A kind of method for preparing tea polyphenol adsorption material by modifying cellulose

An adsorption material, tea polyphenol technology, applied in the direction of selective adsorption, chemical instruments and methods, other chemical processes, etc., can solve the problem of inability to separate tea polyphenols, and achieve the effect of fast adsorption rate, not easy to fall off, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

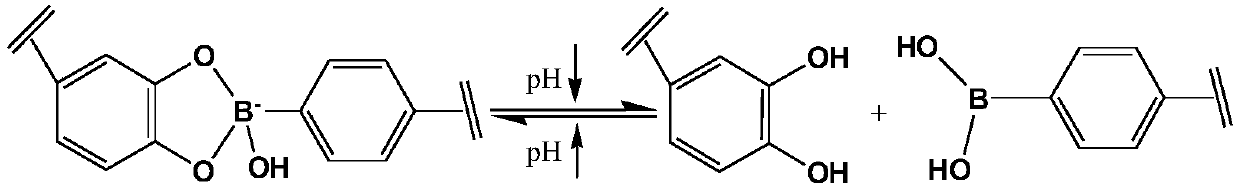

[0039] In the preparation process of the phenylboronic acid modified cellulose, the reaction time is 2-24 hours, the reaction temperature is 40°C-85°C, and the stirring rate is 200-400r / min.

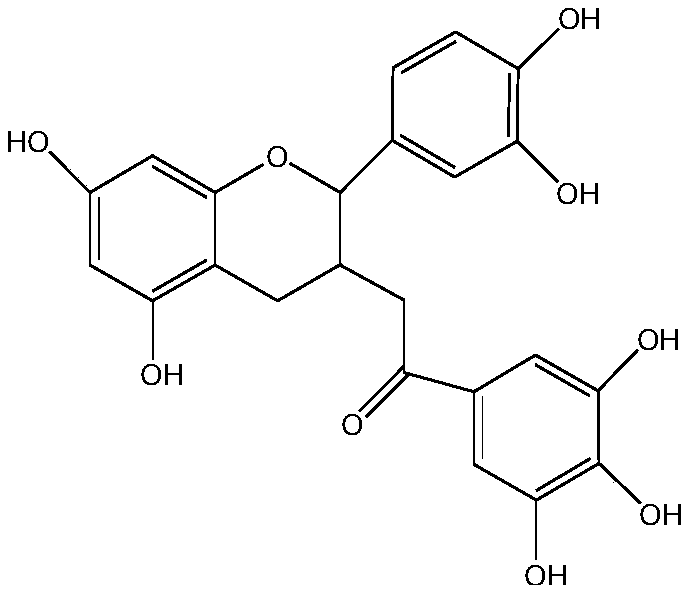

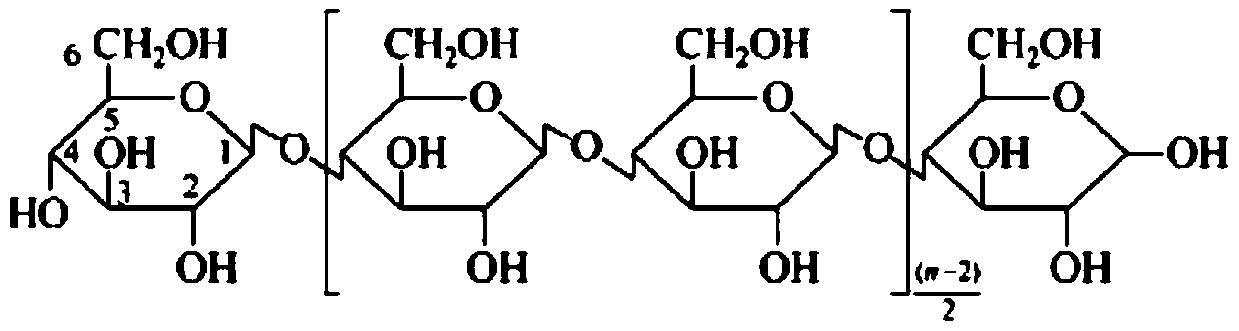

[0040] The reaction mechanism of phenylboronic acid and tea polyphenols is:

[0041]

[0042] The test method for the adsorption performance of modified cellulose to tea polyphenols is to use the cellulose before and after modification as the adsorbent, and the tea polyphenols as the adsorbate, place it in a conical flask, and adjust the gap between the cellulose and the adsorbate. ratio, and adjust the pH of the adsorbate to 9-10, place it in an oscillator to oscillate for adsorption, control a certain oscillation frequency and oscillation time (that is, the adsorption time), take the solution after adsorption, and dilute the concentration to the detection range of the instrument Inside, the concentration of each substance in the adsorbate before and after adsorption was detected by ...

Embodiment 1

[0046] Add 10g of eucalyptus cellulose into 1000mL of distilled water, stir and disperse for 12h under the action of mechanical stirring at 200r / min, then dissolve 0.1g of initiator cerium ammonium nitrate and 2g of 4-vinylphenylboronic acid in 10mL of distilled water, and slowly add to the reaction The device was protected by nitrogen, and the reaction temperature was controlled at 40°C. After 24 hours of reaction, phenylboronic acid modified cellulose was obtained. After the cellulose was extracted with distilled water and ethanol for 24 hours, it was dried in vacuum at 45°C for 24 hours, and the final product was obtained. Tea polyphenols adsorption material prepared by cellulose modification.

Embodiment 2

[0048] Add 80g of bamboo cellulose to 1000mL of distilled water, stir and disperse for 12h under the action of mechanical stirring at 400r / min, then dissolve 1.5g of initiator ammonium persulfate and 20g of 4-vinylphenylboronic acid in 10mL of distilled water, and slowly add to the reaction device , nitrogen protection, control the reaction temperature at 85°C, after 2 hours of reaction, phenylboronic acid modified cellulose was obtained, the cellulose was extracted with distilled water and ethanol for 24 hours, and then vacuum dried at 45°C for 24 hours to obtain the final product, fiber Tea polyphenols adsorption material prepared by element modification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com