Device and method for preparing two-dimensional transmission metal dichalcogenide (TMDC) atom crystal material under normal pressure

A technology of crystal materials and atoms, which is applied in the field of devices for preparing two-dimensional TMDC atomic crystal materials, can solve the problems of source material loss, discontinuity, poor repeatability, etc., and achieve the effect of saving resources and costs and improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

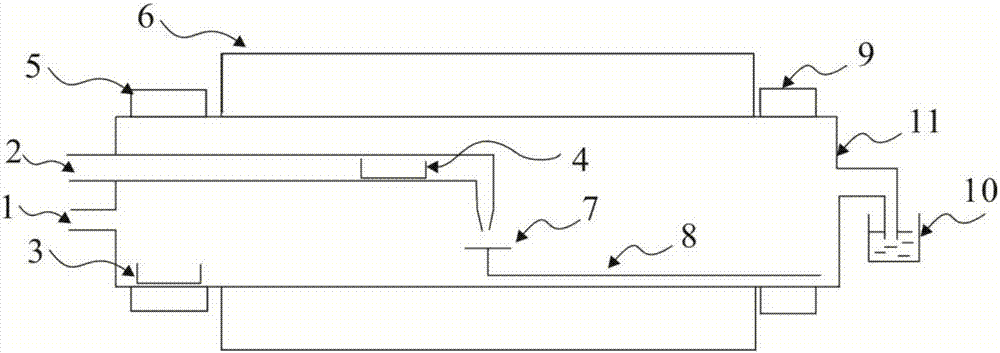

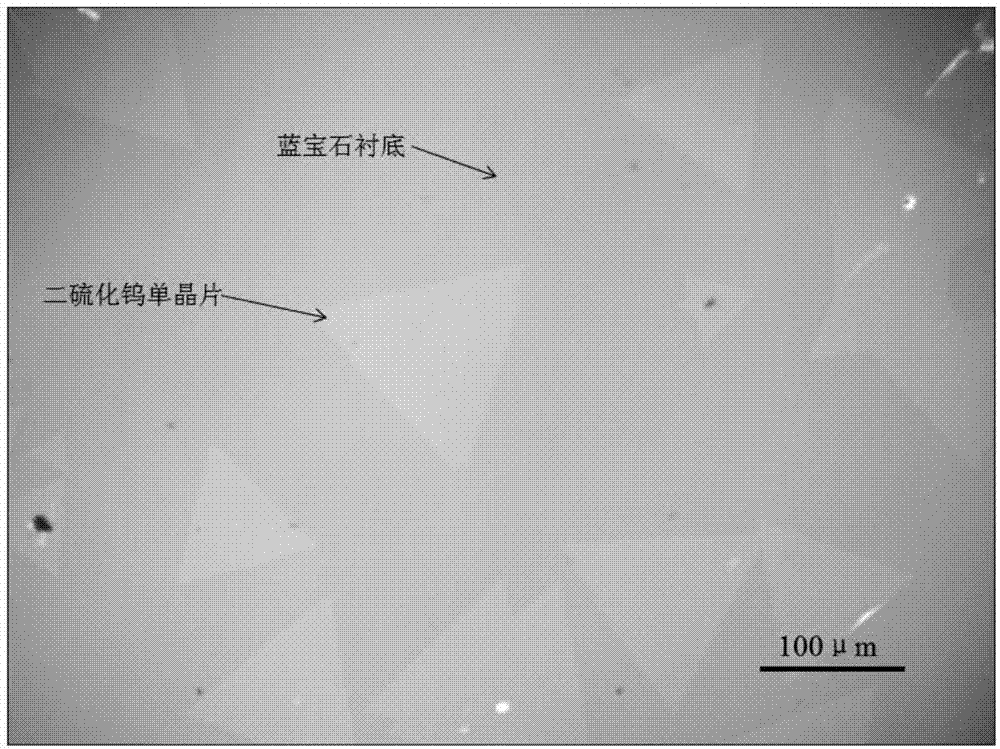

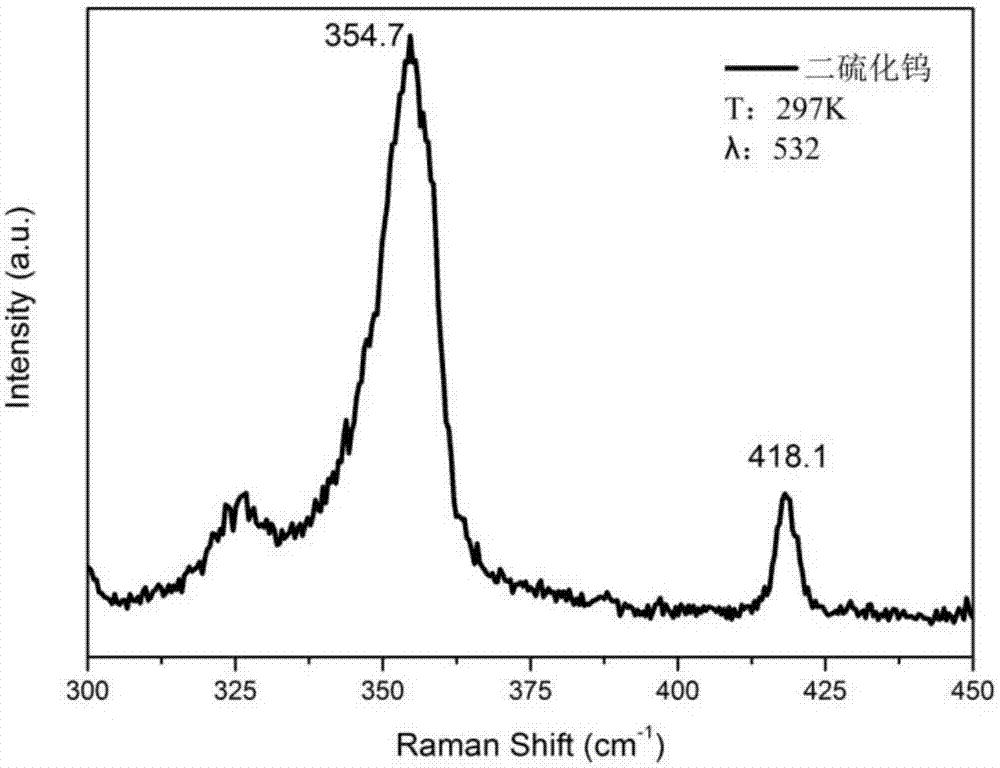

[0039] The method for preparing a tungsten disulfide single wafer in the order of 100 microns comprises the following steps: placing tungsten trioxide (500mg) in the carrier boat 2 4 in the quartz high-temperature tube furnace 11, so that the tungsten trioxide is located in the center of the tube furnace In the constant temperature area, sulfur powder (1.5g) is placed in the loading boat-3 in the high-temperature tube furnace 11, so that it is located at the upstream position of the air flow, and the sulfur powder can be heated separately with the heater-5, and the sapphire substrate 7 Placed in the main transport pipe 1 of the sulfur vapor of the high-temperature tube furnace 11 so that it is located 20mm below the gas outlet of the tungsten source steam, and 25sccm and 100sccm argon are respectively introduced into the main transport pipe 1 and the secondary transport pipe 2 Gas is used as the carrier gas, and the gas outlet end of the high-temperature tube furnace 11 is pass...

Embodiment 2

