Preparation process of seaweed ashitaba tea

A preparation process and technology of seaweed, applied in the field of preparation of seaweed ashitaba tea, can solve problems such as low production efficiency, reduced health care effect, difficult dissolution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] (1) Selective picking: Pick Ashitaba planted in the coastal area and irrigated with mountain spring water at 6-10 o'clock the next day after sprinkler irrigation, and the leaves of the 22-day growth period, retaining 0.5cm petioles, as tea-making raw materials;

[0078] (2) Freezing and bone opening: quickly freeze the fresh sun leaves at -10°C for 1 hour;

[0079] (3) Keeping green by immersion in ice: Pour the frozen leaves of Tomorrow’s leaves into mountain spring water for 5 minutes, and the water temperature is below 16°C;

[0080] (4) Dehydration and moisture determination: centrifugally dehydrate the ice-thawed Ashitaba at room temperature until the surface absorbs water ≤ 2%, until no dripping occurs;

[0081] (5) Enzyme spraying and chain opening: put Ashitaba with surface adsorption water ≤ 2% into a rotary machine with inner leaves, and the mass percentage of leaves and enzymes is 1:0:0.1. Spray food-grade enzymes (food grade, pectinase ≥ 85u / mL + cellulase ...

Embodiment 2

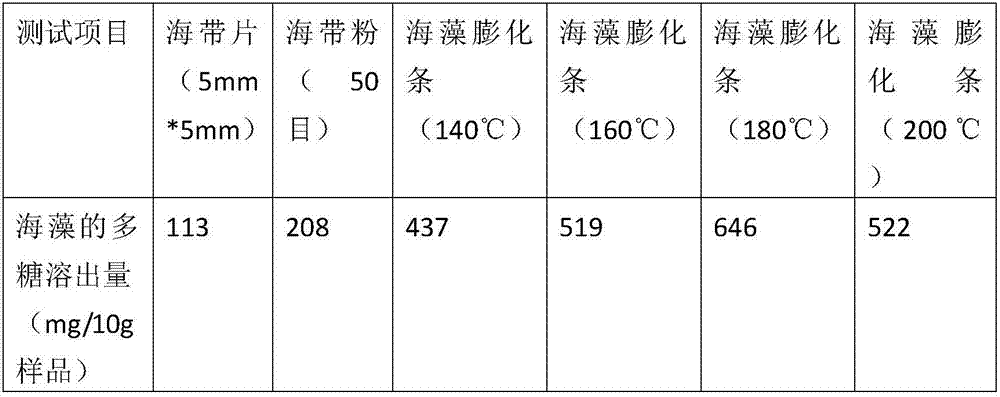

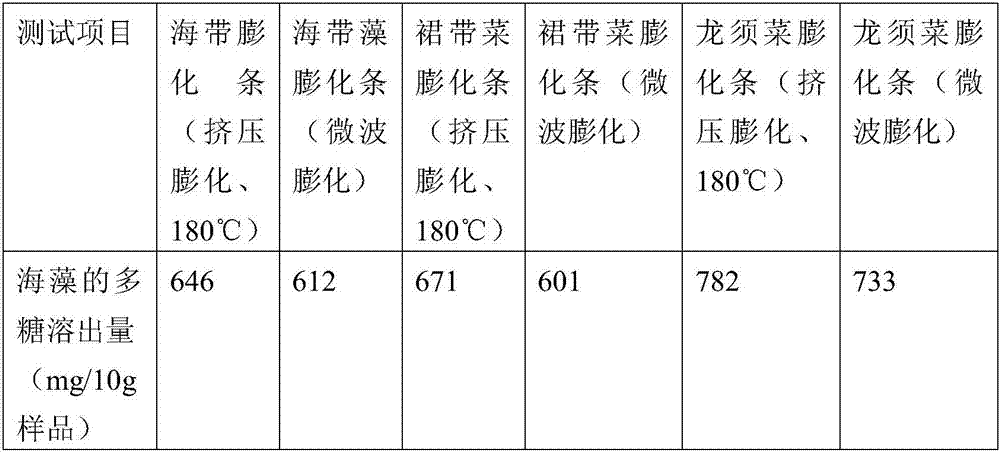

[0095] The difference from Example 1 is that the kelp is dried in an automatic dryer until the water content is 12%, puffed with an extruder at 130°C, cut into puffed strips of Φ2mm×10mm, and cooled to 50°C. The proportion of puffed kelp added is 51% by mass of tea; 12-16% dry shreds, then expanded at 130-210°C with an extruder, cut into puffed strips of Φ2mm×6-10mm, and cooled to 45-50°C ℃.

Embodiment 3

[0097] The difference from Example 1 is that the kelp is dried in an automatic dryer until the water content is 16%, puffed with an extruder at 210°C, cut into puffed strips of Φ3mm×6mm, and cooled to 50°C;

[0098] The proportion of the puffed kelp added is 45% by mass of the tea.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com