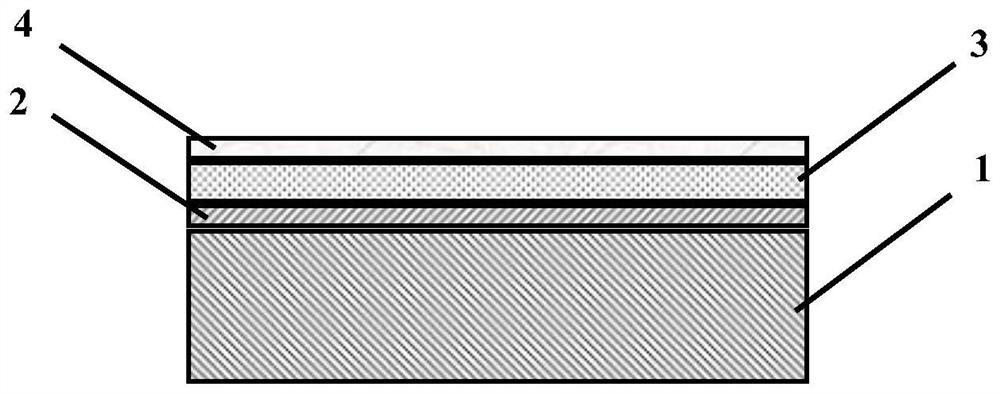

A rapid construction high-durability concrete protection system and its preparation method

A technology of durable concrete and protection system, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of long construction period and poor environmental adaptability, and achieve high construction efficiency, excellent waterproofing, and good environmental adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

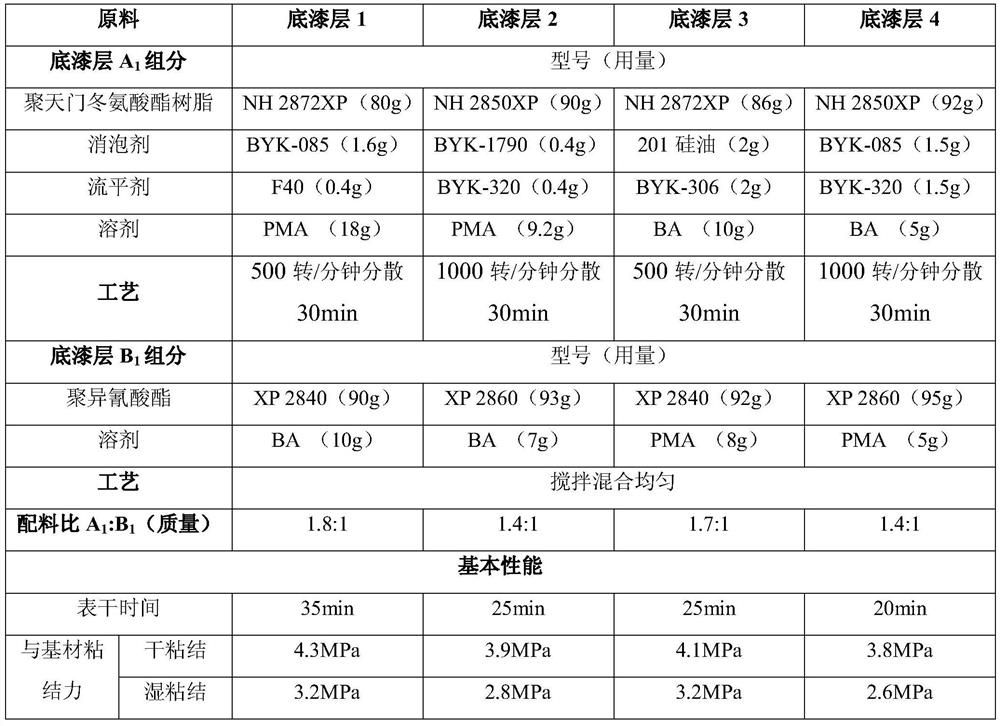

[0076] Add polyaspartic acid ester resin, defoamer, leveling agent, and solvent into the container, and disperse at 500-1000 rpm for 30 minutes to prepare component A 1 ; Mix polyisocyanate and solvent evenly by mass ratio to obtain component B 1 .

