Method for extracting, separating and purifying four main anthocyanins from blackcurrant residue

An anthocyanin and pomace technology, applied in chemical instruments and methods, organic chemistry, preparation of sugar derivatives, etc., can solve the problems of lack of anthocyanin products, difficult to apply, cumbersome methods, etc., to shorten the experimental period and time-consuming. The effect of shortening and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

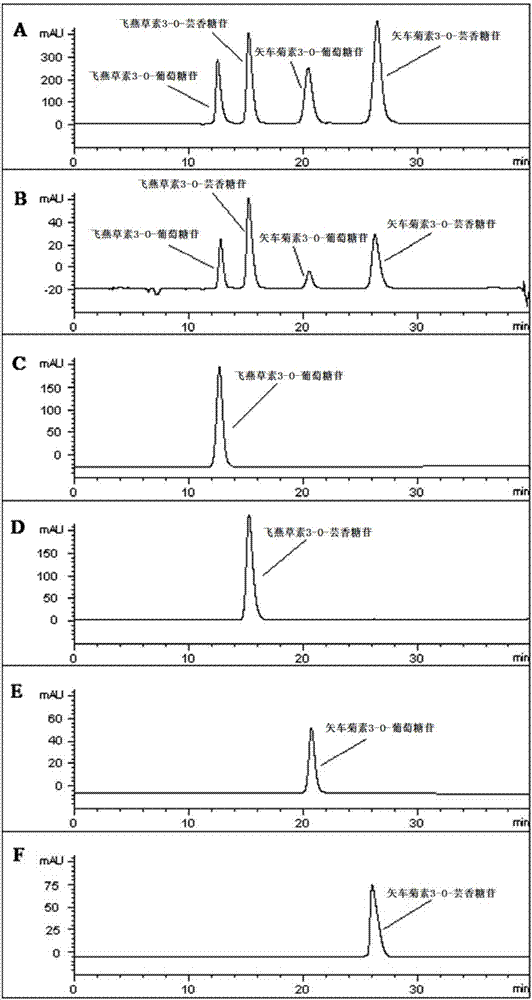

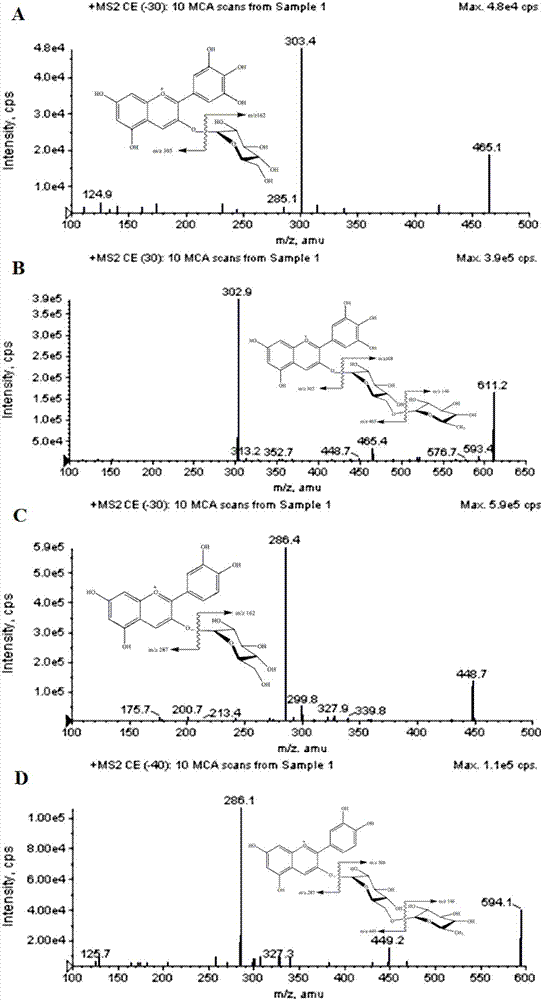

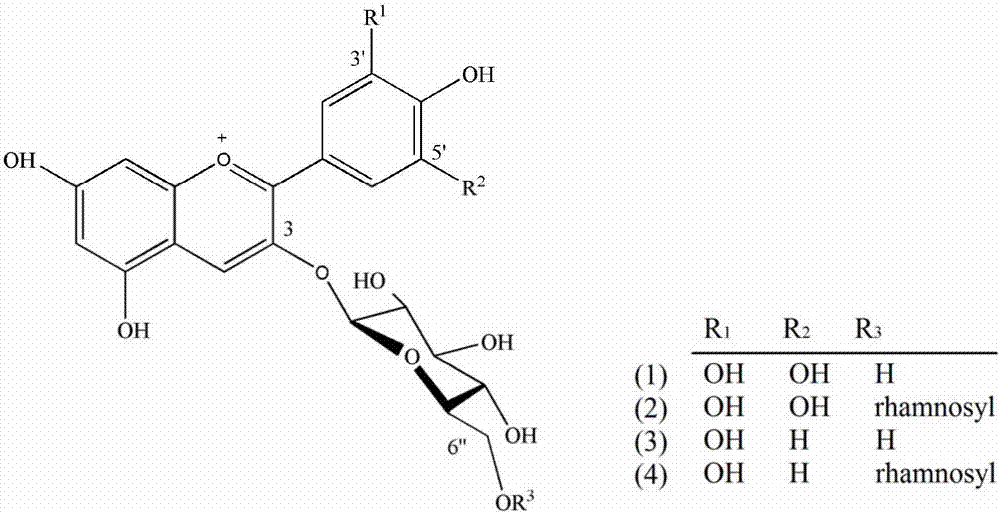

Embodiment 1

[0036] Add 1kg of blackcurrant pomace to 6L of water for homogenization and crushing three times, 5 minutes each time, adjust the pH of the slurry to 4 with citric acid, add 30g of cellulase, and then put the slurry in a constant temperature shaker for enzymatic hydrolysis at a temperature of 30°C 2h, filter with suction, and collect the filtrate and residue. In filter residue, add 12L ethanol and carry out negative pressure cavitation extraction, ethanol concentration is 80%, and negative pressure cavitation extraction pressure is-0.05MPa, extracts 3 times under room temperature, extraction time is 30min, the filtrate that obtains and step (1) The filtrates were combined, concentrated under reduced pressure and recovered to remove the solvent to obtain 168.6 g of blackcurrant extract. Select macroporous adsorption resin type AB-8 resin. After the above-mentioned blackcurrant extract was dispersed in 3L of pure water, the supernatant was centrifuged and loaded into a macropor...

Embodiment 2

[0038]Add 1kg of blackcurrant pomace to 8L of water to homogenize and break three times, each time for 5min, adjust the pH of the slurry to 5 with hydrochloric acid, add 50g of cellulase pectinase mixed enzyme, then put the slurry into a constant temperature shaker, Enzymolysis at 45°C for 4 hours, suction filtration, and collection of filtrate and residue. Add 15L ethanol to the filter residue and carry out negative pressure cavitation extraction, ethanol concentration is 80%, negative pressure cavitation extraction pressure is-0.07MPa, extract 4 times under room temperature, extraction time is 40min, the filtrate obtained and step (1) The filtrates were combined, concentrated under reduced pressure and recovered to remove the solvent to obtain 189.3 g of blackcurrant extract. Use macroporous adsorption resin model D101 resin. After the above-mentioned blackcurrant extract was dispersed in 2L of pure water, the supernatant was centrifuged and loaded into a macroporous adsorp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com