Preparation method and application of GQDs (graphene quantum dots)

A technology of graphene quantum dots and uses, applied in the directions of graphene, separation methods, chemical instruments and methods, etc., can solve the problems of low target recognition response, cumbersome sample pretreatment, large size differences, etc., to improve the recognition ability, Uniform size and high quantum yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

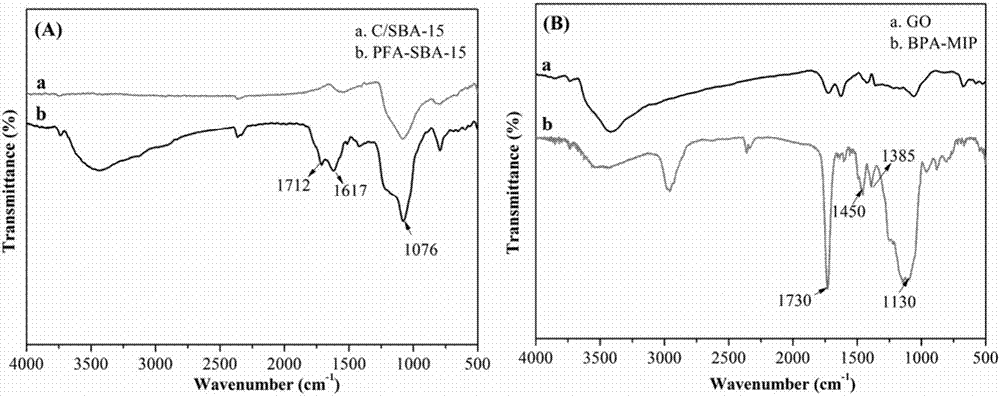

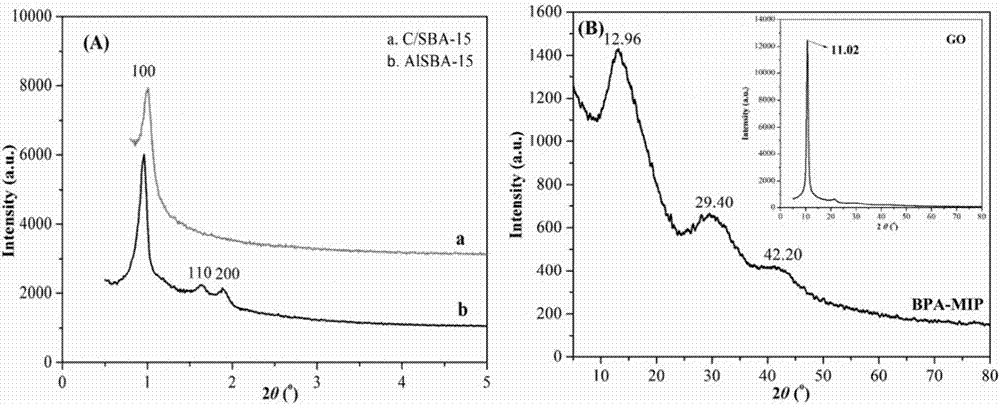

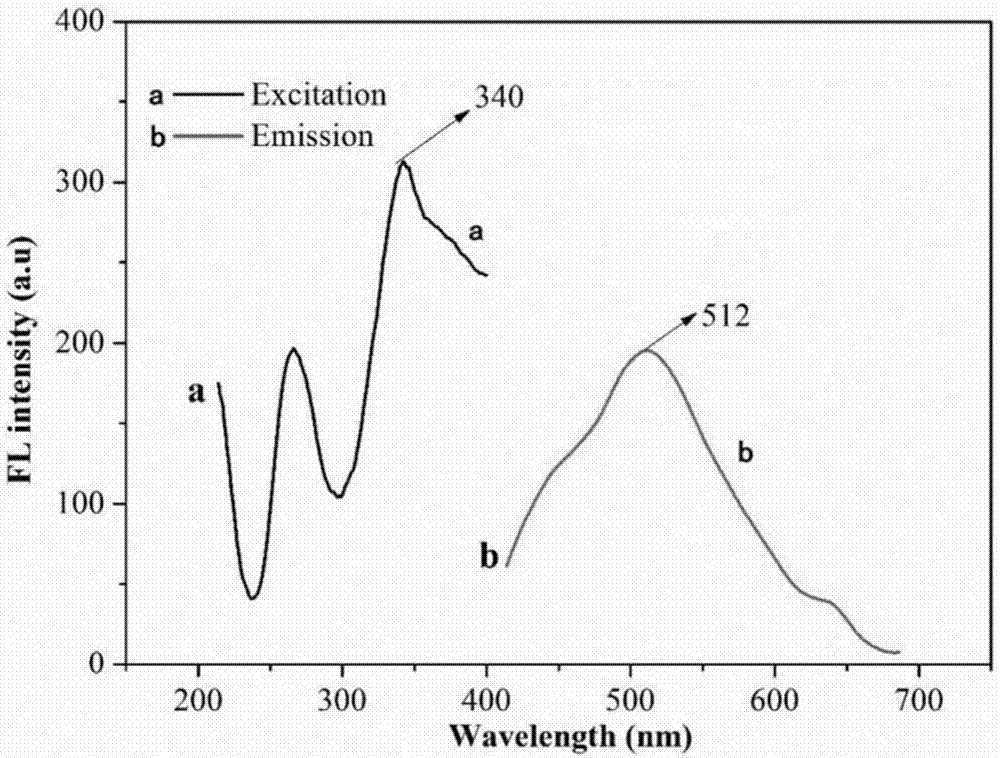

[0029] (1) Preparation of graphene quantum dots (GQDs) based on SBA-15 microreactor

[0030] 1g SBA-15 dispersed to contain 0.5g AlCl 3 In the ethanol solution, stir vigorously for 12h. Then the mixture was put into a rotary evaporator for rotary evaporation, and evaporated to dryness at 50°C. Finally, the solid was transferred to a tube furnace at 550°C for 5 hours in the air to obtain AlSBA-15. Take 1.0g of prepared AlSBA-15, evenly drop 2.5mL FA on its surface for impregnation, and then remove excess FA in an oven at 80°C. Grind the prepared solid (PFA-SBA-15) into powder, transfer to a tube furnace, burn at 150°C for 1 hour, then raise the temperature to 300°C at 10°C / min, then raise the temperature to 850°C at 5°C / min and keep for 4 hours. 10mL / min N 2 Polycondensation is carried out in the gas flow, and a thin carbon layer is formed on the inner wall of AlSBA-15 channel to obtain C / SBA-15. Weigh 1g of C / SBA-15 into a polytetrafluoroethylene reactor, add 6mL of conce...

Embodiment 2

[0034] (1) Preparation of graphene quantum dots (GQDs) based on SBA-15 microreactor