[0077] Table 1 Primer layer material ratio and process parameters

[0078]

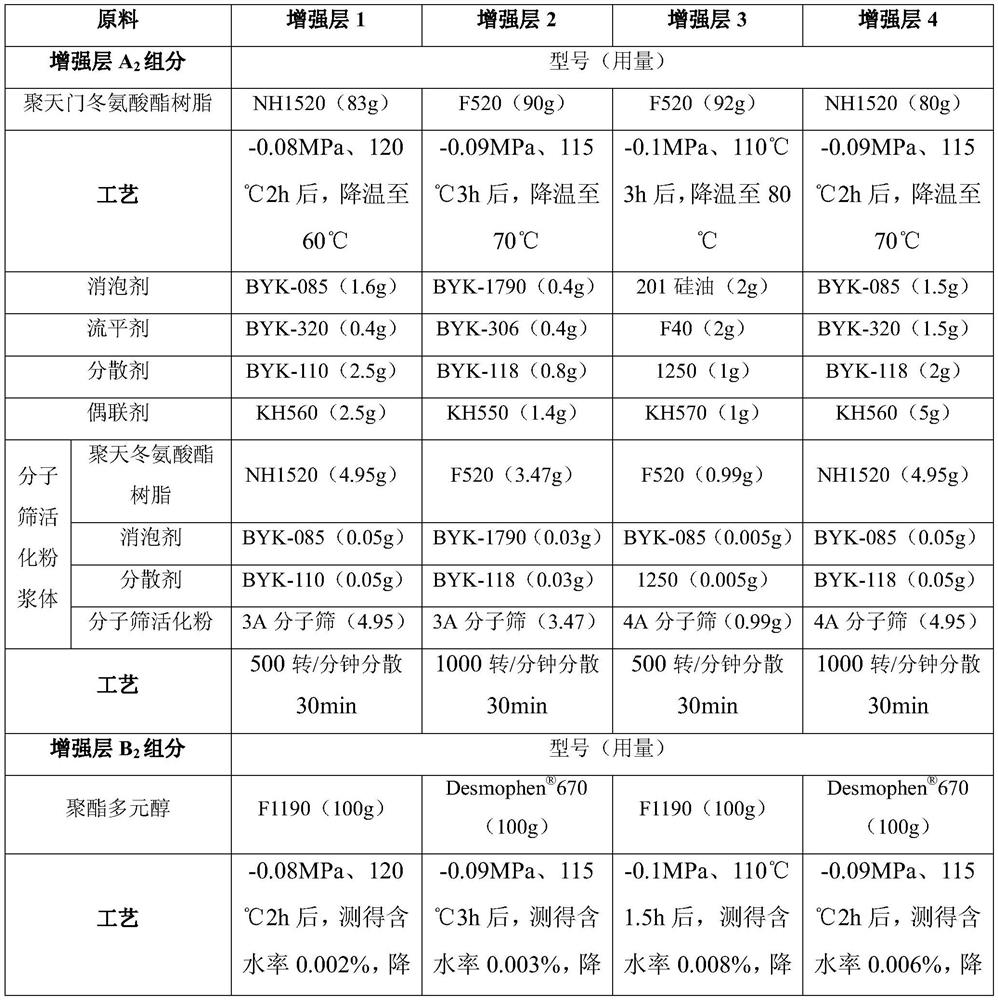

[0079] (2) Preparation of polyaspartic acid ester elastic reinforcement layer

Embodiment 5-8

[0081] polyaspartate resin P 2 Put it into the container, remove water under vacuum at -0.08~-0.1MPa, 110℃~120℃ for 1~3h, then cool down to 60~80℃, add defoamer, leveling agent, coupling agent and Molecular sieve activated powder slurry X, dispersed at 500-1000 rpm for 30 minutes to prepare component A 2 ;Put the polyester polyol into the container, vacuum degree -0.08~-0.1MPa, dehydration at 110~120℃ for 1.5~3h, the moisture content measured by the Karl Fischer method is less than 5 / 10,000, blow nitrogen or dry Release the vacuum with air, lower the temperature to 68-75°C, add aliphatic isocyanate monomer and catalyst, react at a constant temperature for 30-40 minutes, then raise the temperature to 75-85°C and react at a constant temperature for 2-3 hours, use the toluene di-n-butylamine method, see GB / T 12009.4-1989, the measured final isocyanate content reaches the final NCO% theoretical residue designed before the polymerization reaction, and the component B is obtained ...

Embodiment 9-12

[0087] polyaspartate resin P 3 , fluorocarbon resin, hydroxyl-terminated polydimethylsiloxane, dispersant, pigments and fillers are added to the container, and the water is removed in vacuum at -0.08~-0.1MPa, 110℃~120℃ for 1~3h, and the temperature is lowered to 60 ~80°C, add defoamer, leveling agent, and molecular sieve activated powder slurry Y to the above container, and disperse at 500~1000 rpm for 30 minutes to prepare component A 3 ; Mix polyisocyanate and solvent evenly by mass ratio to obtain component B 3 .

[0088] Table 3 Topcoat material ratio and process parameters

[0089]

[0090]

[0091]

[0092] (4) Protection system construction

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com