Modified silicon rubber sheath material and preparation method thereof

A technology of rubber sheath and modified silicon, which is applied in the direction of rubber insulators and organic insulators, can solve the problems of silicone rubber oil resistance, poor corrosion resistance, low mechanical strength, and low mechanical strength of materials, so as to achieve good oil resistance and increase The effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

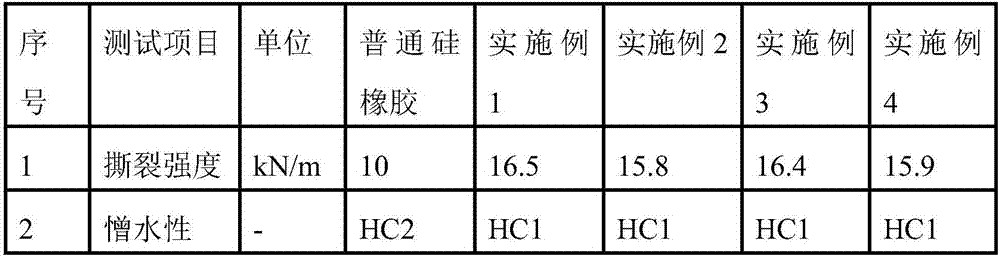

Examples

preparation example Construction

[0032] A preparation method of modified silicone rubber sheath material, comprising the steps of:

[0033] (1) To prepare vinylphenyl silsesquioxane, weigh 18.7mL of phenyltrimethoxysilane and 16.5mL of dimethylvinylethoxysilane to form an oil phase, weigh 12mL of isopropanol, 20mL of deionized water and 3mL of concentrated hydrochloric acid form the water phase, add it to a four-necked flask equipped with a stirrer, a thermometer, and a reflux condenser, pass in nitrogen protection, heat the oil bath to 75°C while stirring, react for 10 hours, and let the upper layer stand still Pour out the acidic water, add 100mL of deionized water, wash with water at 60°C until neutral, then vacuum dry at 100°C and -0.1MPa for 10h to obtain vinylphenyl silsesquioxane;

[0034] (2) To prepare modified nanofibers, first prepare 200mL of alcohol aqueous solution with a volume ratio of 1:1, adjust the pH value to 5.0 with 0.1M hydrochloric acid solution, and obtain a mixed solution; disperse 1...

Embodiment 1

[0039] A preparation method of modified silicone rubber sheath material, comprising the steps of:

[0040] (1) To prepare the crosslinking agent vinylphenyl silsesquioxane, weigh 18.7mL of phenyltrimethoxysilane and 16.5mL of dimethylvinylethoxysilane to form the oil phase, and weigh 12mL of isosilsesquioxane Propanol, 20mL deionized water and 3mL concentrated hydrochloric acid form the water phase, add it into a four-necked flask equipped with a stirrer, a thermometer, and a reflux condenser, pass in nitrogen protection, heat the oil bath to 75°C under stirring, react for 10h, and statically Pour out the upper layer of acidic water, add 100mL of deionized water, wash with water at 60°C until neutral, then vacuum dry at 100°C and -0.1MPa for 10h to obtain vinylphenyl silsesquioxane;

[0041] (2) To prepare modified nanofibers, first prepare 200mL of alcohol aqueous solution with a volume ratio of 1:1, adjust the pH value to 5.0 with 0.1M hydrochloric acid solution, and obtain ...

Embodiment 2

[0045] Crosslinking agent vinyl phenyl silsesquioxane, modified nanofiber, flame retardant poly[benzotin-cyclotrimeric phosphazene-1,3,5-triazine-2,4,6-triamine ] The preparation method is the same as Example 1, the difference of the preparation method of the modified silicone rubber sheath material is that step (4): take by weight 50 parts by weight silicone rubber, 10 parts by weight fluororubber, 5 parts by weight Fluorosilicone rubber was added to the internal mixer, the temperature was raised to 90°C, and banburying was carried out at a speed of 150r / min for 5 minutes, and then 3 parts by weight of heptadecafluorodecyltrimethoxysilane and 3 parts by weight of polyvinylidene fluoride were added in the same Mix at temperature and rotating speed for 10 minutes to obtain the main material, then raise the banburying temperature to 105°C, add 4 parts by weight of isocyanate triethoxysilane modified titanium boride nanofibers, 3 parts by weight of polyacrylonitrile organic fibers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com