Function-enhanced BB fertilizer and production method thereof

A production method and functional technology, applied in the direction of nitrogen fertilizer, potassium fertilizer, magnesium fertilizer, etc., can solve the problems of not being able to meet the needs of special crops and trace elements, the content of medium and trace elements is not targeted, and the application effect is not outstanding, etc., to achieve Ease of large-scale production, product performance expansion, and flexible formula effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

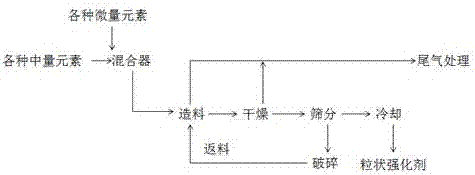

[0037] Such as figure 1 As shown, weigh 20.0 parts of bitter soil, 3.0 parts of boron oxide, 3.0 parts of zinc oxide, 3.0 parts of manganese oxide, 0.6 parts of molybdenum oxide, and 62 parts of phosphogypsum. Granulator, adding appropriate amount of process water for granulation, and then sent to the drum dryer for drying, and then into the drum cooler for cooling, and finally sieved to obtain the enhancer A.

[0038] The enhancer contains the following components by mass (in mass percent):

[0039] Mg 10.92%; S 10.15%; Ca 12.79%; B 0.98%; Zn 2.55%; Mn 2.45%; Mo 0.42%;

[0040] Average compressive strength of particles: 33N; water content 2.3%: particle size (2.00-4.00mm) 95%;

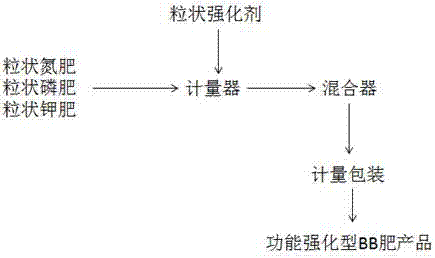

[0041] Such as figure 2 As shown, weigh 10 parts of granular nitrogen fertilizer (urea), 12 parts of granular potassium fertilizer (potassium sulfate), 9 parts of granular phosphate fertilizer (first-class diammonium phosphate), and 3 parts of granular enhancer A, and mix them in a twin-shaft mixe...

Embodiment 2

[0048] Such as figure 2 As shown, weigh 10 parts of granular nitrogen fertilizer (urea), 6 parts of granular potassium fertilizer (potassium sulfate), 7 parts of granular phosphate fertilizer (first-class diammonium phosphate), and 7 parts of granular enhancer A, and mix them in a twin-shaft mixer. Measuring and packaging to obtain a function-enhanced BB fertilizer product.

[0049] The function-enhanced BB fertilizer produced by this production process contains the following mass components (in mass percentage):

[0050] Total nutrients (N+P 2 o 5 +K 2 O) 38.2%, of which N 18.5%; P 2 o 5 9.7%;K 2 O 10.0%;

[0051] Water-soluble phosphorus accounts for the percentage of available phosphorus: 85%;

[0052] Mg 2.50%; S 5.93%; Ca 2.94%; B 0.22%; Zn 0.55%; Mn 0.56%; Mo 0.09%;

[0053] The product produced in this embodiment is carried out in a paddy field cultivation test, and compared with the common BB fertilizer that only applies the same amount and the same N, P, and ...

Embodiment 3

[0055] Such as figure 1 As shown, weigh 20.0 parts of bitter soil, 3.0 parts of boron oxide, 3.0 parts of zinc oxide, 3.0 parts of manganese oxide, and 62 parts of phosphogypsum. Add an appropriate amount of process water for granulation, then send it to a tumble dryer for drying, then enter a tumble cooler for cooling, and finally sieve to obtain the enhancer B.

[0056] The enhancer contains the following components by mass (in mass percent):

[0057] Mg 10.98%; S 10.15%; Ca 12.90%; B 0.99%; Zn 2.60%; Mn 2.45%; Average compressive strength of particles: 34N;

[0058] Such as figure 2 As shown, weigh 6 parts of granular nitrogen fertilizer (urea), 6 parts of granular potassium fertilizer (potassium sulfate), 7 parts of granular phosphate fertilizer (first-class diammonium phosphate), and 5 parts of granular enhancer B, and mix them in a twin-shaft mixer. Measuring and packaging to obtain a function-enhanced BB fertilizer product.

[0059] The function-enhanced BB fertili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com