Emulsion-type water-based cleaning agent for oily sludge and preparation method and application method thereof

A water-based cleaning agent and emulsion type technology, which is used in the preparation of water-based cleaning agents and the field of emulsion-based water-based cleaning agents, can solve the problems of limited application, waste of resources, low interfacial tension, etc., and achieve a wide range of applications and treatment effects. Good, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

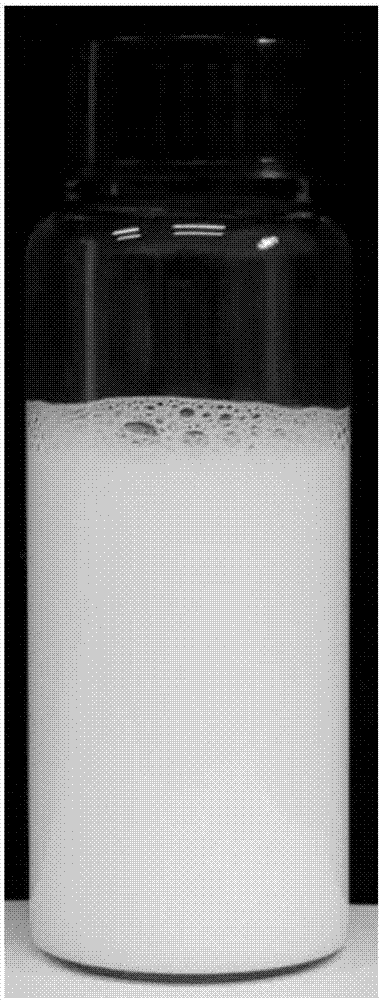

[0020] Based on 100 parts by weight, respectively weigh 5 parts of AES (sodium fatty alcohol polyoxyethylene ether sulfate) and super amphiphile emulsifier, 10 parts of toluene, and 80 parts of pure water according to the ratio of mass ratio of 1:1, and put them in sequence. into the reactor, stirred at room temperature at a speed of 500 r / min for 40 minutes to form a uniform and stable emulsion-type water-based cleaning agent, its sample see figure 1 .

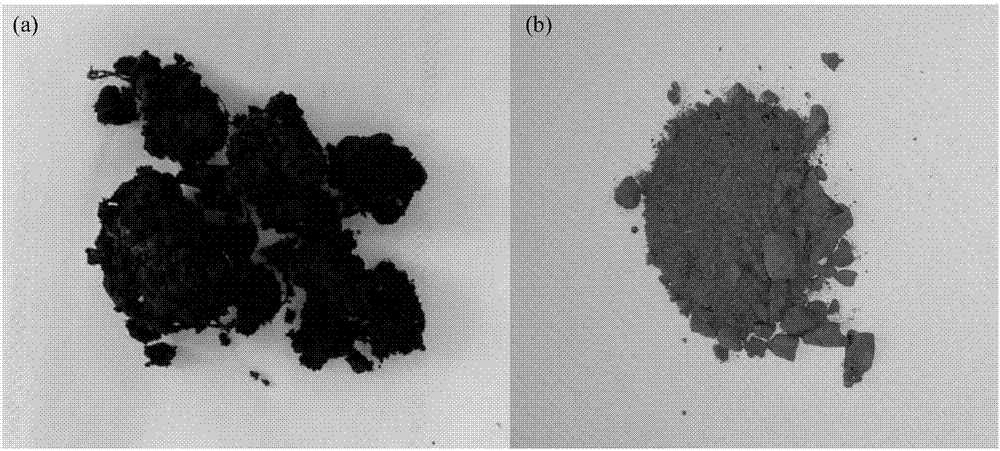

[0021] The oily sludge is taken from Liaohe Oilfield, and its initial parameters are oil content 57.20%, solid content 38.98%, water content 3.82% (the percentage is based on weight), and its macroscopic photos are shown in figure 2 Middle (a).