[0035] 1g SBA-15 dispersed to contain 1g AlCl 3 In the ethanol solution, stir vigorously for 12h. Then the mixture was put into a rotary evaporator for rotary evaporation, and evaporated to dryness at 50°C. Finally, the solid was transferred to a tube furnace at 550°C for 5 hours in the air to obtain AlSBA-15. Take 1.0g of prepared AlSBA-15, evenly drop 3.0mL FA on its surface for impregnation, and then remove excess FA in an oven at 80°C. Grind the prepared solid (PFA-SBA-15) into powder, transfer to a tube furnace, burn at 150°C for 2h, then raise the temperature to 300°C at 10°C / min, then raise the temperature to 850°C at 5°C / min and keep for 4.5h , 10mL / min N 2 Polycondensation is carried out in the gas flow, and a thin carbon layer is formed on the inner wall of AlSBA-15 channel to obtain C / SBA-15. Weigh 1g of C / SBA-15 into a polytetrafluoroethylene reactor, add 8mL of concentrated ...

Embodiment 3

[0039] (1) Preparation of graphene quantum dots (GQDs) based on SBA-15 microreactor

[0040] 1g SBA-15 dispersed to contain 1.5g AlCl 3 In the ethanol solution, stir vigorously for 12h. Then the mixture was put into a rotary evaporator for rotary evaporation, and evaporated to dryness at 50°C. Finally, the solid was transferred to a tube furnace at 550°C for 5 hours in the air to obtain AlSBA-15. Take 1.0g of prepared AlSBA-15, evenly drop 4.0mL FA on its surface for impregnation, and then remove excess FA in an oven at 80°C. Grind the prepared solid (PFA-SBA-15) into powder, transfer to a tube furnace, burn at 150°C for 2.5h, then raise the temperature to 300°C at 10°C / min, then raise the temperature to 850°C at 5°C / min and keep for 5h , 10mL / min N 2 Polycondensation is carried out in the gas flow, and a thin carbon layer is formed on the inner wall of AlSBA-15 channel to obtain C / SBA-15. Weigh 1g of C / SBA-15 into a polytetrafluoroethylene reactor, add 10mL of concentrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ll | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com