Method for preparing boron-doped YBCO (Yttrium Barium Copper Oxide) superconducting film by one-step heat treatment process

A boron-doped, superconducting film technology, applied in the field of materials, can solve the problems of limiting film thickness, time-consuming and power consumption, and harmful to human body, so as to reduce cracking and insufficient thickness, improve film-making efficiency, and ensure film-forming quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In this embodiment, the spin coating equipment is the SC-1B glue homogenizer produced by Beijing Chuangweina Technology Co., Ltd. The parameters of the glue homogenizer are set: 300r / min speed homogenizes the glue for 10s, and then the speed rises to 5000r / min within 2s , keep the speed for 30s, and then stop naturally.

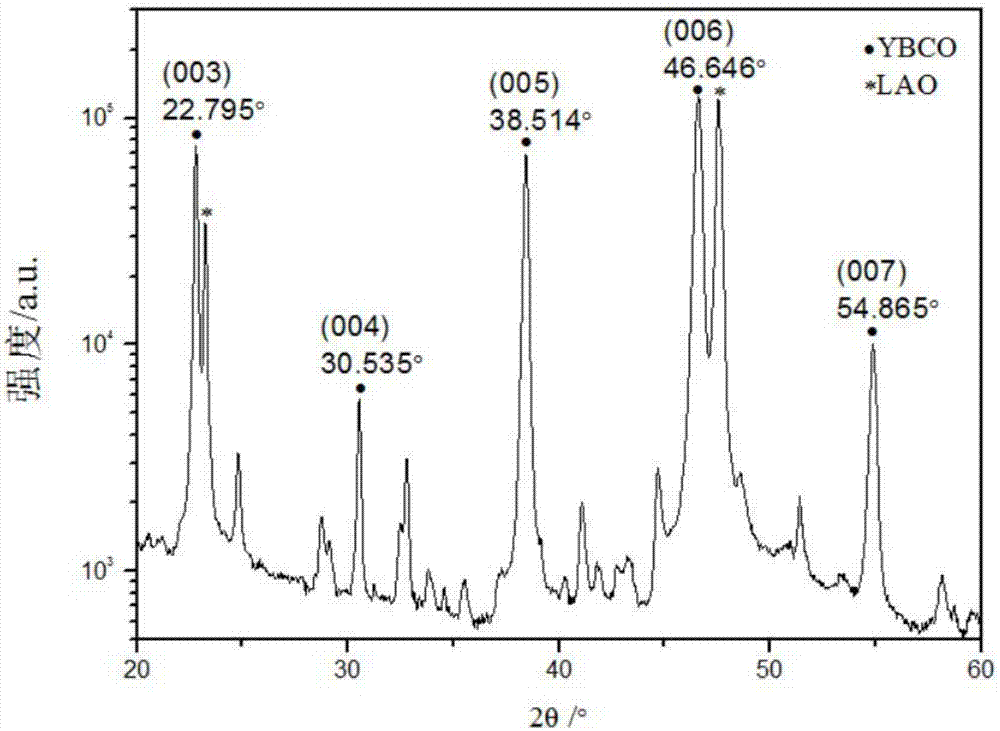

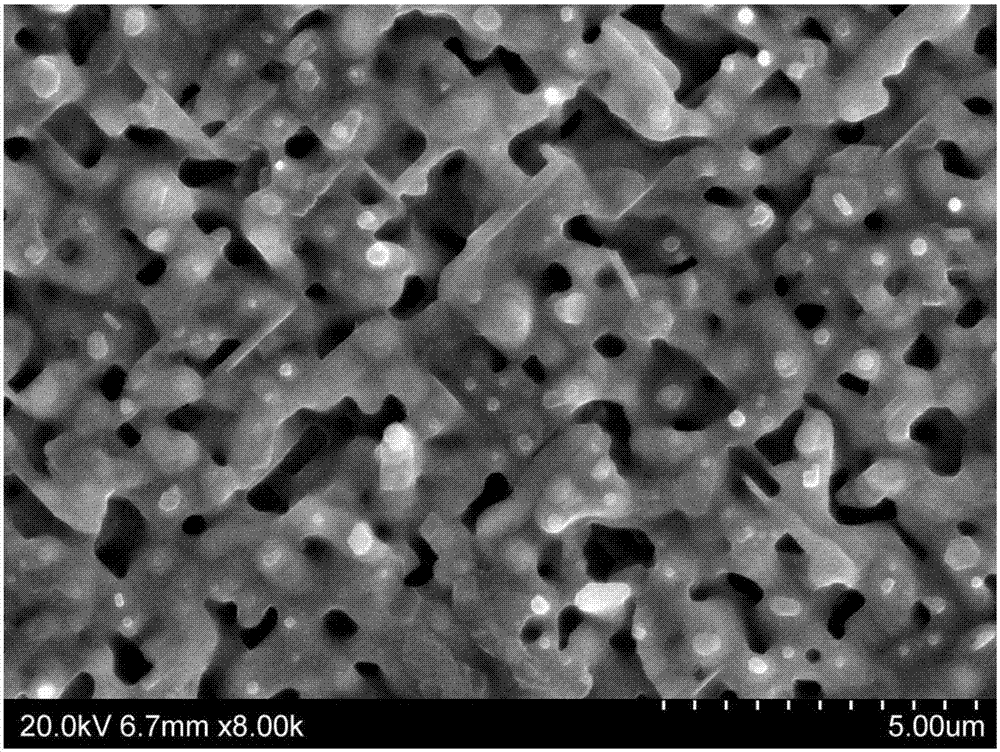

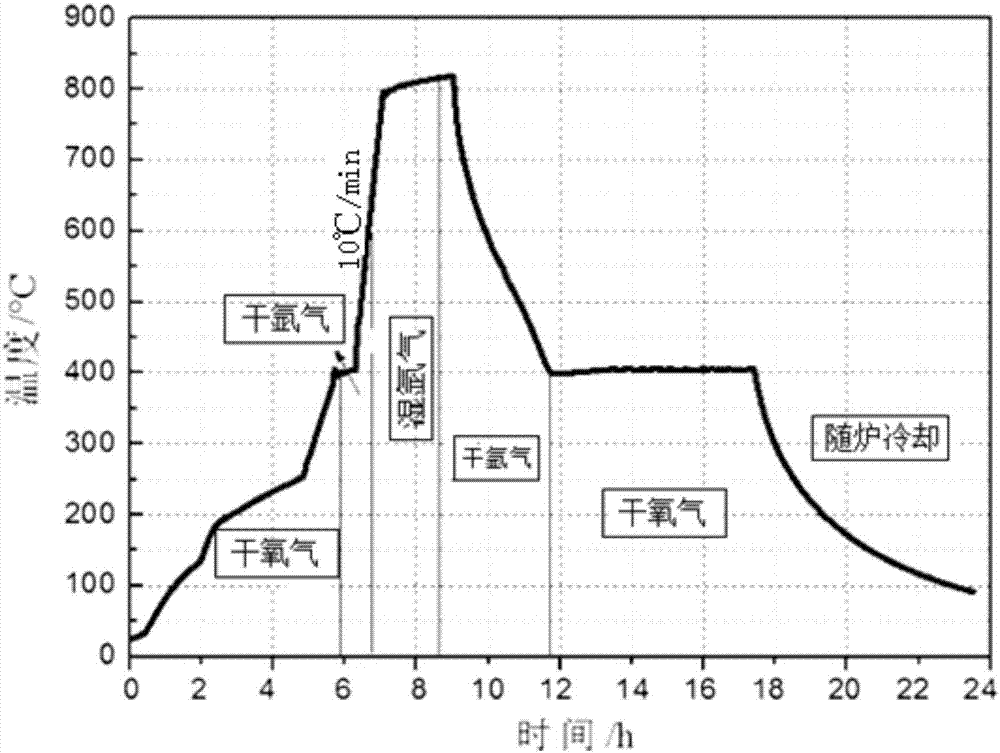

[0042] Yttrium acetate, barium trifluoroacetate, copper isooctanoate, and dehydrated alcohol used in this embodiment are all analytical reagents; when configuring the yttrium-barium solution, in order to make the solid dissolve quickly and prevent the solute from overheating and decomposing, the temperature of the solution is controlled. 70~80℃, the total concentration of cations in the prepared yttrium barium copper solution is 1.5~2.0mol / L; the single crystal lanthanum aluminate (LaAlO 3 , LAO) substrate is a commercially available product with a size of 1cm×1cm×0.5mm; the treatment is performed in a ventilated tube furnace.

[0043] Dissolve yttriu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com