Pd/SnO2 nanospheres as well as preparation method and application thereof

A technology of nanospheres and nanoparticles, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., can solve the problems of complex preparation steps, and achieve simple preparation process and high production efficiency. High efficiency and good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Add 0.6 g SnCl 2 Dissolve it in 30 ml of deionized water containing 0.4 ml of 37% by mass, configure it as an aqueous solution of stannous chloride, and stir to obtain a transparent solution.

[0029] 2) Add 0.3ml of chloropalladium acid solution with a concentration of 10mg / ml to the above transparent solution dropwise, and stir at 80°C for 10h to obtain a brown suspension.

[0030] 3) The suspension was cooled, centrifuged, washed three times with distilled water and absolute ethanol respectively, and the obtained product was dried in a vacuum at 50°C to obtain Pd / SnO 2 nanospheres.

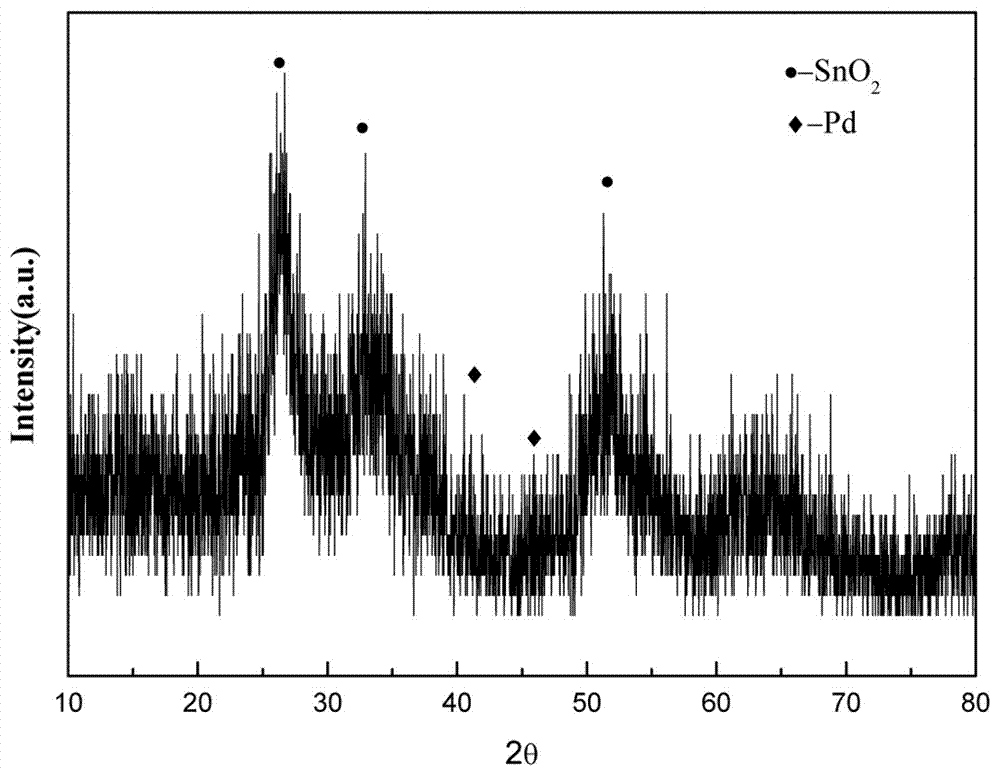

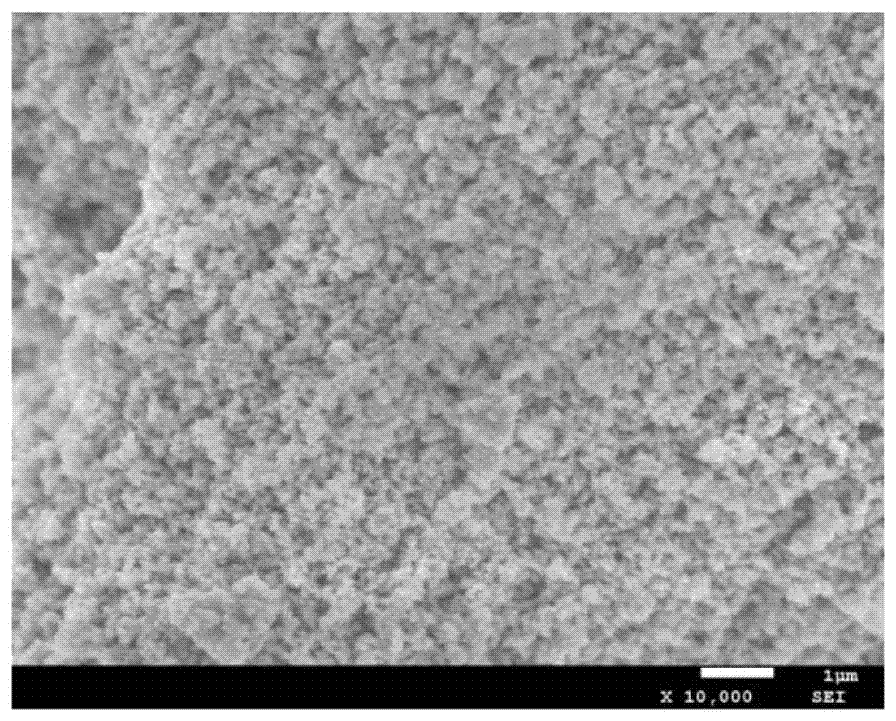

[0031] The Pd / SnO prepared above 2 The X-ray diffraction pattern of nanospheres is shown in Figure 1. The diffraction peaks are mainly tetragonal rutile phase tin oxide, and there is no obvious diffraction peak of Pd, mainly because the content of Pd is too low. The Pd / SnO prepared above 2 SEM image of the nanospheres (see Figure 2), from which it can be seen that the Pd / SnO 2 Th...

Embodiment 2

[0035] 1) Add 1 g SnCl 2 Dissolve it in 30 ml of deionized water containing 0.4 ml of 30% by mass, configure it as an aqueous solution of stannous chloride, and stir to obtain a transparent solution.

[0036] 2) Add 0.6ml of chloropalladium acid solution with a concentration of 10mg / ml to the above transparent solution dropwise, and stir at 80°C for 10h to obtain a brown suspension.

