Polycarboxylate-modified amino-alcohol cement grinding aid and preparation method thereof

A technology of cement grinding aids and alcohol amines, which is applied in the field of polycarboxylate modified alcohol amine cement grinding aids and its preparation, can solve the problem that the reaction progress of the product grinding aid performance is greatly affected, the performance stability is not ideal, Grinding aid effect is different, to achieve the effect of good cement dispersion, high polymerization activity and stable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

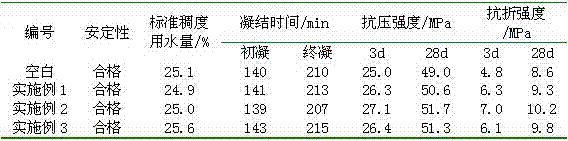

Examples

Embodiment 1

[0034] Weigh 360 g of methallyl polyoxyethylene ether and 320 g of water, and put them into a 1000 ml round bottom flask as the reaction bottom solution.

[0035] Preparation of dropping solution A: 19.44g of acrylic acid, 40g of water, stirred evenly and placed in a dropping bottle.

[0036] Prepare drop solution B: 0.57g ascorbic acid, 0.46g thioglycolic acid, 68g water, stir evenly and place in the drop bottle.

[0037] When the solid is completely dissolved, add 6.95g of sodium methacrylate and 2.64g of hydrogen peroxide. After 10 minutes, start adding liquid A and liquid B dropwise at the same time. Control the drop of material A for 1 hour and the drop of material B for 1.5 hours. Continue After reacting for 1 hour, heat up to 60-80°C, then add 13.41g of triethanolamine, keep it warm for 3 hours, cool down to 25°C, add 15.8g of 30% lye to adjust the pH to 6-7, and add water to adjust the mass concentration to 40%. The cement grinding aid product of the present invention...

Embodiment 2

[0039] Weigh 360 g of methallyl polyoxyethylene ether and 320 g of water, and put them into a 1000 ml round bottom flask as the reaction bottom solution.

[0040] Preparation of dropping solution A: 17.21g of acrylic acid, 43g of water, stirred evenly and placed in a dropping bottle.

[0041] Prepare drop solution B: 0.57g ascorbic acid, 0.37g thioglycolic acid, 68g water, stir evenly and place in the drop bottle.

[0042] When the solid is completely dissolved, add 6.95g of sodium methacrylate and 2.64g of hydrogen peroxide. After 10 minutes, start adding liquid A and liquid B dropwise at the same time. Control the drop of material A for 1 hour and the drop of material B for 1.5 hours. Continue After reacting for 1 hour, heat up to 60-80°C, then add 13.41g of triethanolamine, keep it warm for 3 hours, cool down to 25°C, add 14.0g of 30% lye to adjust the pH to 6-7, and add water to adjust the mass concentration to 40%. The cement grinding aid product of the present invention...

Embodiment 3

[0044] Weigh 360 g of methallyl polyoxyethylene ether and 320 g of water, and put them into a 1000 ml round bottom flask as the reaction bottom solution.

[0045] Preparation of dropping solution A: 15.89g of acrylic acid, 44g of water, stirred evenly and placed in a dropping bottle.

[0046] Prepare drop solution B: 0.57g ascorbic acid, 0.31g thioglycolic acid, 68g water, stir evenly and place in the drop bottle.

[0047] When the solid is completely dissolved, add 6.95g of sodium methacrylate and 2.64g of hydrogen peroxide. After 10 minutes, start adding liquid A and liquid B dropwise at the same time. Control the drop of material A for 1 hour and the drop of material B for 1.5 hours. Continue After reacting for 1 hour, heat up to 60-80°C, then add 13.41g of triethanolamine, keep the temperature for 3 hours, cool down to 25°C, add 12.9g of 30% lye to adjust the pH=6~7, add water to adjust the mass concentration to 40% The cement grinding aid product of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com