Iodine-doped nano-Bi4O5Br2 visible-light-induced photocatalyst, preparation method and application thereof

A bi4o5br2, visible light technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as the limitation of separation efficiency of photogenerated electron-hole pairs, and achieve easy recycling and reuse, and easy availability of raw materials. , the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of iodine-doped nanometer visible light catalyst comprises the steps:

[0030] 1) Weigh 1mmol bismuth nitrate and dissolve it in 50mL ethylene glycol, stir to obtain solution A;

[0031] 2) Add 0.5 mmol of potassium bromide to solution A to obtain mixed solution B;

[0032] 3) Add 0.35 mmol potassium iodide to the mixed solution B obtained in step 2), stir and dissolve fully to obtain solution C;

[0033] 4) Put the mixed solution C obtained in step 3) into a microwave reactor and react with 400W power for 4 minutes;

[0034]5) After the microwave reaction mixture was cooled to room temperature, the precipitate was taken out and washed with deionized water and ethanol for 2 to 3 times, and then dried at 60°C for 12 hours to obtain iodine-doped Bi 4 o 5 Br 2 visible light catalyst.

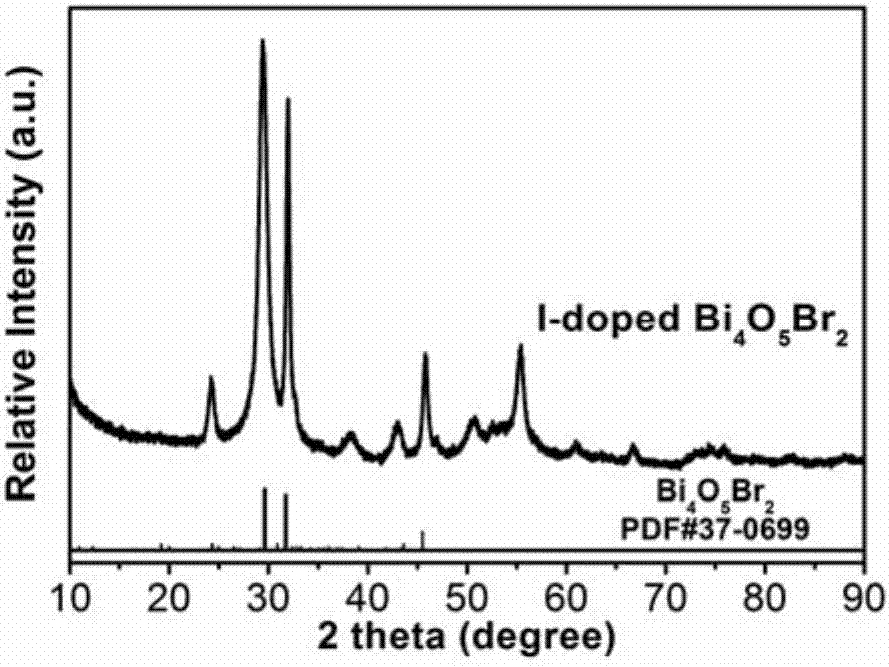

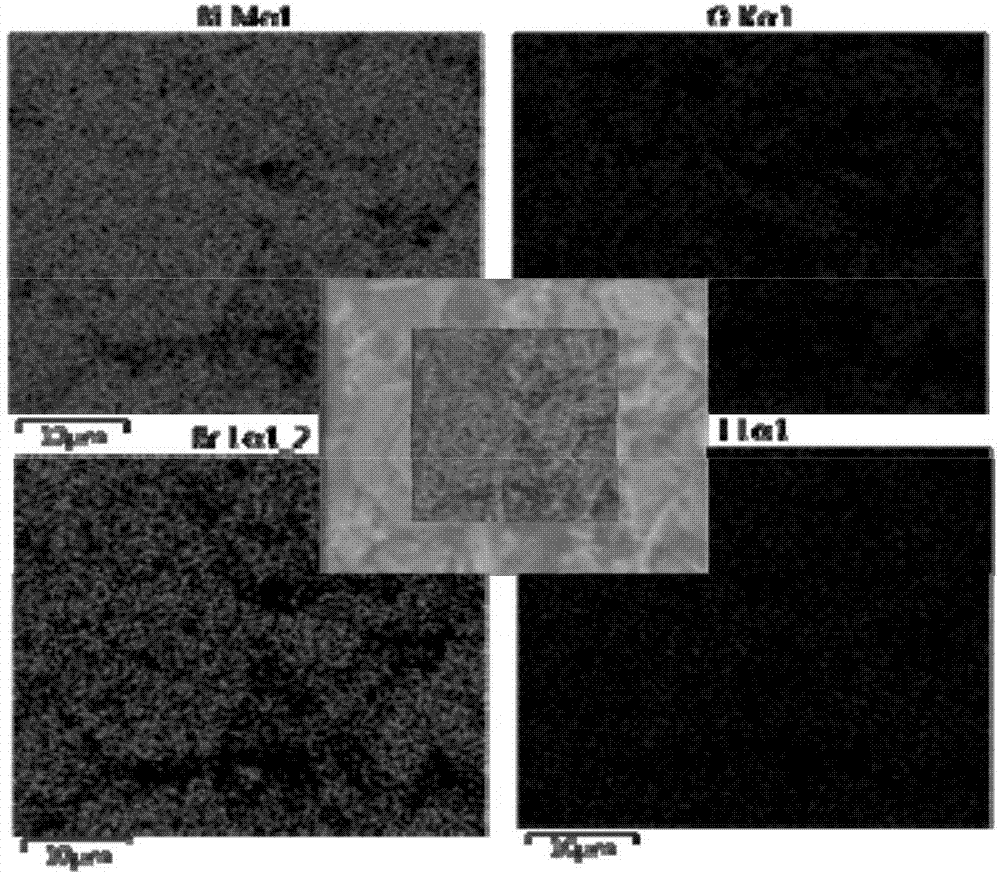

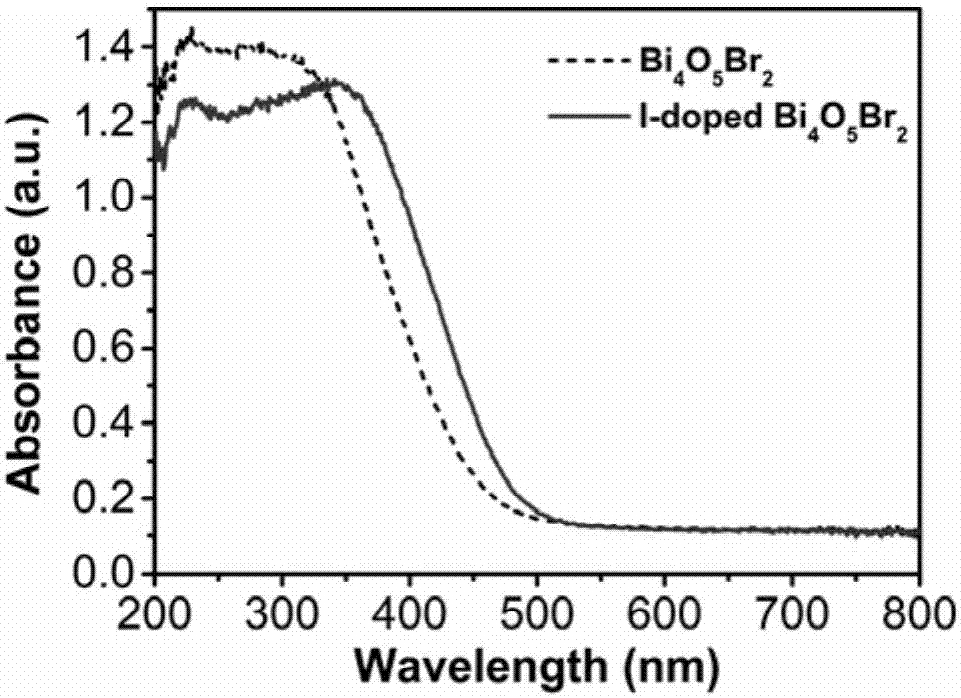

[0035] The resulting I-doped Bi 4 o 5 Br 2 Visible photocatalysts were characterized by XRD, SEM-EDS, and DRS, and the results are shown in Figures 1 to 3 sh...

Embodiment 2

[0039] The preparation method of iodine-doped nanometer visible light catalyst comprises the steps:

[0040] 1) Weigh 5mmol bismuth nitrate and dissolve it in 50mL ethylene glycol, stir to obtain solution A;

[0041] 2) Add 2.5 mmol of potassium bromide to solution A to obtain mixed solution B;