[0037] 3) The suspension was cooled, centrifuged, washed three times with distilled water and absolute ethanol respectively, and the obtained product was dried in a vacuum at 50°C to obtain Pd / SnO 2 nanospheres.

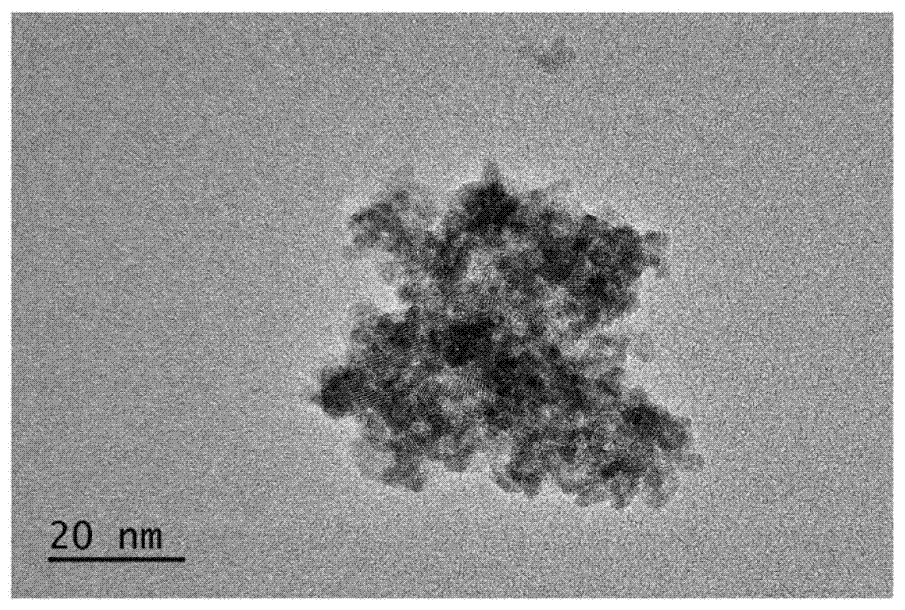

[0038] The Pd / SnO prepared above 2 The TEM image of the nanospheres is shown in Figure 4, from which it can be seen that the nanospheres are made of SnO 2 nanoparticles and Pd nanoparticles.

[0039] The above-prepared Pd / SnO 2Nanospheres are used to detect methanol, triethylamine and ethanol gases. The prepared gas sensor has an optimum working temperature of 240°C for 100ppm of ...

Embodiment 3

[0042] 1) Add 1 g SnCl 2 Dissolve it in 30 ml of deionized water containing 0.4 ml of 30% by mass, configure it as an aqueous solution of stannous chloride, and stir to obtain a transparent solution.

[0043] 2) Add 0.6ml of chloropalladium acid solution with a concentration of 10mg / ml to the above transparent solution dropwise, and stir at 80°C for 10h to obtain a brown suspension.

[0044] 3) The suspension was cooled, centrifuged, washed three times with distilled water and absolute ethanol respectively, and the obtained product was dried in a vacuum at 50°C to obtain Pd / SnO 2 nanospheres.

[0045] The above-prepared Pd / SnO 2 Nanospheres are used to detect methanol, triethylamine and ethanol gases. The prepared gas sensor has an optimum working temperature of 240°C for 500ppm of three different gases, which is better than that of pure SnO 2 Lower 20°C. The sensitivities to the three detection gases at the optimum working temperature are 102.1, 106.8 and 104.5 respectiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com