[0044] The method for preparing a single-layer continuous atomic layer film of tungsten disulfide comprises the following steps: placing tungsten trioxide (300 mg) in the carrier boat 2 4 in the quartz high-temperature tube furnace 11, so that the tungsten trioxide is positioned at the center of the tube furnace In the constant temperature area, sulfur powder (1.2g) is placed in the loading boat-3 in the high-temperature tube furnace 11, so that it is located at the upstream position of the air flow, and the sulfur powder can be heated separately with the heater-5; the sapphire substrate 7 Place it in the main transport pipe 1 of the sulfur vapor of the high-temperature tube furnace so that it is located 20 mm below the gas outlet of the tungsten source steam. In 2, a mixed gas of 120 sccm argon and 10 sccm hydrogen is introduced as a carrier gas, and the outlet end of the high-temperature tube furnace 11 is fed into the exhaust gas treatment device 10 after being treated and t...

Embodiment 3

[0049] The method for preparing a multilayer continuous molybdenum disulfide atomic layer film comprises the following steps: molybdenum trioxide (500mg) is placed in the loading boat 2 4 in the quartz high-temperature tube furnace 11, and the molybdenum trioxide is placed in the tube furnace In the central constant temperature area, sulfur powder (1.8g) is placed in the loading boat-3 in the high-temperature tube furnace 11, so that it is located at the upstream position of the air flow, and the sulfur powder can be heated separately with the heater-5, and the sapphire substrate 7. Place it in the main transport pipe 1 of the sulfur vapor of the high-temperature tube furnace 11 so that it is located 20 mm below the gas outlet of the tungsten source steam, and feed 30 sccm argon into the main transport pipe 1 and the secondary transport pipe 2 respectively as Carrier gas, a mixed gas of 120 sccm argon and 10 sccm hydrogen is passed into the secondary transport pipe 2 as a carri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com