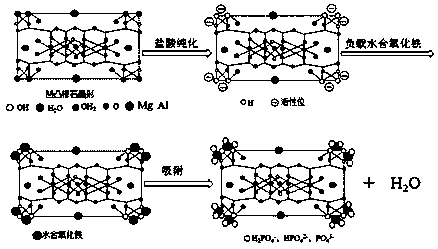

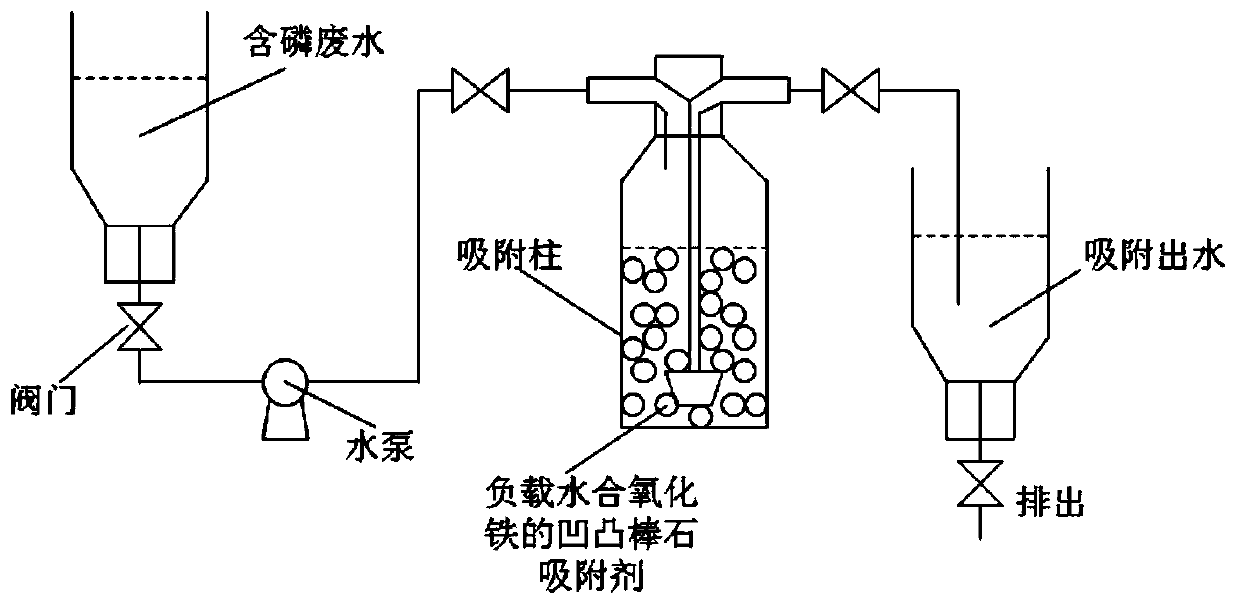

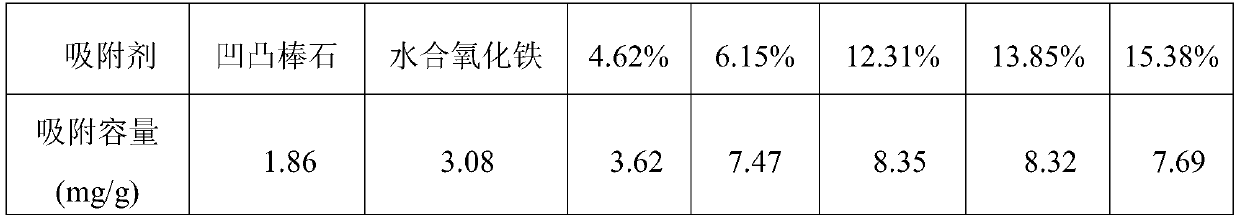

A method for deep adsorption and removal of phosphorus by using attapulgite loaded with hydrated iron oxide

A technology of hydrated iron oxide and attapulgite, applied in chemical instruments and methods, adsorption of water/sewage treatment, water pollutants, etc., can solve the problems of difficult to achieve adsorption effect, high consumption, low adsorption capacity, etc., to achieve Effects of low operating cost, reduced treatment cost, and high adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Grind and sieve coarse attapulgite powder to obtain attapulgite powder with a mesh number of 80, add the powder to 1mol / L hydrochloric acid solution at a solid-to-liquid ratio of 1:2, stir and mix for 1 hour, then wash with water until neutral and filter out For the precipitate, vacuum dry the precipitate at 80°C for 10 hours and grind it into powder to obtain the purified attapulgite powder; mix ferric nitrate with the purified attapulgite powder in a ratio of 1:5, and add water at a solid-to-liquid ratio of 1:15 After stirring well, use 5wt% dilute ammonia water to adjust the pH of the solution until no precipitation occurs, filter out the precipitate after aging, wash repeatedly until neutral, and dry at 80°C for 10 hours to obtain a modified powder; the ratio is 1:0.1 :0.02 Mix the modified powder with glass powder binder and starch pore-forming agent evenly in solid phase, add water and ethanol (alcohol-water ratio 1:1) and stir to form a mass, age for 6 hours, use ...

Embodiment 2

[0045] Grind and sieve coarse attapulgite to obtain attapulgite powder with a mesh number of 90, add the powder to a 1.5mol / L hydrochloric acid solution at a solid-to-liquid ratio of 1:3, stir and mix for 1.5 hours, then wash with water until neutral Filter out the precipitate, vacuum-dry the precipitate at 90°C for 11 hours, and then grind it into powder to obtain purified attapulgite powder; mix ferric nitrate with purified attapulgite powder in a ratio of 1:8, and use a solid-to-liquid ratio of 1: 18 After adding water and stirring well, use 6.5wt% dilute ammonia water to adjust the pH of the solution until no precipitation occurs. After aging, filter out the precipitate, wash it repeatedly until neutral, and dry it at 90°C for 11 hours to obtain a modified powder; 1:0.2:0.04 Mix the modified powder with glass powder binder and starch pore-forming agent evenly in solid phase, add water and ethanol (alcohol-water ratio 1:1.5) and stir to form a dough, age for 7 hours, and use...

Embodiment 3

[0050] Grind and sieve coarse attapulgite to obtain attapulgite powder with a mesh number of 100, add the powder to 2mol / L hydrochloric acid solution at a solid-to-liquid ratio of 1:4, stir and mix for 2 hours, then wash with water until neutral and filter out For the precipitate, vacuum dry the precipitate at 100°C for 12 hours and grind it into powder to obtain the purified attapulgite powder; mix ferric nitrate with the purified attapulgite powder at a ratio of 1:10, and add water at a solid-to-liquid ratio of 1:20 After stirring well, use 8wt% dilute ammonia water to adjust the pH of the solution until no precipitation occurs, filter out the precipitate after aging, wash repeatedly to neutrality, and dry at 100°C for 12 hours to obtain a modified powder; the ratio is 1:0.25 :0.05 Mix the modified powder with glass powder binder and starch pore-forming agent in solid phase evenly, add water and ethanol (alcohol-water ratio 1:2) and stir to form a mass, age for 8 hours, use a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com