[0042] 3) Add 5 mmol potassium iodide to the mixed solution B obtained in step 2), stir and dissolve fully to obtain solution C;

[0043] 4) Put the mixed solution C obtained in step 3) into a microwave reactor and react with 400W power for 8 minutes;

[0044] 5) After the microwave reaction mixture was cooled to room temperature, the precipitate was taken out and washed with deionized water and ethanol for 2 to 3 times, and then dried at 100°C for 4 hours to obtain iodine-doped Bi 4 o 5 Br 2 visible light catalyst.

[0045] Use the iodine doped Bi of the present invention 4 o 5 Br 2 The degradation test of butylparaben and bisphenol A under visible light irradiation shows tha...

Embodiment 3

[0047] The preparation method of iodine-doped nanometer visible light catalyst comprises the steps:

[0048] 1) Weigh 1mmol bismuth nitrate and dissolve it in 50mL ethylene glycol, stir to obtain solution A;

[0049] 2) Add 0.5 mmol of potassium bromide to solution A to obtain mixed solution B;

[0050] 3) Add 0.1 mmol potassium iodide to the mixed solution B obtained in step 2), stir and dissolve fully to obtain solution C;

[0051] 4) Put the mixed solution C obtained in step 3) into a microwave reactor and react with 200W power for 10 minutes;

[0052] 5) After the microwave reaction mixture was cooled to room temperature, the precipitate was taken out and washed with deionized water and ethanol for 2 to 3 times, and then dried at 60°C for 12 hours to obtain iodine-doped Bi 4 o 5 Br 2 visible light catalyst.

[0053] Use the iodine doped Bi of the present invention 4 o 5 Br 2 The degradation test of butylparaben and bisphenol A under visible light irradiation shows ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com