[0022] Cleaning effect test: the mass ratio of oily sludge to water-based cleaning agent is 1:4, wash with cleaning agent twice at 80°C, each time for 30 minutes, at a speed of 500 rpm, and then rinse with hot water at 80°C for 1 Each time, after cleaning with cleaning agent and w...

Embodiment 2

[0029] In 100 parts by weight, 6 parts of surfactants (AES and super amphiphile emulsifier mass ratio 2:1 or 1:4 or 4:1) were weighed according to AES (sodium fatty alcohol polyoxyethylene ether sulfate) and super amphiphile emulsifier Molecular emulsifiers are respectively 4 parts and 2 parts, 1.2 parts and 4.8 parts, 4.8 parts and 1.2 parts), toluene 8.5 parts, pure water 85.5 parts.

[0030] Put the surfactant, toluene and pure water into the reactor in sequence, and stir at 300 rpm for 30 minutes at room temperature to form three kinds of emulsion-type water-based cleaning agents with different surfactant mass ratios.

[0031] The oily sludge is taken from Liaohe Oilfield, and its initial parameters are oil content 57.20%, solid content 38.98%, water content 3.82% (the percentage is based on weight), and its macroscopic photos are shown in figure 2 Middle (a).

[0032] Cleaning effect test: the mass ratio of oily sludge to water-based cleaning agent is 1:4, wash with cle...

Embodiment 3

[0038] Based on 100 parts by weight, weigh 1 part each of AES (sodium fatty alcohol polyoxyethylene ether sulfate) and super amphiphilic emulsifier, 3 parts of oil-soluble components, and 3 parts of oil-soluble components according to the ratio of 1:1 by mass. It is mixed benzene or xylene or paraffin oil or gas oil or diesel oil, and 95 parts of pure water.

[0039] Put AES, super amphiphile emulsifier, an oil-soluble component and the water phase into the reactor in sequence, and stir at 150 rpm for 25 minutes at room temperature to form emulsion-type water with 5 different oil-soluble components. base cleaner.

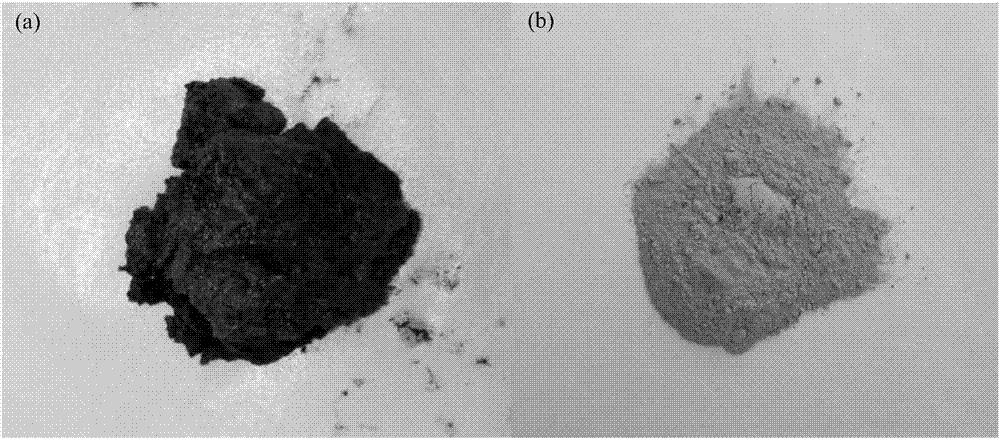

[0040] The oily sludge is taken from Shengli Oilfield. Its initial parameters are oil content 8.13%, solid content 41.59%, and water content 50.28%. The macroscopic photo is shown in image 3 Middle (a).

[0041] Cleaning effect test: the mass ratio of oily sludge to water-based cleaning agent is 1:4, wash once with cleaning agent at 60°C, 10 minutes each time, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Residual oil rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com