Yawing brake block and preparation method thereof

A brake pad and yaw technology, which is applied in the field of yaw brake pads and its preparation, can solve the problems of self-excited howling, high material hardness, and uneven braking, and achieve the effects of reducing wear, simple operation, and reducing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

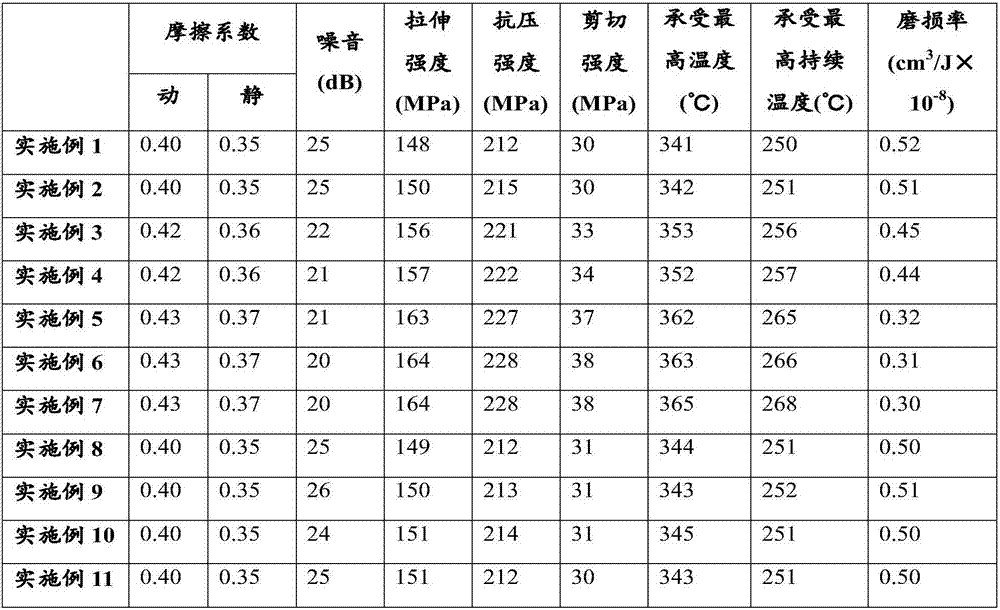

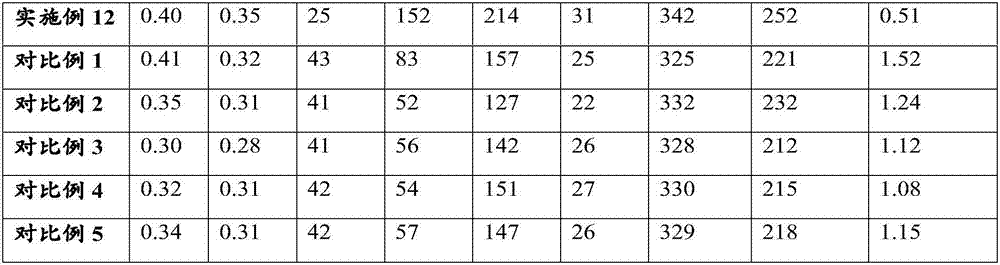

Examples

preparation example Construction

[0055] According to another aspect of the present invention, the present invention also provides a method for preparing the above-mentioned yaw brake pad, comprising the following steps:

[0056] (a) polyether ether ketone, carbon fiber, glass fiber, graphite, optional copper sulfide, optional carbon nanotubes, optional molybdenum sulfide, optional molybdenum sulfide, optional carbon nitride, and optional The zirconium carbide is mixed evenly;

[0057] (b) Injection molding the mixture to obtain a yaw brake pad.

[0058] The yaw brake pad provided by the invention is formed by injection molding, has simple operation and continuous process, significantly improves the preparation efficiency of the yaw brake pad, and reduces the preparation cost of the yaw brake pad.

[0059] In a preferred embodiment of the present invention, the preparation method of the yaw brake pad also includes a step (s), the step (s) is arranged between the step (a) and the step (b), and the step (s) is ...

Embodiment 1

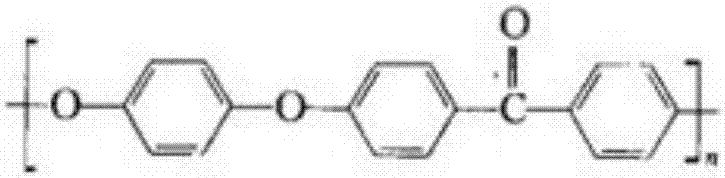

[0066] This embodiment provides a yaw brake pad, which is prepared from the following raw materials: 70 parts of polyether ether ketone, 20 parts of nano-scale carbon fiber, 5 parts of nano-scale glass fiber, and 5 parts of nano-scale graphite.

Embodiment 2

[0068] This embodiment provides a yaw brake pad, which is prepared from the following raw materials: 73 parts of polyether ether ketone, 18 parts of nano-scale carbon fiber, 4 parts of nano-scale glass fiber, and 4 parts of nano-scale graphite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com