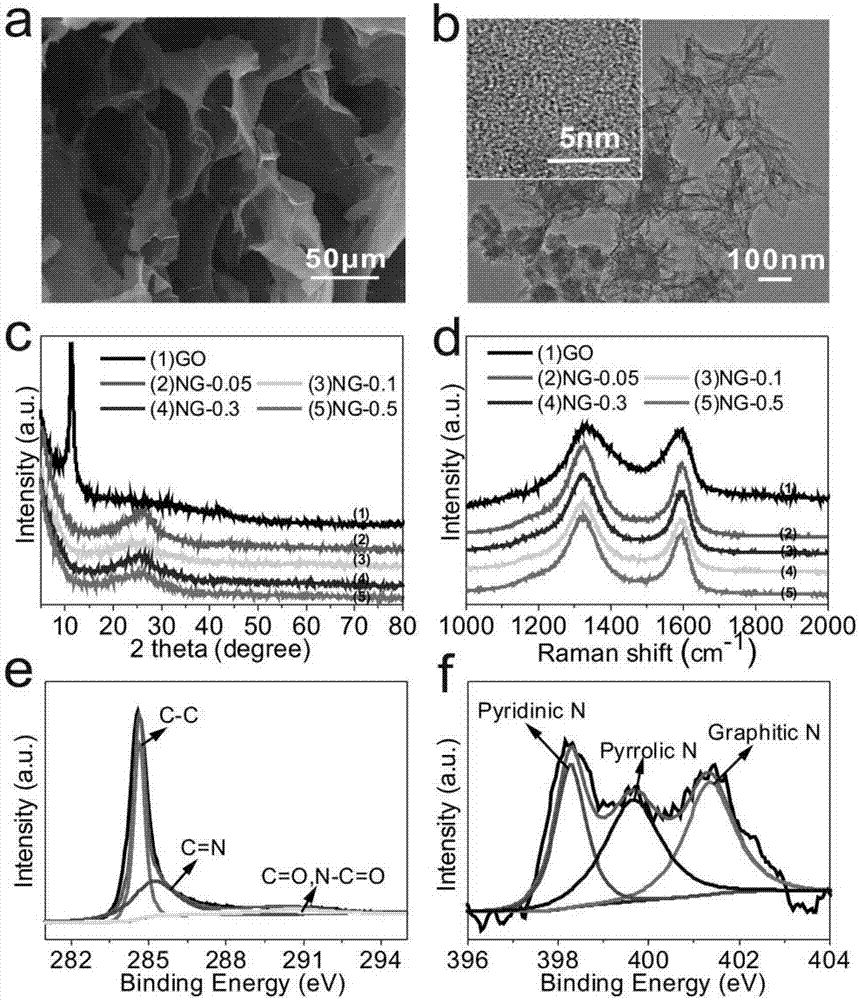

[0047] Silica was prepared by a modified Stober method. 1 g of silica particles was dispersed in ethanol (100 mL) and sonicated for 15 minutes to ensure uniform dispersion of the dispersion. Then 0.1430 g of APTES was dispersed in ethanol, and then slowly added into the silica suspension, and then stirred at 50° C. for about 24 hours under a nitrogen atmos...

Embodiment 2

[0087] SiO 2 -NH 2 The preparation method is with embodiment 1. Graphene oxide (GO) was prepared from natural graphite using a modified Hummers method. In the synthesis of N-doped airgel, 1 mL of SiO 2 -NH 2 The ethanol dispersions were respectively dispersed in 3 mg / mL GO aqueous solution. The suspension was then sealed in a Teflon-lined stainless steel autoclave for hydrothermal reaction at 160 °C for 14 h. The product was repeatedly washed with distilled water three times, and then freeze-dried to prepare an airgel. The prepared airgel was placed in a tube furnace with two temperature zones, and argon gas was passed through for 15 minutes to exhaust the air. and at 5°C min under argon -1 at a rate of 800 °C, followed by calcination at 800 °C for 1.5 h, and then cooled to room temperature. The resulting N-doped graphene gel was etched with hydrofluoric acid (3-5% molar concentration) and washed again with distilled water.

Embodiment 3

[0089] SiO 2 -NH 2 The preparation method is with embodiment 1. Graphene oxide (GO) was prepared from natural graphite using a modified Hummers method. In the synthesis of N-doped airgel, 1 mL of SiO 2 -NH 2The ethanol dispersions were respectively dispersed in 3 mg / mL GO aqueous solution. The suspension was then sealed in a Teflon-lined stainless steel autoclave for hydrothermal reaction at 172 °C for 13 h. The product was repeatedly washed with distilled water three times, and then freeze-dried to prepare an airgel. The prepared airgel was placed in a tube furnace with two temperature zones, and argon gas was passed through for 15 minutes to exhaust the air. and at 5°C min under argon -1 at a rate of 860 °C, followed by calcination at 860 °C for 1.4 h, and then cooled to room temperature. The resulting N-doped graphene gel was etched with hydrofluoric acid (3-5% molar concentration) and washed again with distilled water.

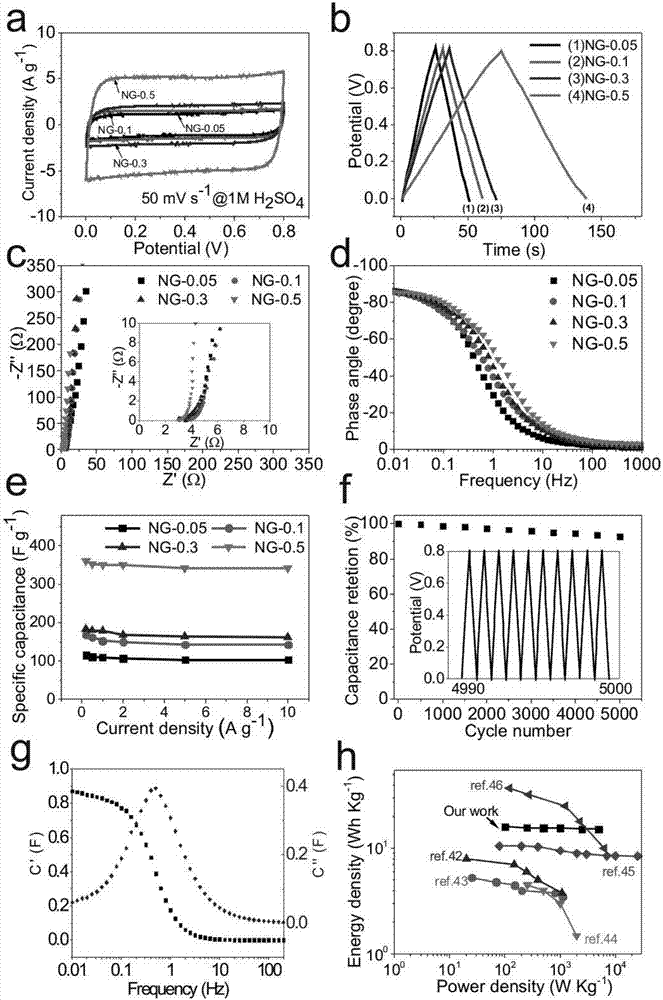

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power density | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com